Hot extrusion and near net forming method of asymmetric aluminum alloy flange plate with convex lug

A near-net shape and extrusion forming technology, which is applied in the direction of metal extrusion dies, metal processing equipment, transportation and packaging, etc., can solve the problems of low material utilization, poor mechanical properties of parts, long processing cycle, etc., and achieve shortened forming The effect of reducing the cycle time, reducing the amount of processing, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] The specific embodiment is carried out according to the following process steps:

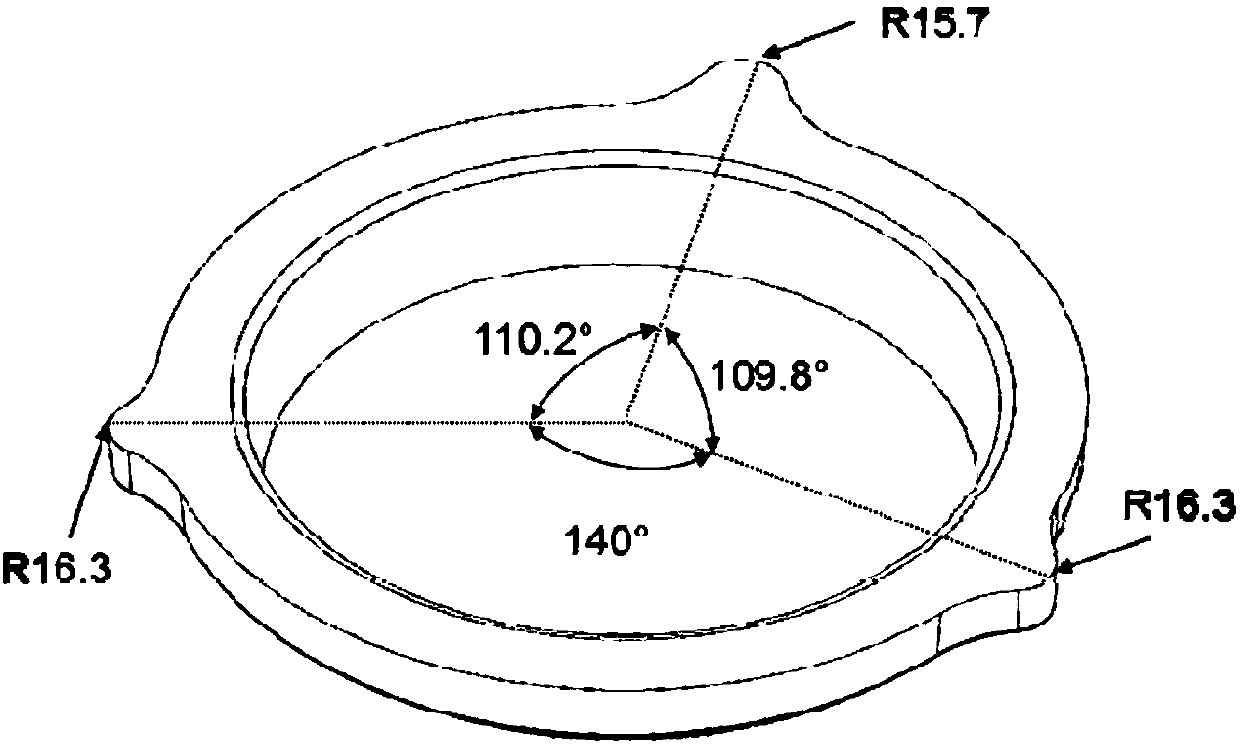

[0036] Step 1. Determine the basic extrusion parts: according to the parts diagram of the asymmetrical aluminum alloy flange with lugs that needs to be formed, convert it into a basic extrusion part. Leave a machining allowance of 5 mm on the surface, and consider the difficulty of demoulding. The extruded part is drawn, and the draft angle is 2°;

[0037] Step 2, calculation of the size of the hot extrusion billet: according to the principle of constant plastic deformation volume, the size of the cylindrical billet required for hot extrusion forming (ie is 200mm, h is 140mm), and processed out;

