A preparation method of high-quality nitrogen-doped graphene quantum dots

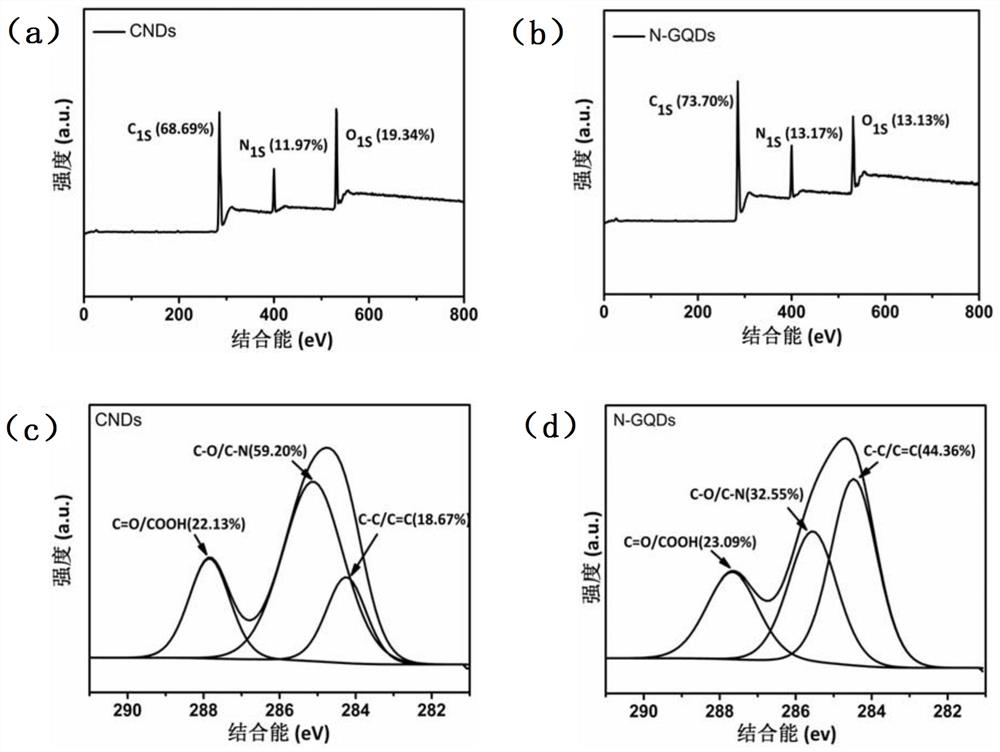

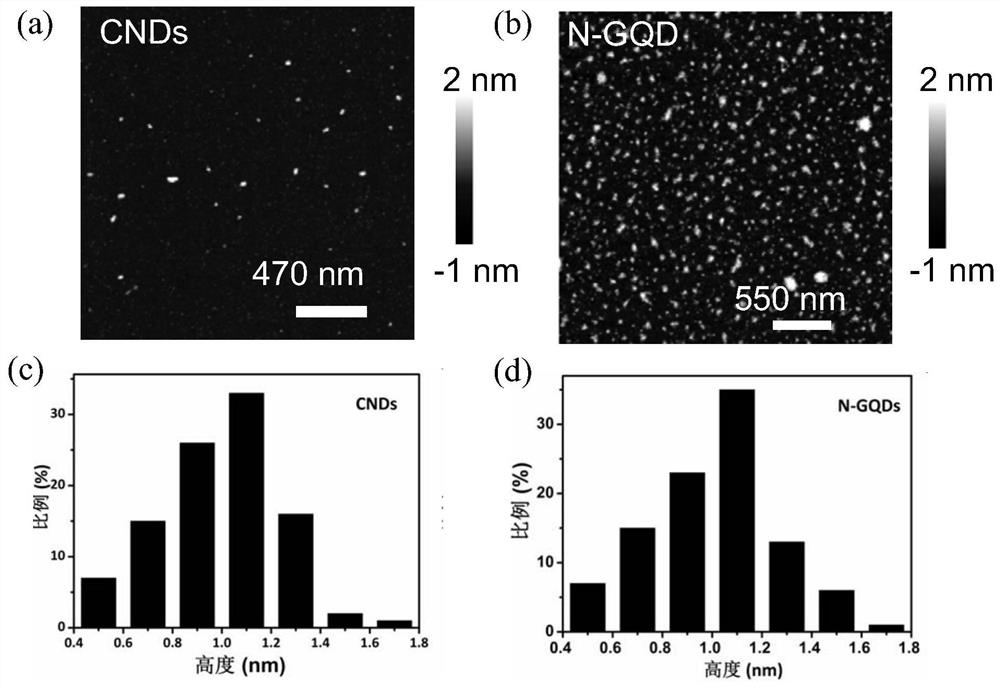

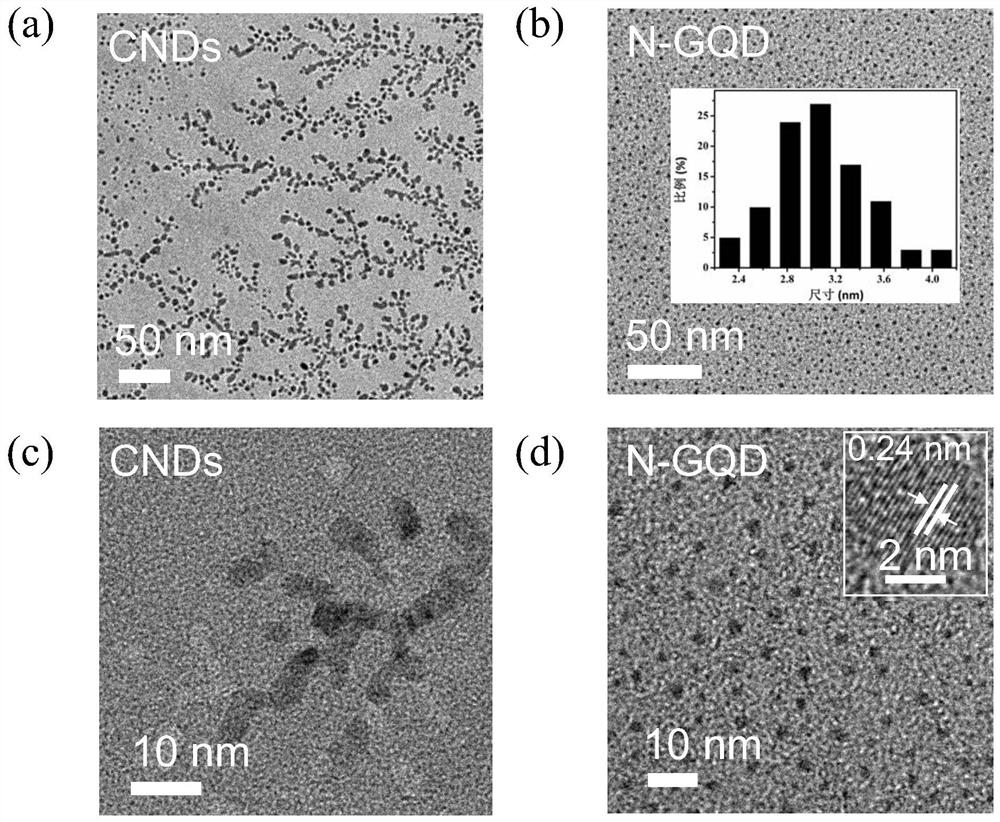

A graphene quantum dot and nitrogen doping technology, applied in the field of nanomaterials, can solve the problems of low carbonization degree and low carbon content graphene quantum dots, etc., and achieve the effects of high carbon content, good dispersibility, and high nitrogen content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of nitrogen-doped graphene quantum dots (NGQDs)

[0030] Weigh 1.345g (7mmol) of citric acid and 0.421g (7mmol) of ethylenediamine, add them to 70ml of ultrapure water, and then ultrasonicate for 10min at 200W to mix them evenly; transfer the ultrasonicated solution to 100ml of polytetrafluoroethylene In a vinyl fluoride reactor, react at 250°C for 6 hours to obtain a yellow-brown aqueous solution; take the solution and evaporate it under reduced pressure at 50°C to dryness to obtain a solid powder of nitrogen-doped graphene quantum dot "intermediate" . Weigh 0.2g of the "intermediate" of nitrogen-doped graphene quantum dots and add it to 70ml of N,N-dimethylformamide (DMF) and ultrasonically mix it uniformly under 200W for 10min; the solution after ultrasonic Transfer to a 100ml polytetrafluoroethylene reactor, and react at 250°C for 12 hours to obtain a brown DMF solution; finally, filter the DMF solution to remove large-sized products, and ...

Embodiment 2

[0040] Weigh 4.035g (21mmol) of citric acid and 0.421g (7mmol) of ethylenediamine, add them to 70ml of ultrapure water, and then ultrasonicate for 10min at 200W to mix them evenly; transfer the ultrasonicated solution to 100ml of polytetrafluoroethylene In a vinyl fluoride reactor, react at 180°C for 12 hours to obtain a yellow-brown aqueous solution; take the solution and evaporate it under reduced pressure at 50°C to dryness to obtain a solid powder of nitrogen-doped graphene quantum dot "intermediate" . Weigh 1.0g of the "intermediate" of nitrogen-doped graphene quantum dots and add it to 70ml of N,N-dimethylformamide, and then sonicate it for 10min at 200W to mix it evenly; transfer the sonicated solution to 100ml In a polytetrafluoroethylene reactor, react at 150°C for 6 hours to obtain a brown DMF solution; finally filter the DMF solution to remove large-sized products, and dialyze the filtrate in water to remove unreacted The complete "intermediate" as well as DMF, yie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com