Nitrogen and sulfur codoped porous carbon material and preparation and application methods thereof

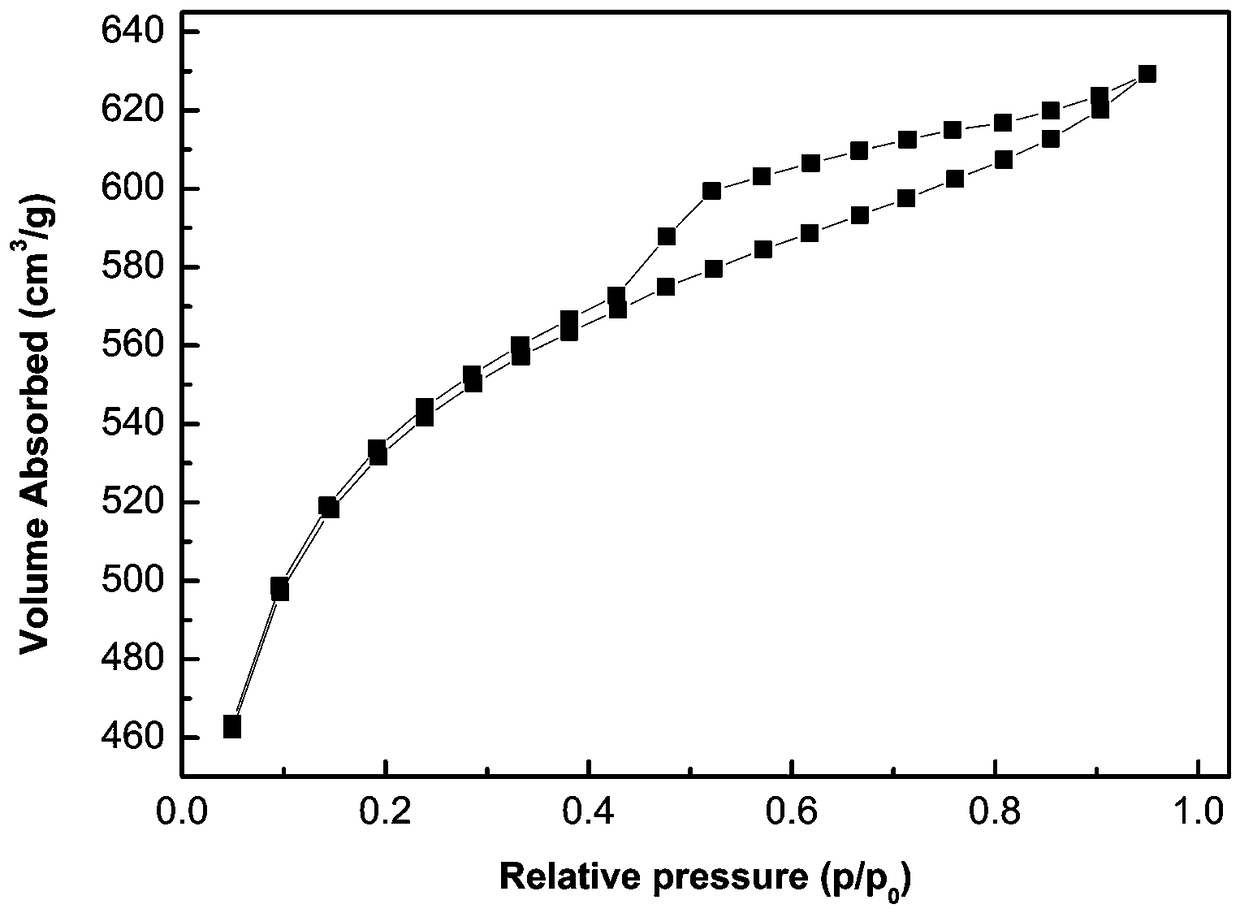

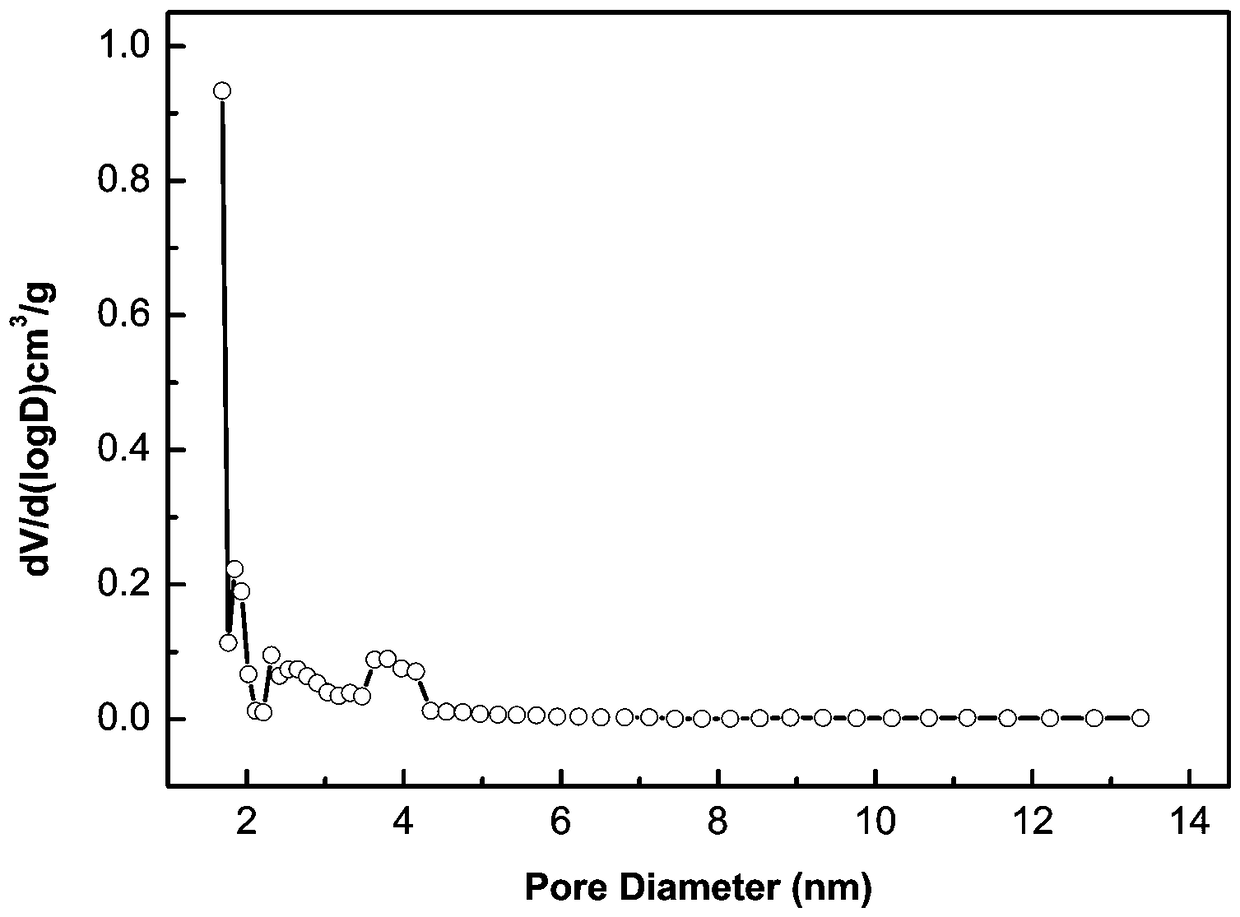

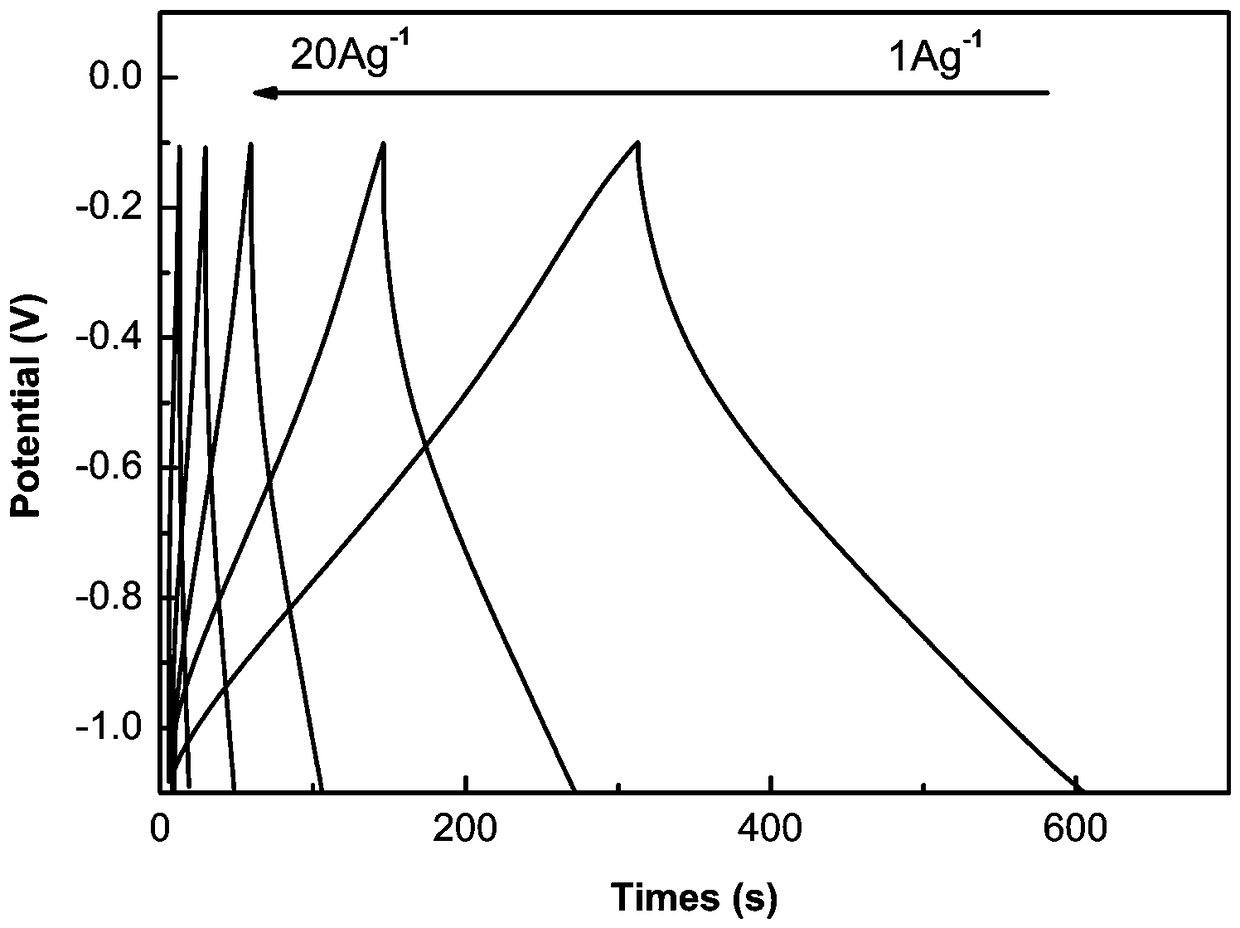

A porous carbon material, nitrogen and sulfur co-doping technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of small specific surface area, low specific capacitance, low nitrogen content, etc., to achieve large specific surface area, The effect of high specific capacitance and controllable nitrogen and sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The preparation method of nitrogen-sulfur co-doped porous carbon material is as follows:

[0039] Step 1) Protonation treatment of melamine, put melamine in a muffle furnace at 250 °C, carbonize at a low temperature for 4 hours, dissolve the carbonized product in concentrated sulfuric acid and stir for 4 hours, then dilute, filter, wash until neutral, and dry to obtain Protonated melamine;

[0040] Step 2) Preparation of nitrogen- and sulfur-containing precursors. Protonated melamine, glucose, and dimethyl sulfoxide were added to deionized water at a ratio of 1:4:2 for ultrasonic dispersion, stirred and dissolved, and then at 180 °C, After reacting for 6 h, the product was filtered, washed, and dried to obtain a nitrogen-containing sulfur precursor;

[0041] Step 3) Activation of nitrogen- and sulfur-containing precursors. Mix the nitrogen- and sulfur-containing precursors and the basic inorganic substance KOH at a ratio of 1.0:2.0, stir and soak in deionized water, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com