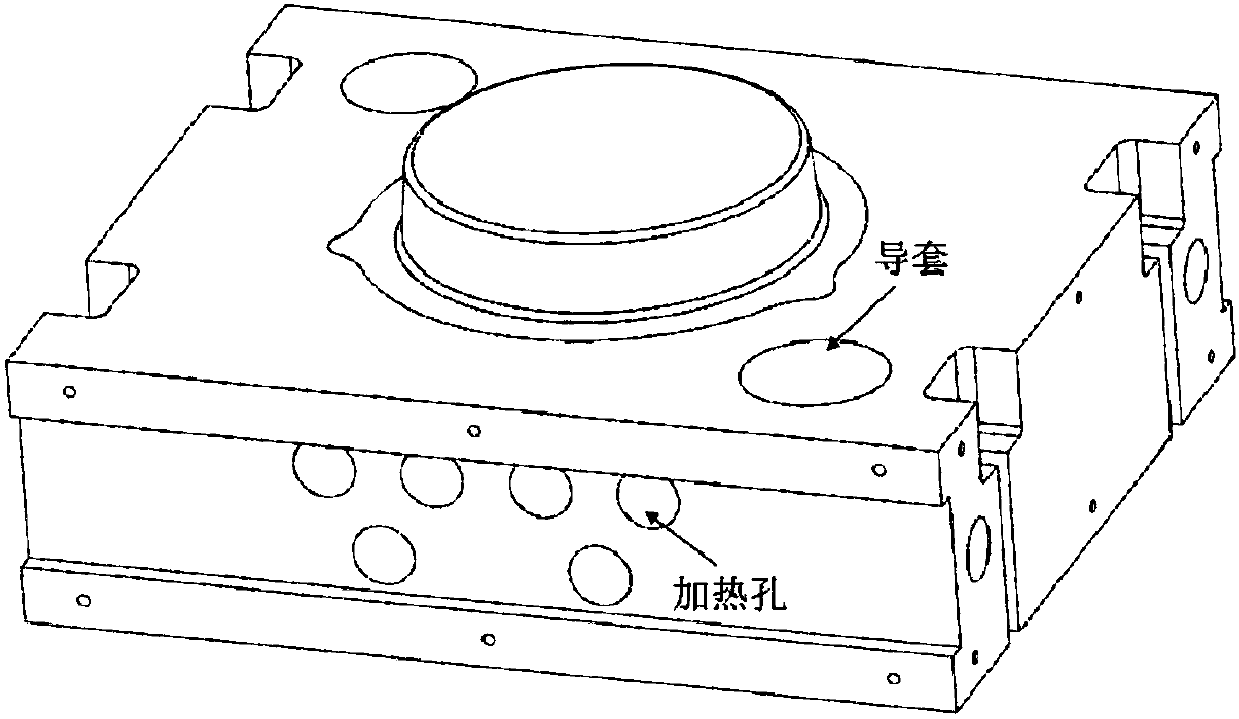

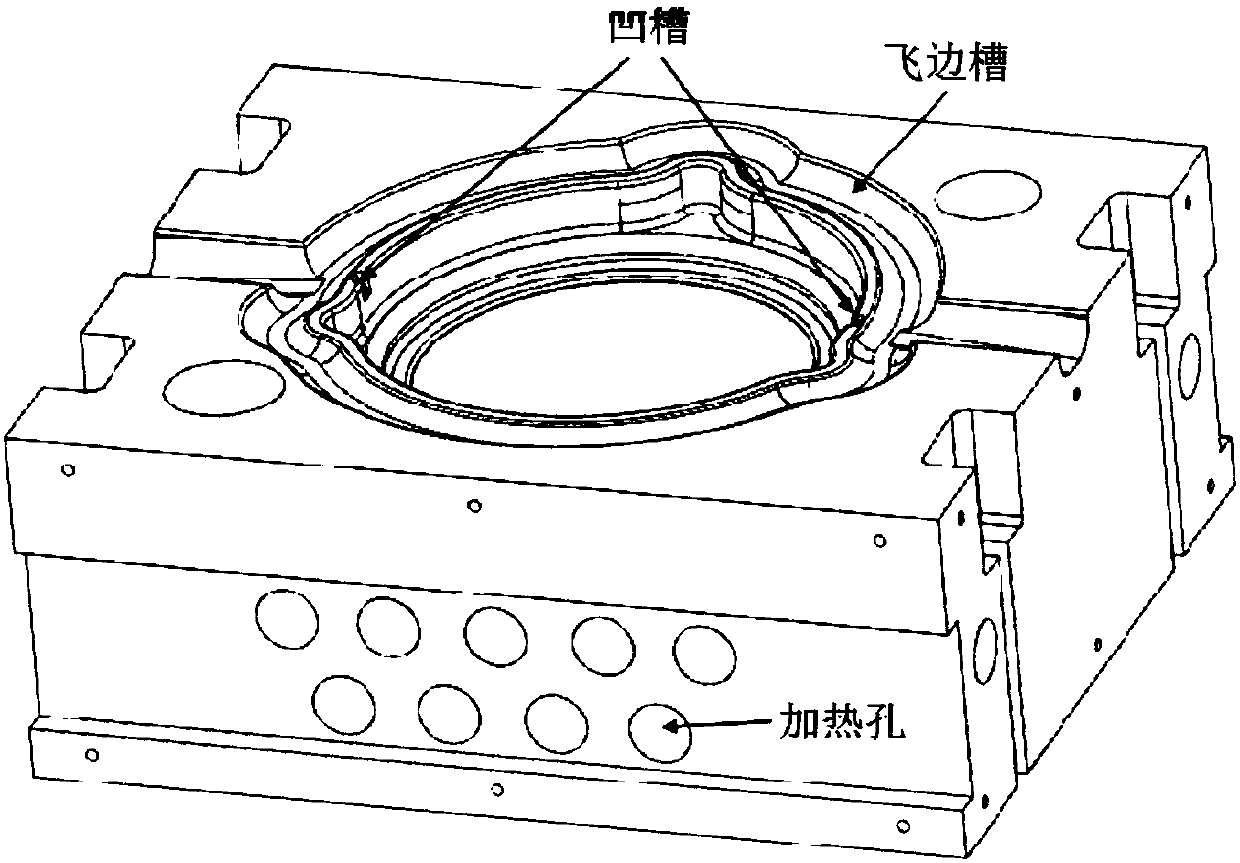

[0038] Step 3, designing a hot extrusion die: According to the flange extrusion obtained in Step 1, design and manufacture a hot extrusion die for an asymmetrical aluminum alloy flange with lugs. Extrusion dies include upper and lower dies, such as figure 2 , image 3 , Figure 4 As shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com