Energy-saving environment-friendly multiple-stage centrifugal pump

An energy-saving and environmental-friendly centrifugal pump technology, which is applied in the direction of pumps, piston pumps, pump devices, etc., can solve the problems of large power consumption and waste of energy, and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further detailed explanation through specific implementation mode below:

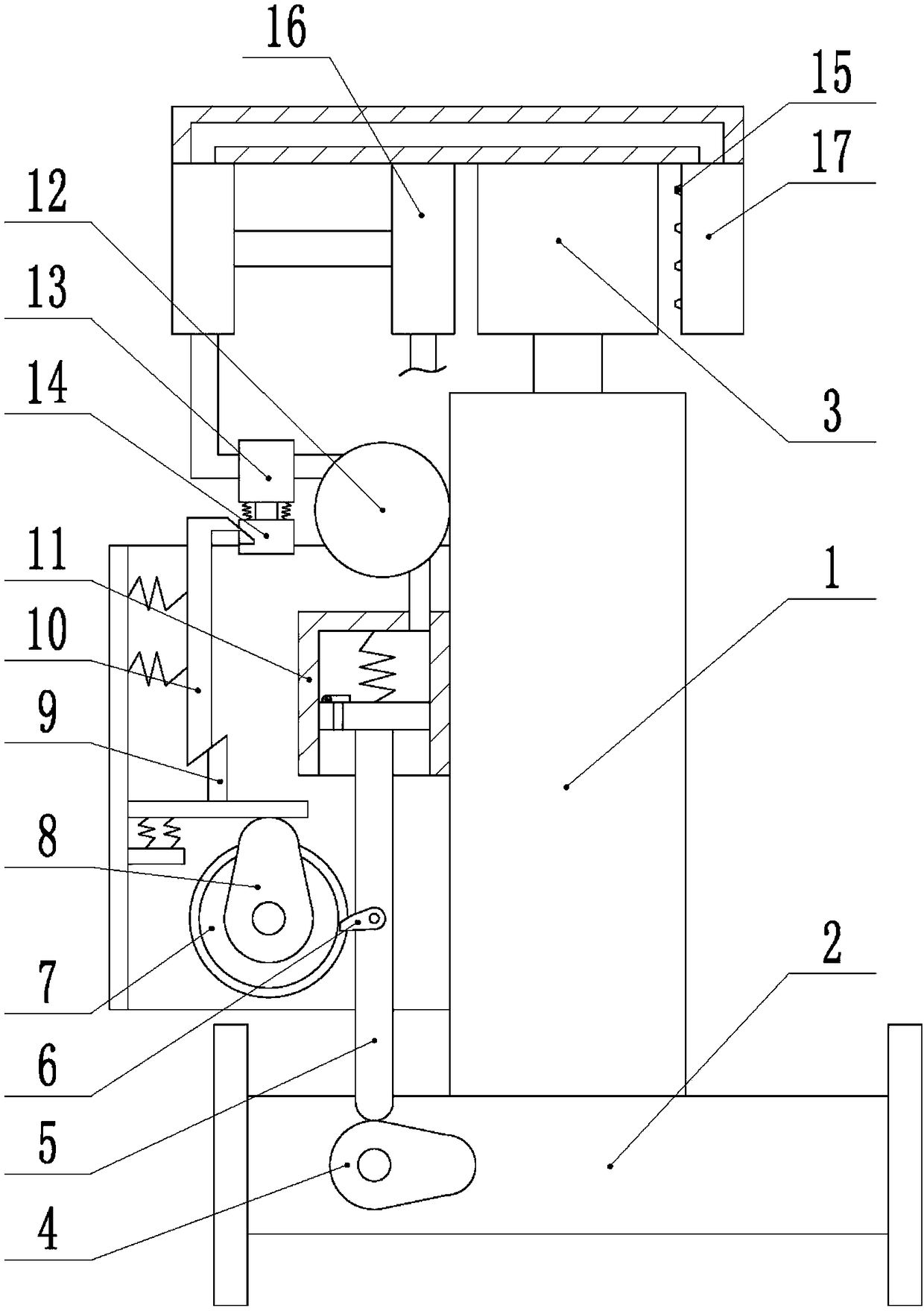

[0015] The reference signs in the accompanying drawings include: pump body 1, water pipe 2, motor 3, first cam 4, piston rod 5, pawl 6, ratchet 7, second cam 8, first wedge rod 9, second Wedge bar 10, air pump 11, air bag 12, slide valve 13, valve stem 14, air nozzle 15, collection box 16, air injection pipe 17.

[0016] The embodiment is basically as attached figure 1 Shown: Energy-saving and environment-friendly multistage centrifugal pump, including frame, pump body 1, motor 3 and water delivery pipe 2, pump body 1, motor 3 and water delivery pipe 2 are all installed on the frame, motor 3 is installed on pump body 1 At the top, a cooling fin is installed on the casing of the motor 3, and the water delivery pipe 2 is installed at the bottom of the pump body 1. The first turbine is rotatably connected to the water delivery pipe 2, and the first cam 4 is rotatably connected to the water delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com