2-acrylamido-2-methylpropyl sulfonic acid-based proton exchange membrane and preparation method thereof

A methylpropanesulfonic acid, proton exchange membrane technology, applied in fuel cells, electrochemical generators, electrical components, etc., can solve the problems of poor dimensional stability and low mechanical strength of proton exchange membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention firstly provides a kind of preparation method based on 2-acrylamide-2-methylpropanesulfonic acid proton exchange membrane, comprises the following steps:

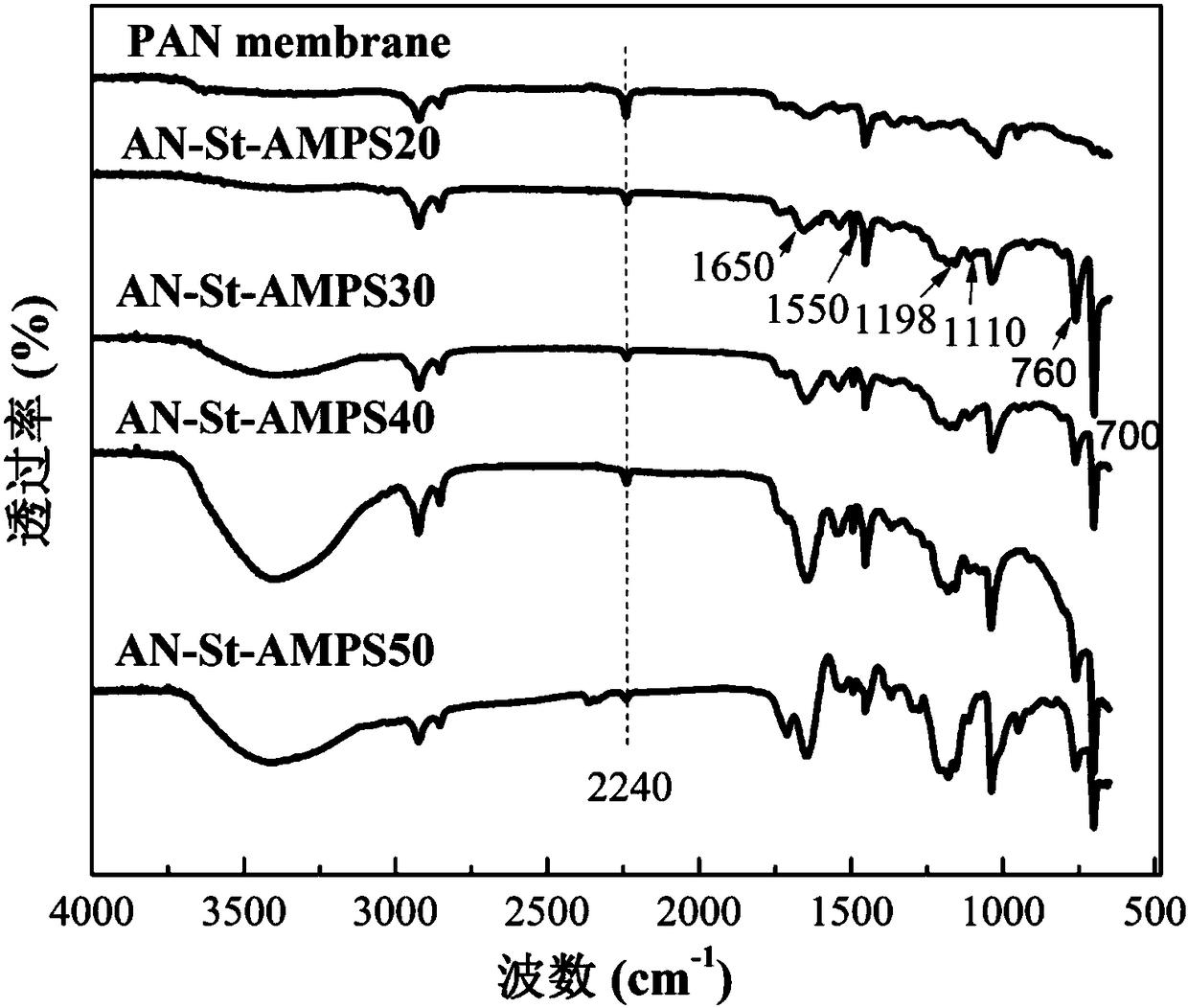

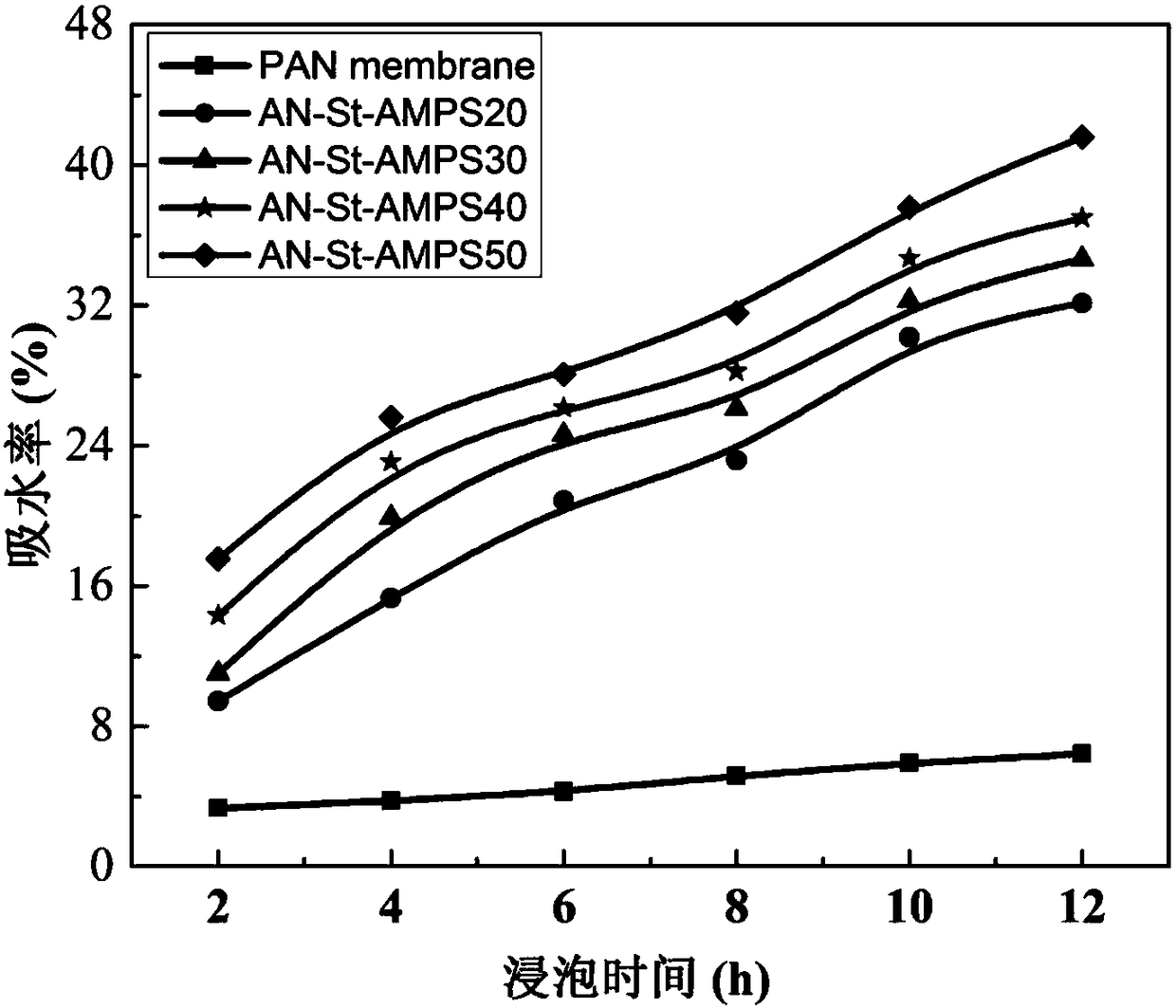

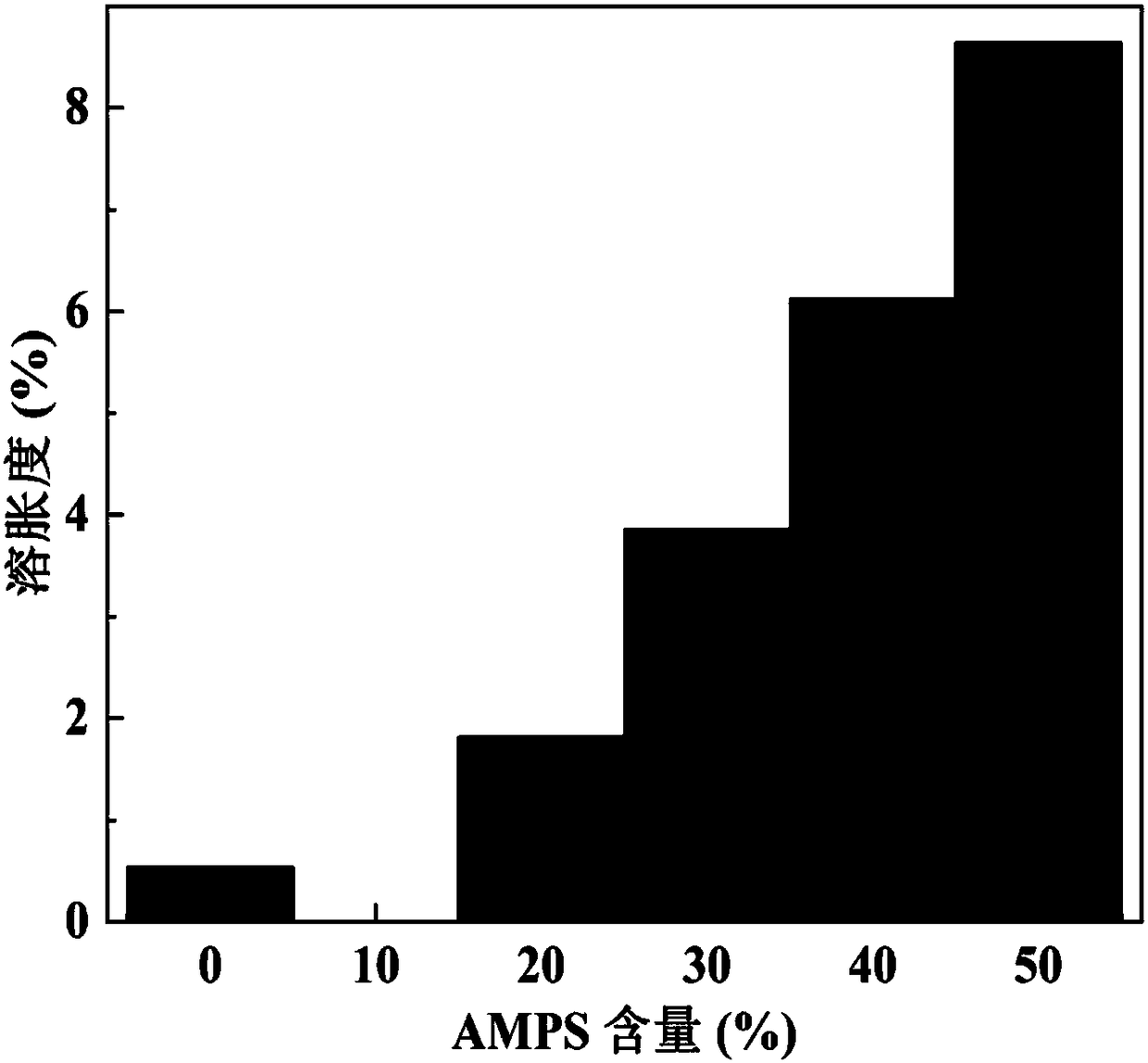

[0024] Step 1: first prepare acrylonitrile-styrene-2-acrylamide-2-methylpropanesulfonic acid (AN-St-AMPS) terpolymer by solution polymerization;

[0025] Step 2: The acrylonitrile-styrene-2-acrylamide-2-methylpropanesulfonic acid terpolymer obtained in step 1 is formed into a film by solution casting method to obtain a 2-acrylamide-2-methyl propanesulfonic acid proton exchange membrane.

