Manufacturing technology of 718 alloy small-bore precise pipe

A manufacturing process and small-diameter technology, applied in the field of alloy manufacturing, can solve problems such as difficult to obtain surface quality pipe blanks, no 718 alloy small-diameter seamless pipe manufacturing process, and difficult cold working.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment.

[0020] The intermediate tube with a specification of Φ12.7x1.3mm should be used, and its chemical composition should meet the requirements of Table 1. The surface of the incoming pipe should be smooth and clean, and there should be no visible scale, oil, metal scales and other foreign matter on the inner and outer surfaces, and there should be no cracks, folds, pits, scratches, foreign matters, rust spots, etc. on the inner and outer surfaces that affect the quality of the subsequent cold-rolled surface. exist.

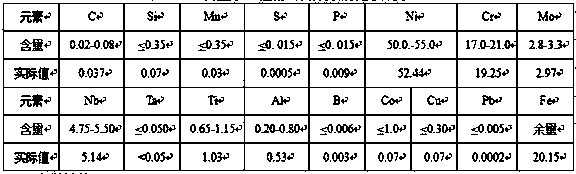

[0021] Table 1 Chemical composition requirements of 718 alloy precision tube (wt%)

[0022]

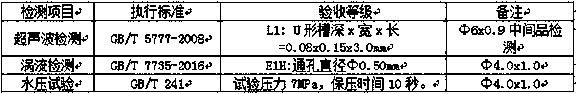

[0023] For the target product specification of Φ4*1.0mm small-diameter precision tube, outer diameter tolerance ±0.04mm, wall thickness tolerance (-0.1~+0), the specific cold deformation process requirements of one of the patented technology implementations are shown in Table 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com