Pile-supported type reinforced embankment three-dimensional deformation field visual test device and test method thereof

A reinforced embankment, three-dimensional deformation technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of uneven deformation of the water bag surface, inability to obtain the three-dimensional deformation field of the soil, inconvenient installation and disassembly, etc., to achieve saving Cost and time, the realization of visual observation, the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

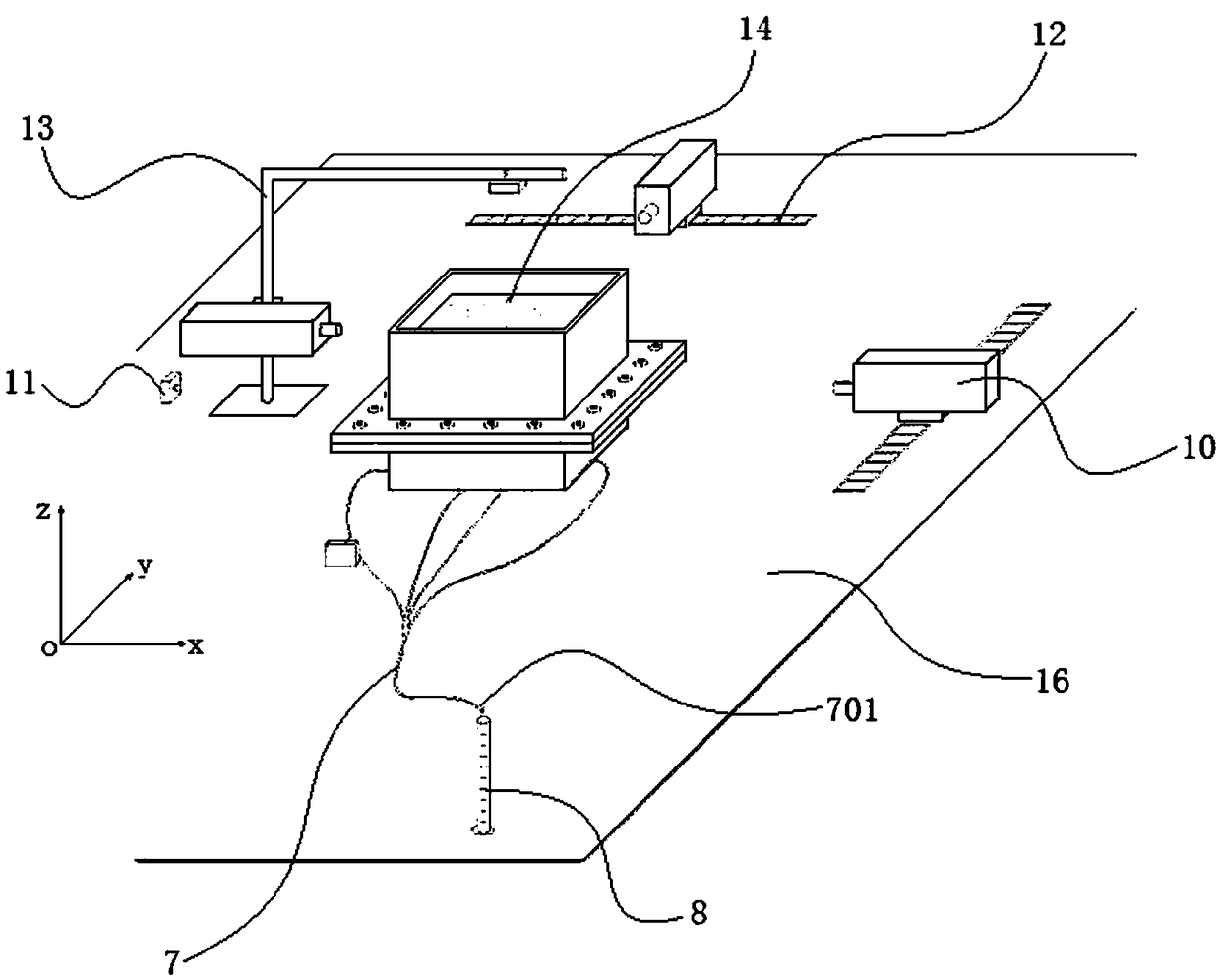

[0052]This embodiment discloses a three-dimensional deformation field visualization test device for a pile-supported reinforced embankment, including a model groove existing in an o-xyz orthogonal coordinate system, nine model piles 3 and nine pile caps 4 .

