A Measuring Device for Large Size Optical Fiber Preform

A technology of optical fiber preform and measuring device, which is applied in the direction of measuring device, optical device, optical instrument test, etc., can solve the problem of increasing the cost of large-size optical fiber preform measuring device, the price of photosensitive position sensing element is relatively expensive, and the position of detector Error increase and other problems, to achieve the effect of reasonable and simple structure setting, small error and large measurement diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

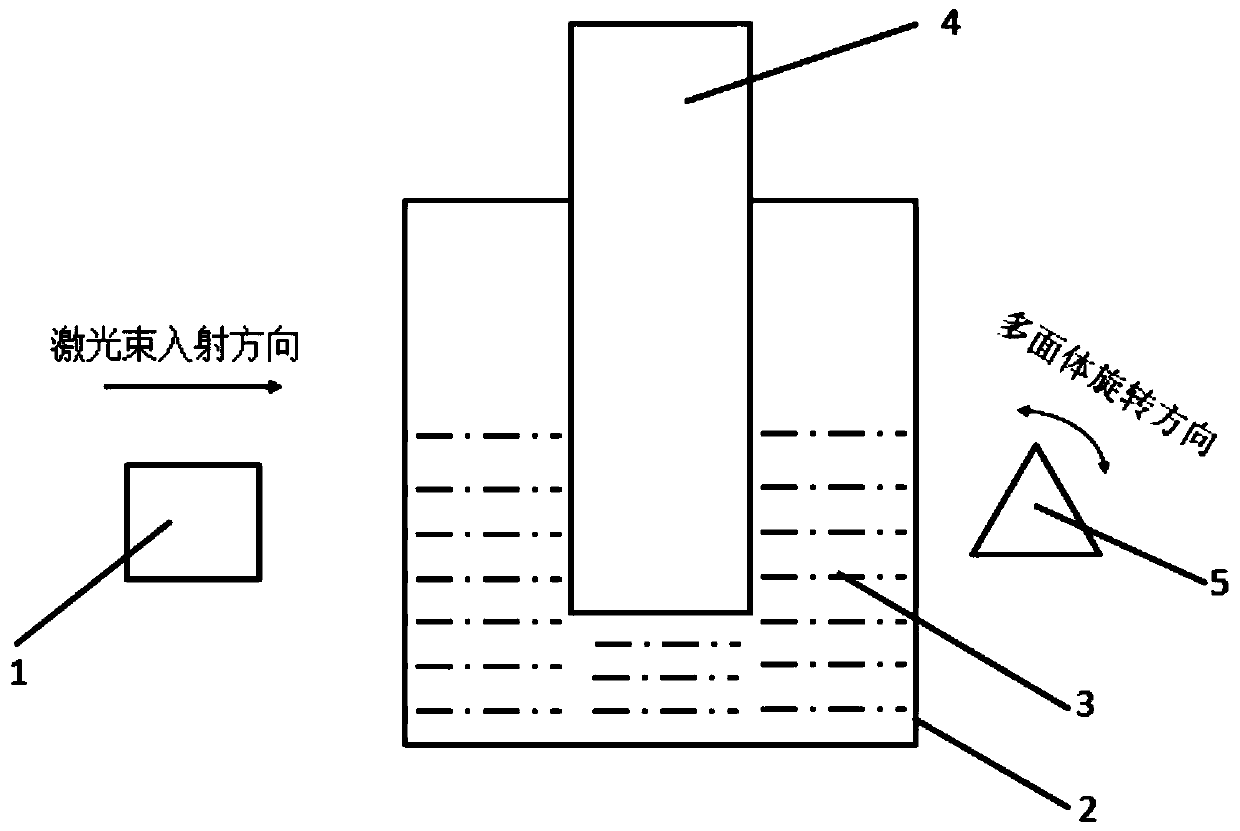

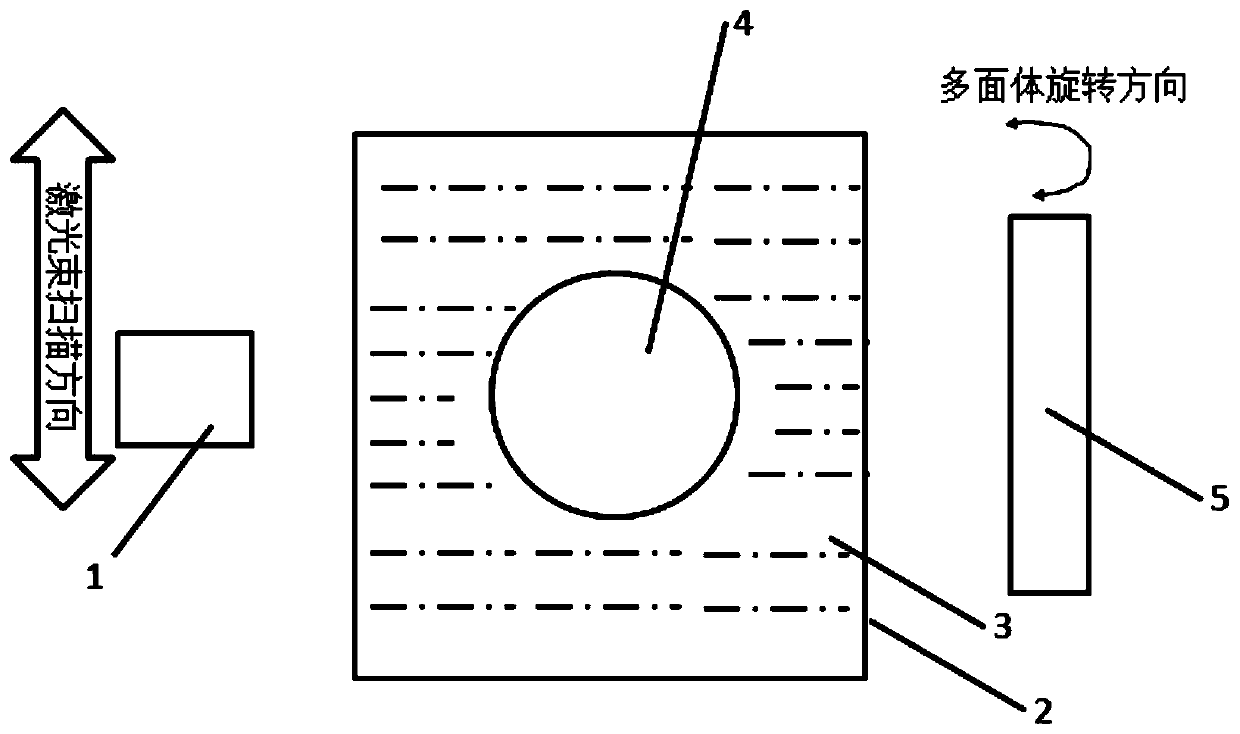

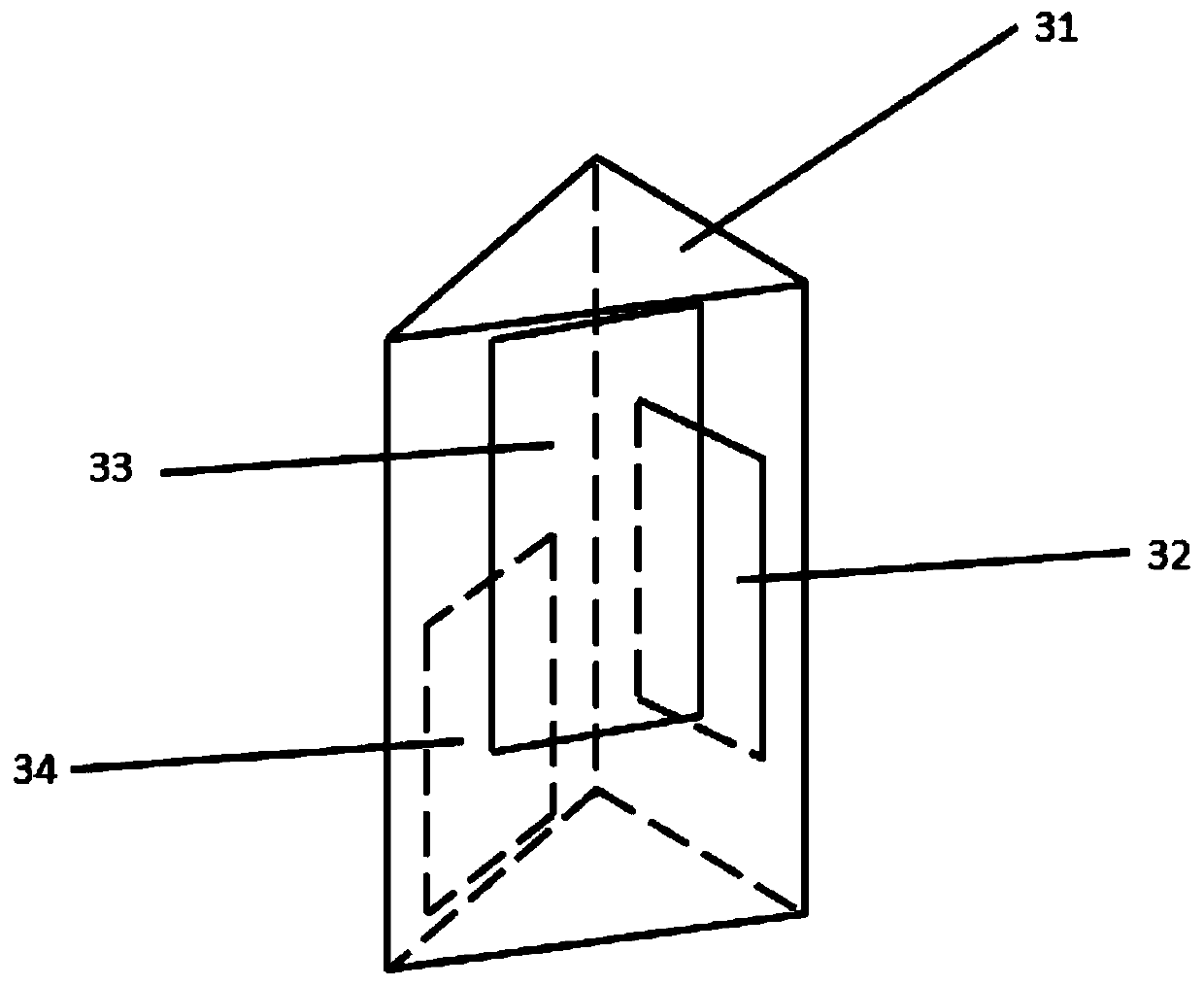

[0021] It includes a light-transmitting container 2. The light-transmitting container is a rectangular cross-section light-transmitting container with an open top and is made of pure silicon dioxide. The light-transmitting container is filled with matching oil 3. The matching oil can be silicone oil. Matching oils have the same or similar refractive index as pure silica glass. An optical fiber preform clamping device is arranged above the middle part of the light-transmitting container. A scanning laser light source 1 is installed on the outer side of the light-transmitting container, and the scanning laser light source is connected with a horizontal displacement device, which can reciprocate the scanning laser light source in the horizontal direction to move the optical fiber preform 4 placed in the matching oil of the light-transmitting cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com