[0026] According to the present invention, acrylonitrile-styrene-2-acrylamide-2-methylpropanesulfonic acid (AN-St-AMPS) terpolymer is prepared by solution polymerization first, specifically: 2-acrylamide-2- Put methylpropanesulfonic acid into the reaction container, add solvent to dissolve, the solvent is not particularly limited, preferably dimethyl sulfoxide; then add acrylonitrile and styrene monomer, heat ...

Embodiment 1

[0042] First, add 4g of 2-acrylamide-2-methylpropanesulfonic acid into the three-necked flask, add 80g of dimethyl sulfoxide, and place the three-necked flask in an oil bath, heat and stir to dissolve it, and then add 10.67g of Acrylonitrile and 5.33g styrene monomer, blow nitrogen for 30min to exclude oxygen, heat up to 60°C in a water bath, continue magnetic stirring, condense and reflux, finally add 0.022g AIBN to initiate the reaction, and continue the reaction for 8h to obtain AN-St-20% AMPS terpolymer;

[0043] Cast the obtained polymer solution (viscosity 54Pa·S) on a clean and dry glass plate to form a film, and dry it in a vacuum oven at 60°C for 24 hours to obtain the AN-St-20% AMPS proton exchange membrane.

Embodiment 2

[0045] First, add 6g of 2-acrylamide-2-methylpropanesulfonic acid into the three-necked flask, add 80g of dimethyl sulfoxide, and place the three-necked flask in an oil bath, heat and stir to dissolve it, and then add 9.33g of Acrylonitrile and 4.67g styrene monomer, blow nitrogen for 30min to exclude oxygen, heat up to 60°C in a water bath, continue magnetic stirring, condense and reflux, finally add 0.022g AIBN to initiate the reaction, and continue the reaction for 8h to obtain AN-St-30% AMPS terpolymer;

[0046] Cast the obtained polymer solution (viscosity of 60 Pa·S) on a clean and dry glass plate to form a film, and dry it in a vacuum oven at 60°C for 24 hours to obtain the AN-St-30% AMPS proton exchange membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com