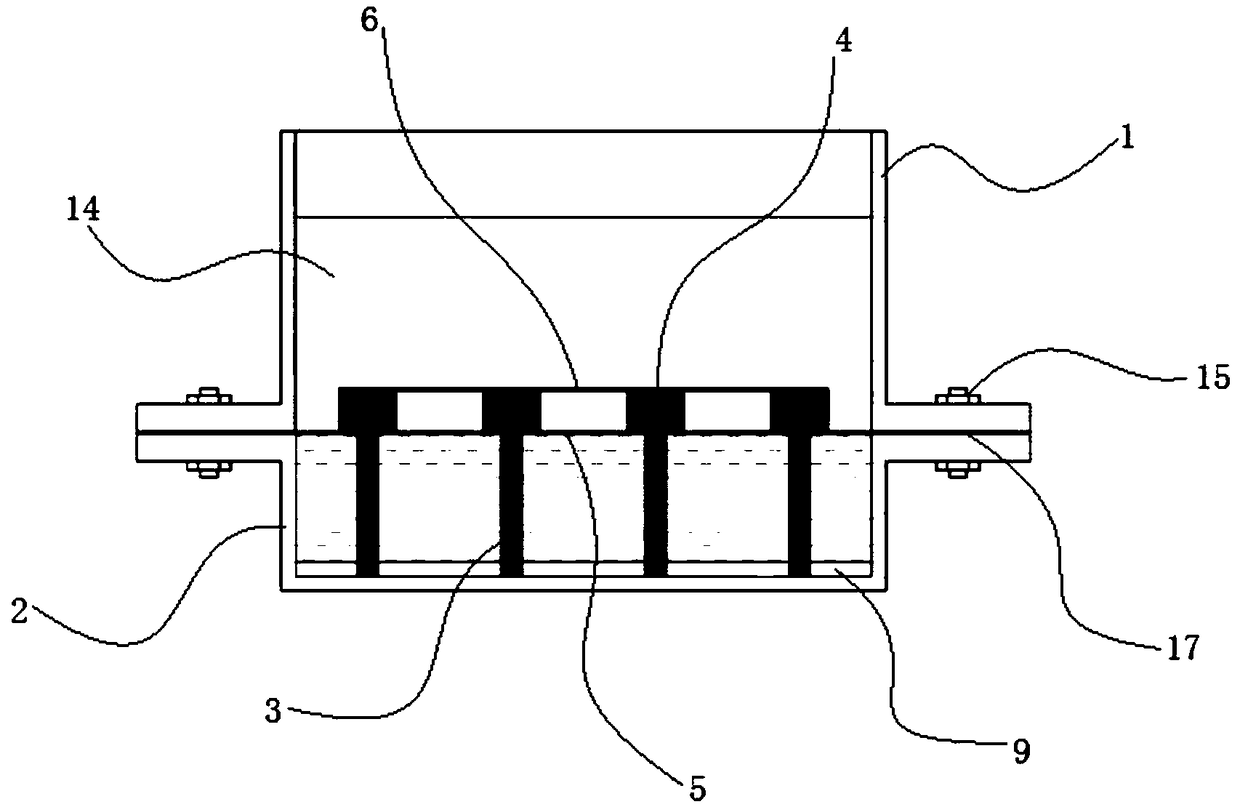

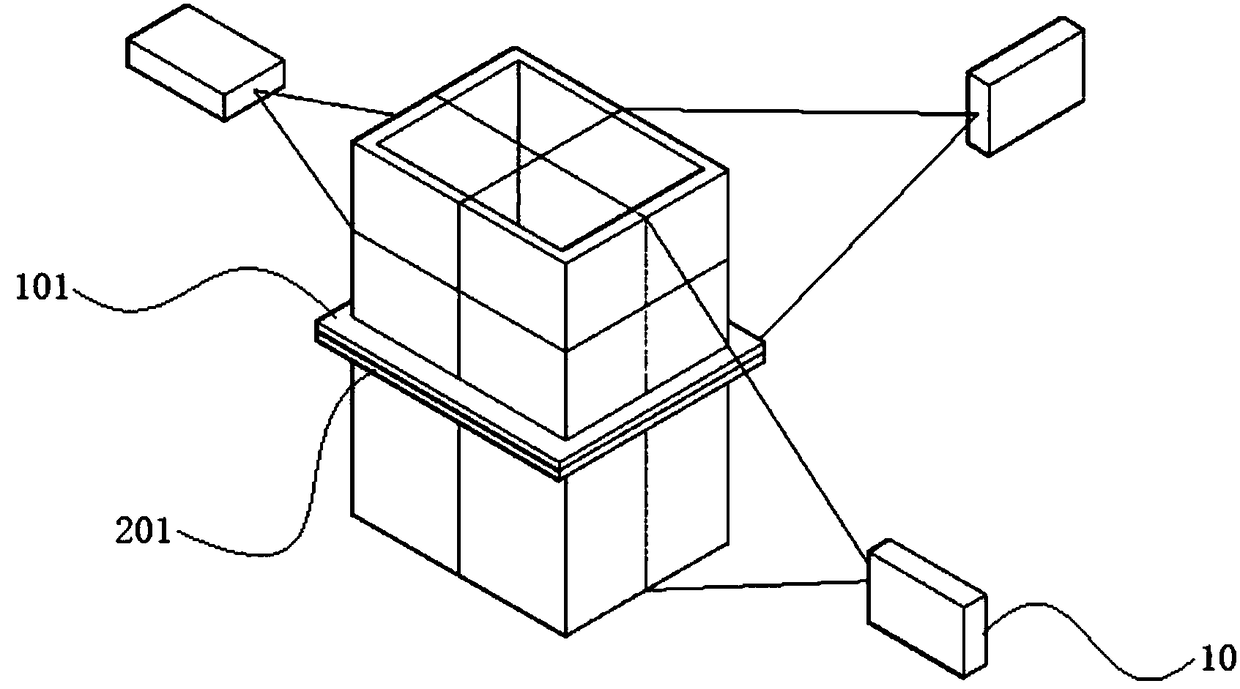

[0053] see figure 2 and image 3 , the model tank is made of transparent plexiglass, and the whole is a rectangular box. The mold tank can be divided into an upper mold tank 1 and a lower mold tank 2 .

[0054] The upper mold tank 1 is a rectangular frame as a whole. The lower end of this rectangular frame has an outer curl I101.

[0055] The lower mold tank 2 as a whole is a rectangular box. The upper end of this rectangular box has an outer crimp II 201 . A positioning plate 9 is arranged at the bottom of the lower mold tank 2 . see Figure 7 , there are 9 grooves 901 for the model pile 3 to be embedded on the surface of the positioning plate 9 . The positioning plate 9 is processed according to the test plan, ...

Embodiment 2

[0063] This embodiment discloses a three-dimensional deformation field visualization test device for a pile-supported reinforced embankment, including a model groove existing in an o-xyz orthogonal coordinate system, 16 model piles 3 and 16 pile caps 4 .

[0064] The model tank is made of transparent tempered glass, and the whole is a rectangular box. The mold tank can be divided into an upper mold tank 1 and a lower mold tank 2 .

