A method of installing antique rivets

An installation method and rivet technology, which can be applied to ships and other directions, can solve the problems that the outer plate of the hull is easily welded in a large area, the internal coating is easily damaged, and the construction period is prolonged, so as to save the cost of paint and labor, and to achieve a smooth appearance. The effect of smooth and reduced construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

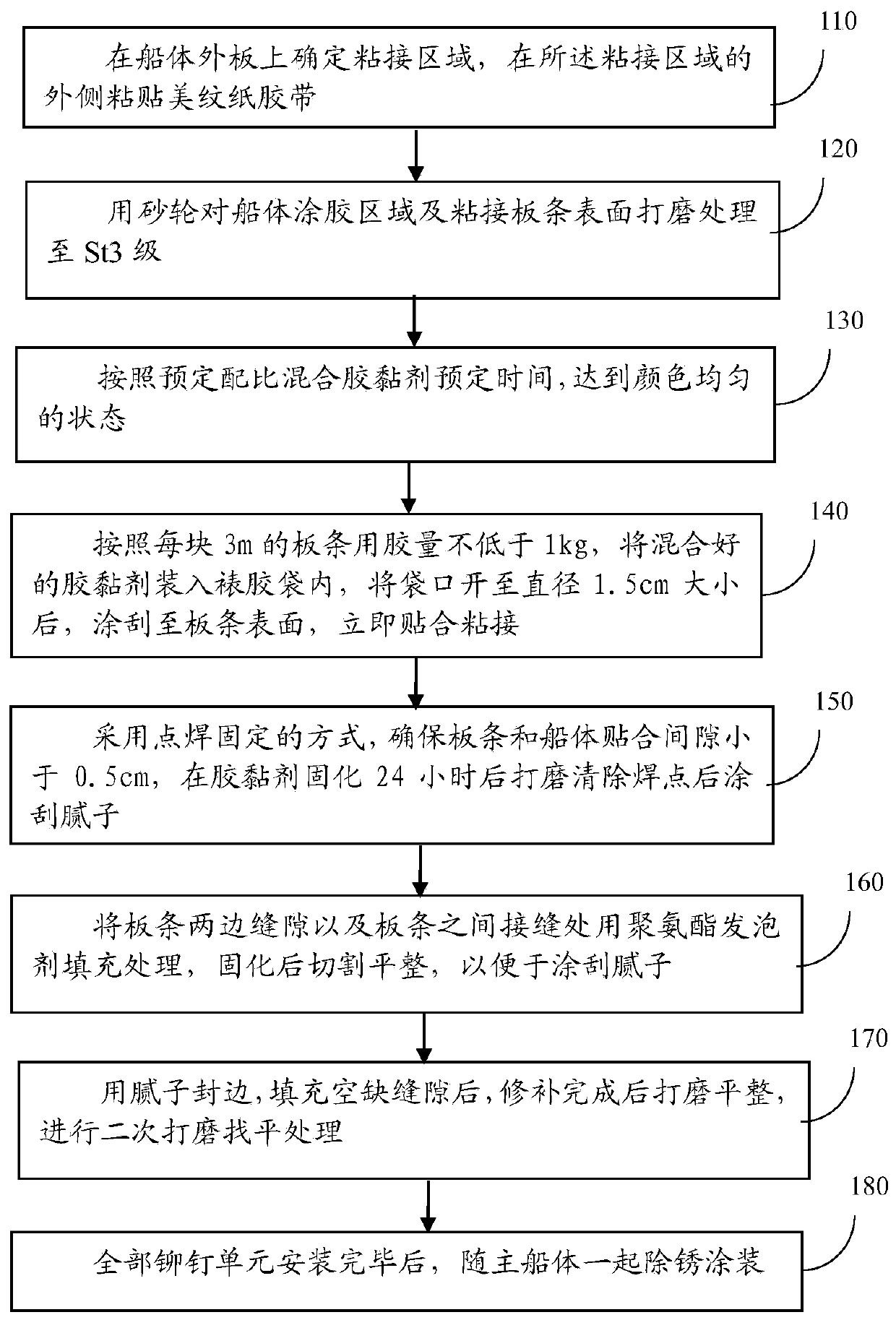

[0027] figure 1 It is a schematic flowchart of a method for installing antique rivets in an embodiment of the present invention. like figure 1 As shown, the method includes:

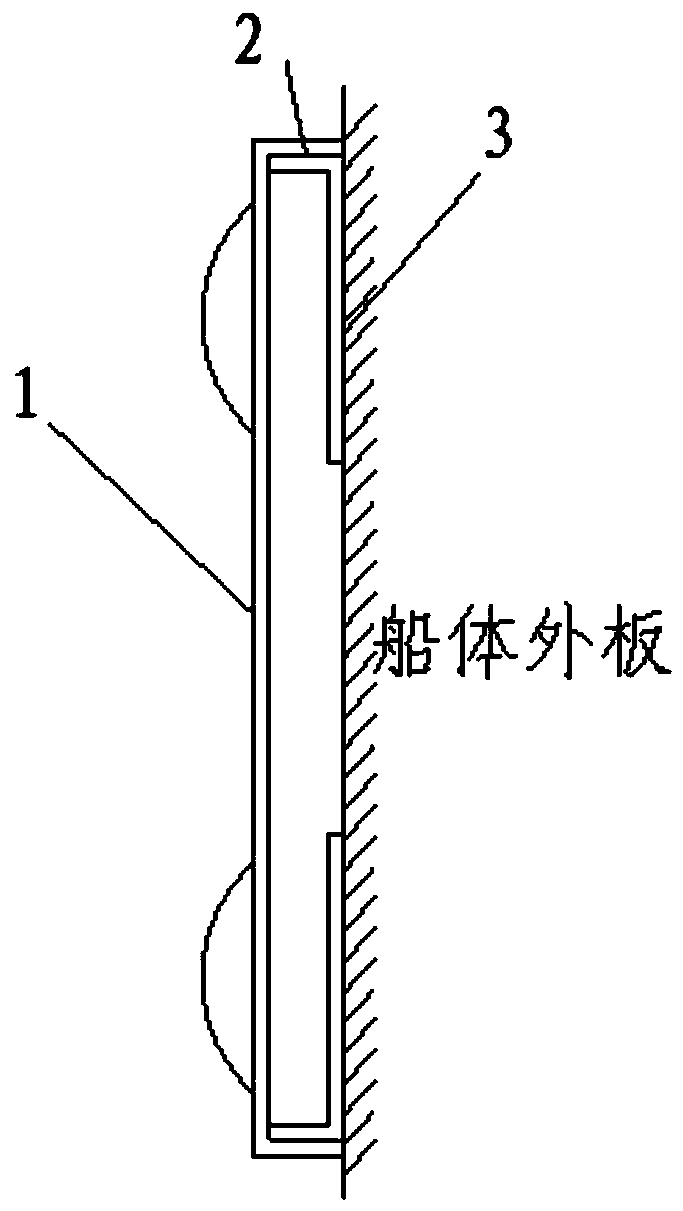

[0028] Step 110: Determine the bonding area 3 on the outer panel of the hull, and paste masking tape on the outside of the bonding area 3;

[0029] Further, the bonding area 3 is determined by using the elastic line of the ink fountain.

[0030] Specifically, firstly, the bonding area 3 is determined by the elastic line of the ink fountain on the outer panel of the ship. After the bonding area 3 is determined, the masking tape is pasted on the outside of the bonding area 3. The number of elastic lines of the ink fountain can be selected according to the actual situation, and the sticking position of the masking tape is outside the edge of the drawn line, thereby achieving the technical effect of protecting the surface of the outer coating and reducing the pollution of residual glue.

[0031] Step 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com