Networking control system for flat knitting machine provided with self-running type yarn guide

A control system and self-running technology, applied in the field of flat knitting knitting machine control, can solve the problem that the yarn feeder of the flat knitting machine cannot be controlled independently, and achieve the effect of ensuring efficient operation and strong expansibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

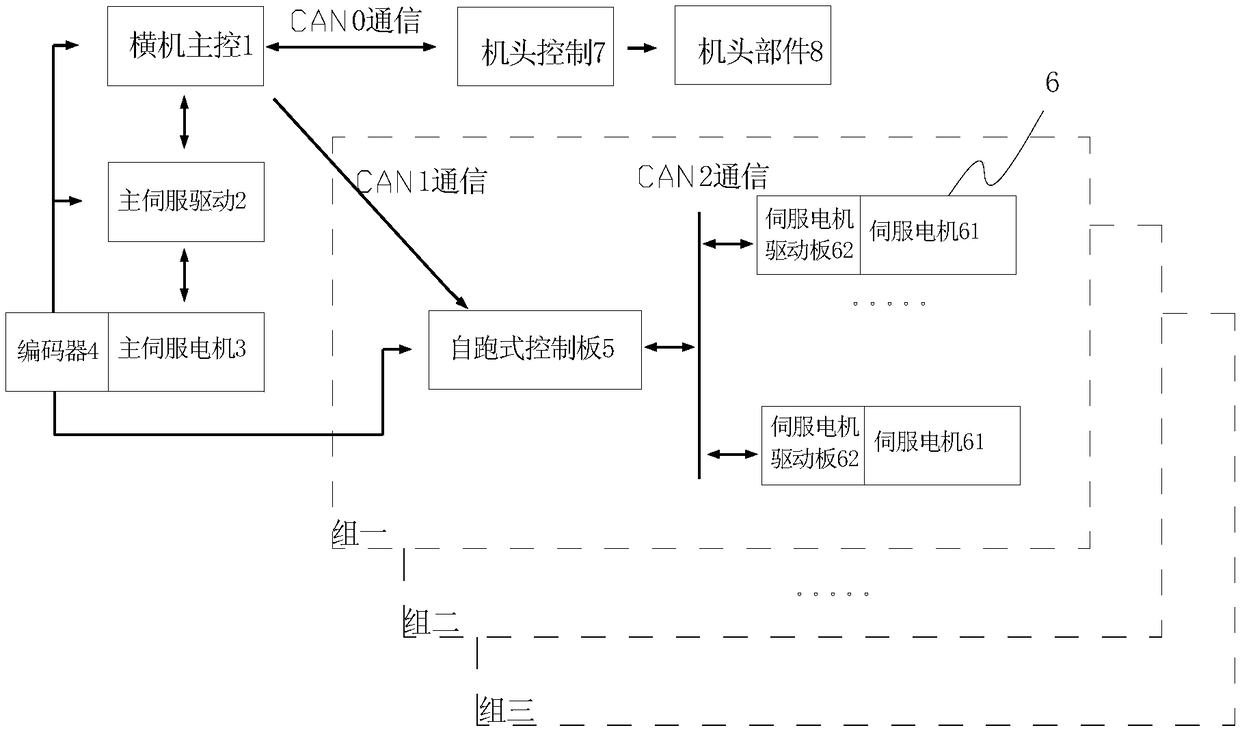

[0022] combined as Figure 2-5 , the present invention will be further described.