[0065] The upper mold tank 1 is a rectangular frame as a whole. The lower end of this rectangular frame has an outer curl I101. A sealing gasket 17 is attached to the bottom of the outer curling I101. The gasket 17 is made of rubber material. The maximum side length of the inner cavity of the upper model groove 1 is 19cm, and the height is 22cm.

[0066] The lower mold tank 2 as a whole is a rectangular box. The upper end of this rectangular box has an outer crimp II 201 . The maximum side length of the cavity of the lower model groove 2 is 1...

Embodiment 3

[0075] This embodiment discloses a test method using the test device described in embodiment 1 or 2, comprising the following steps:

[0076] 1) Experimental design: read relevant literature, consult information, draw up a test plan, and determine the specific test parameters for each group of working conditions. Among them, the test parameters include the size of the model groove, the shape and size of the pile cap 4, the pile distance, the form of pile arrangement, the filling height, the relative compactness of the filling, and the displacement.

[0077] 2) Model making: Make a model according to the test plan. Clean the model tank and the model pile 3 to prevent the prepared transparent soil 14 from being polluted and affect the experimental results.

[0078] 3) Fix the lower model tank 2, the laser 10 and the high-speed CCD camera 11 on the optical table.

[0079] 4) Lay out model piles 3 .

[0080] 5) Close the drain valve 701 and inject water into the lower model tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com