Ultrasonic measuring probe suitable for on-line detection at high temperature

A technology for measuring probes and ultrasonic waves, applied to measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as poor signal-to-noise ratio, and achieve low cost, convenient implementation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

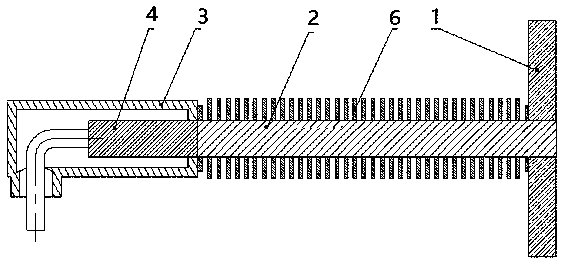

[0019] like figure 2 As shown, an ultrasonic measurement probe suitable for on-line detection at high temperature includes at least a support 1, a transducer cavity 3 and an ultrasonic transducer 4, the ultrasonic transducer 4 is connected in the transducer cavity 3, and the ultrasonic There is a waveguide 2 between the transducer 4 and the support 1, and the front end of the waveguide 2 is fixed to the support 1; the rear end of the waveguide 2 is connected to the ultrasonic transducer 4.

[0020] The waveguide 2 is made of composite material. The composite material is composed of a sound-conducting core material and a heat sink. The sound-conducting core material has a small sound resistance, is convenient for wave transmission, and has a large thermal resistance; the heat sink has good heat dissipation.

[0021] Fin-type heat sinks 6 are arranged around the waveguide 2 .

Embodiment 3

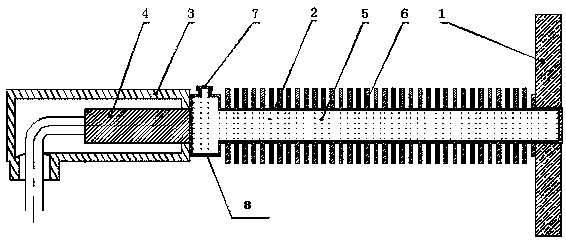

[0023] like figure 1 As shown, on the basis of Embodiment 1, the end of the sealed cavity 8 close to the ultrasonic transducer 4 has a liquid injection port 7 through which the high temperature waveguide oil 5 is injected.

[0024] The coupling agent of the present invention belongs to the prior art and can be purchased directly from the market.

[0025] When detecting a high-temperature measured object, part of the heat of the measured object radiates to space through the fin-shaped heat sink 6 , and the heat transmitted through the high-temperature waveguide oil 5 is limited, and has little influence on the ultrasonic signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com