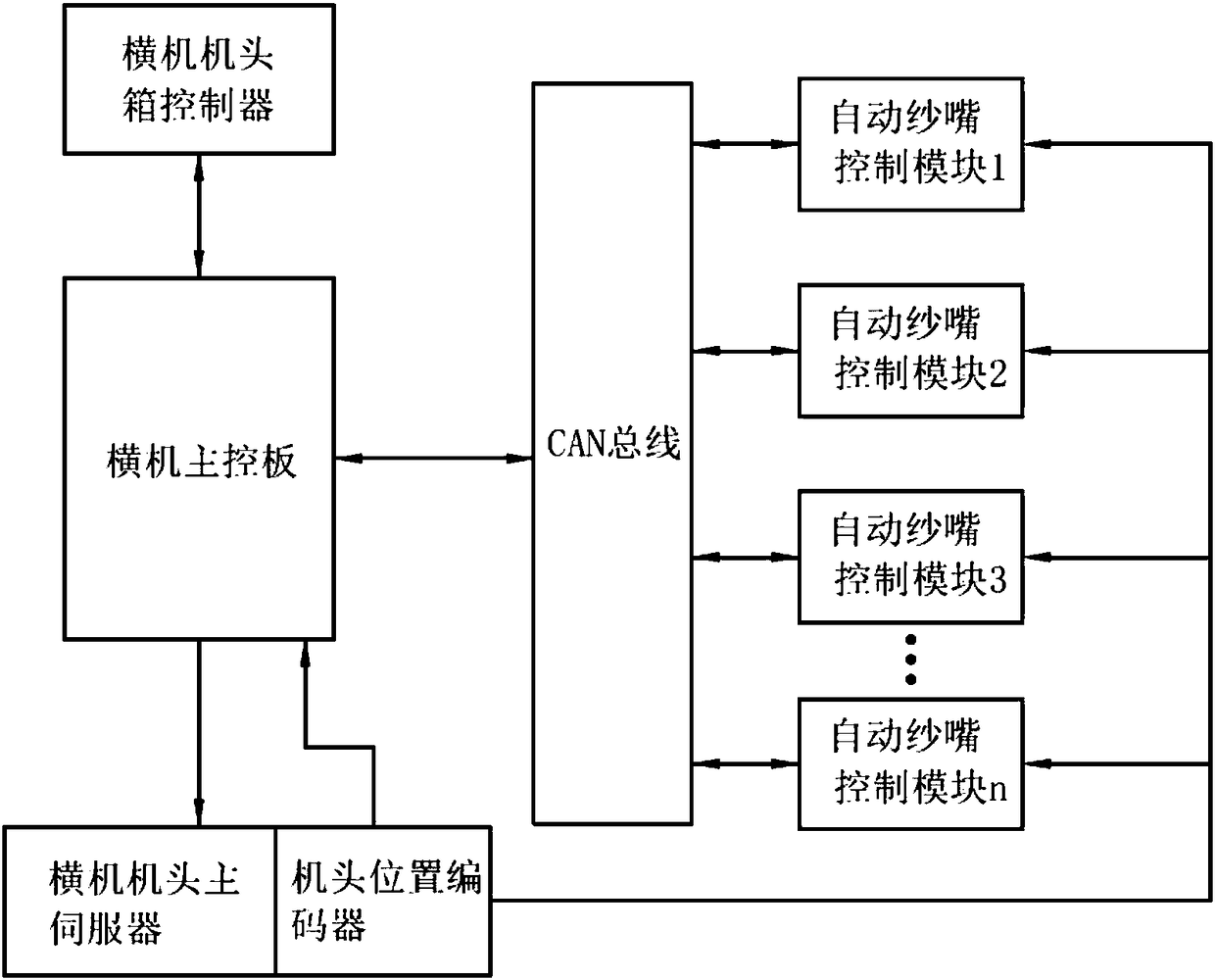

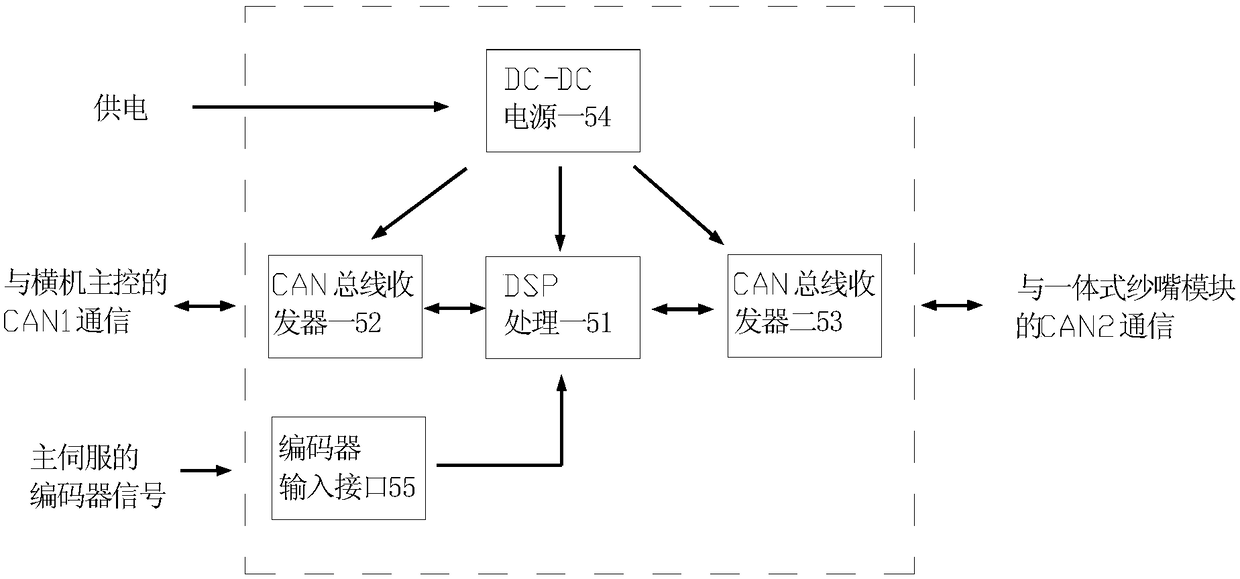

[0023] The network control system of the flat knitting machine with self-running yarn feeder mainly includes the flat knitting machine host 1, the main servo drive 2, the main servo motor 3, the encoder 4 on the main servo motor 3, the self-running control board 5, the integrated type Yarn feeder module 6 , head control board 7 , head part 8 .

[0024] The bus of the flat knitting machine host 1 includes two paths, one is the head control board 7 for CAN0 bus communication, and the head control board 7 controls the head part 8 to execute commands. The other way is CAN1 bus communication, which mainly communicates with the self-running control board 5 and the integrated yarn feeder module 6, which is the technical focus of the present invention. The flat knitting machine host 1 is connected to the main servo drive 2 and the main servo motor 3 in sequence. The encoder 4 signal on the main servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com