Submicron water film deduster

A water-film dust collector and sub-micron technology, applied in deodorization, membrane technology, chemical instruments and methods, etc., can solve the problems of low purification efficiency, consumption of large water resources, and a large number of consumables, etc., to improve purification quality and high purification. Efficiency, ventilation and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The best implementation mode of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

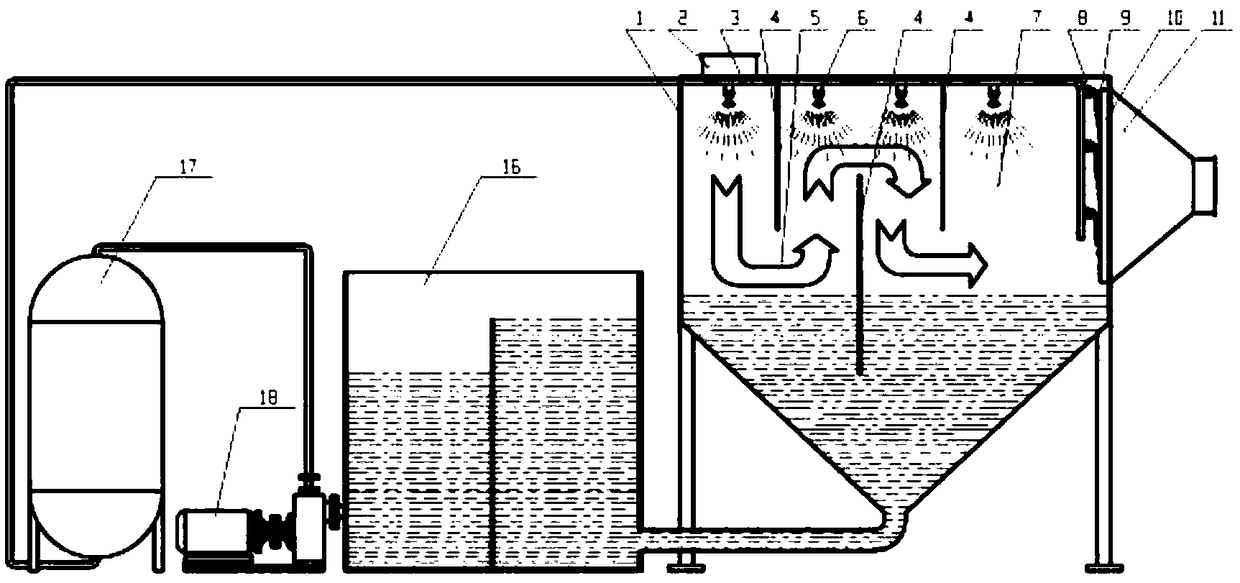

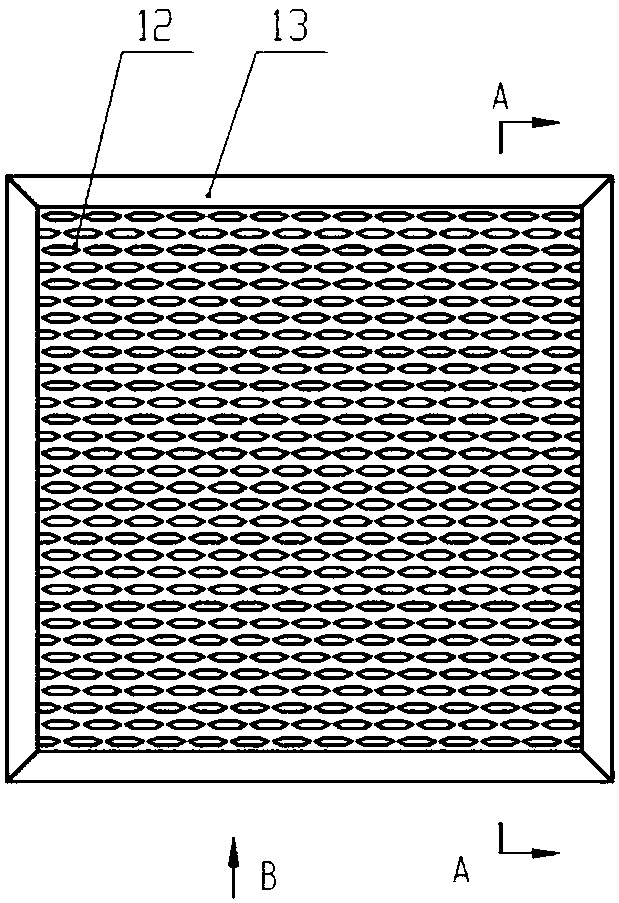

[0016] Such as Figure 1-Figure 4 As shown, the embodiment of the submicron water film dust collector of the present invention includes a dust removal chamber 1 and a partition 4 inside the chamber, thereby forming a primary filter dust removal chamber 5 and a fine filter dust removal chamber 7 . Inside the primary filter and dust removal cavity 5, there are pipelines 3 and round solid conical atomizing nozzles 6 arranged around the air inlet 2. In this embodiment, the nozzles are arranged in double rows, with 4 in each row, a total of 8 . The dust-laden gas entering the primary filter dust removal cavity 5 needs to go through two 180-degree turns and one 90-degree turn before reaching the fine filter cavity 7. During this process, the dust is caught by the mist droplets and becomes heavier and directly falls into the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com