Calcium zirconate material doped with metal and preparation method and application of calcium zirconate material

A calcium zirconate, metal technology, applied in electrochemical variables of materials, chemical instruments and methods, fuel cells, etc., can solve the problems of high price, poor mechanical properties and stability, and high cost, and achieve low cost, physical properties and chemical properties. Stable performance and less pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing a metal-doped calcium zirconate material, which specifically includes the following steps:

[0028] S1, calcium carbonate (CaCO 3 ) powder, zirconia (ZrO 2 ) powder and chromium oxide (Cr 2 o 3 ) powder in molar ratio, CaCO 3 :ZrO 2 :Cr 2 o 3 =1:0.7:0.15 for batching. Among them, CaCO 3 The analytical purity of the powder is 99%, ZrO 2 The powder is analytically pure with a purity of 99%, Cr 2 o 3 The analytical purity of the powder was 99.9%.

[0029] S2. Mix all the powders obtained in step S1 together and put them into an agate mortar for grinding for 2.5 hours to form the first material to be molded. The particle size of the first molded material is ≤80 μm.

[0030] Specifically, using an agate mortar for grinding has simple operation and low cost, and avoids the need to add some reagents when grinding in other ways, which may lead to the introduction of impurities or increase the experiment time. Mixing a...

Embodiment 2

[0049] This embodiment provides a method for preparing a metal-doped calcium zirconate material, which specifically includes the following steps:

[0050] S1, calcium carbonate (CaCO 3 ) powder, zirconia (ZrO 2 ) powder and chromium oxide (Cr 2 o 3 ) powder in molar ratio, CaCO 3 :ZrO 2 :Cr 2 o 3 =1:0.9:0.05 for batching. Among them, CaCO 3 The analytical purity of the powder is 99%, ZrO 2 The powder is analytically pure with a purity of 99%, Cr 2 o 3 The analytical purity of the powder was 99.9%.

[0051] S2. Mix all the powders obtained in step S1 and put them into an agate mortar for grinding. The grinding time is 2 hours to form the first material to be molded. The particle size of the first material to be molded is ≤80 μm.

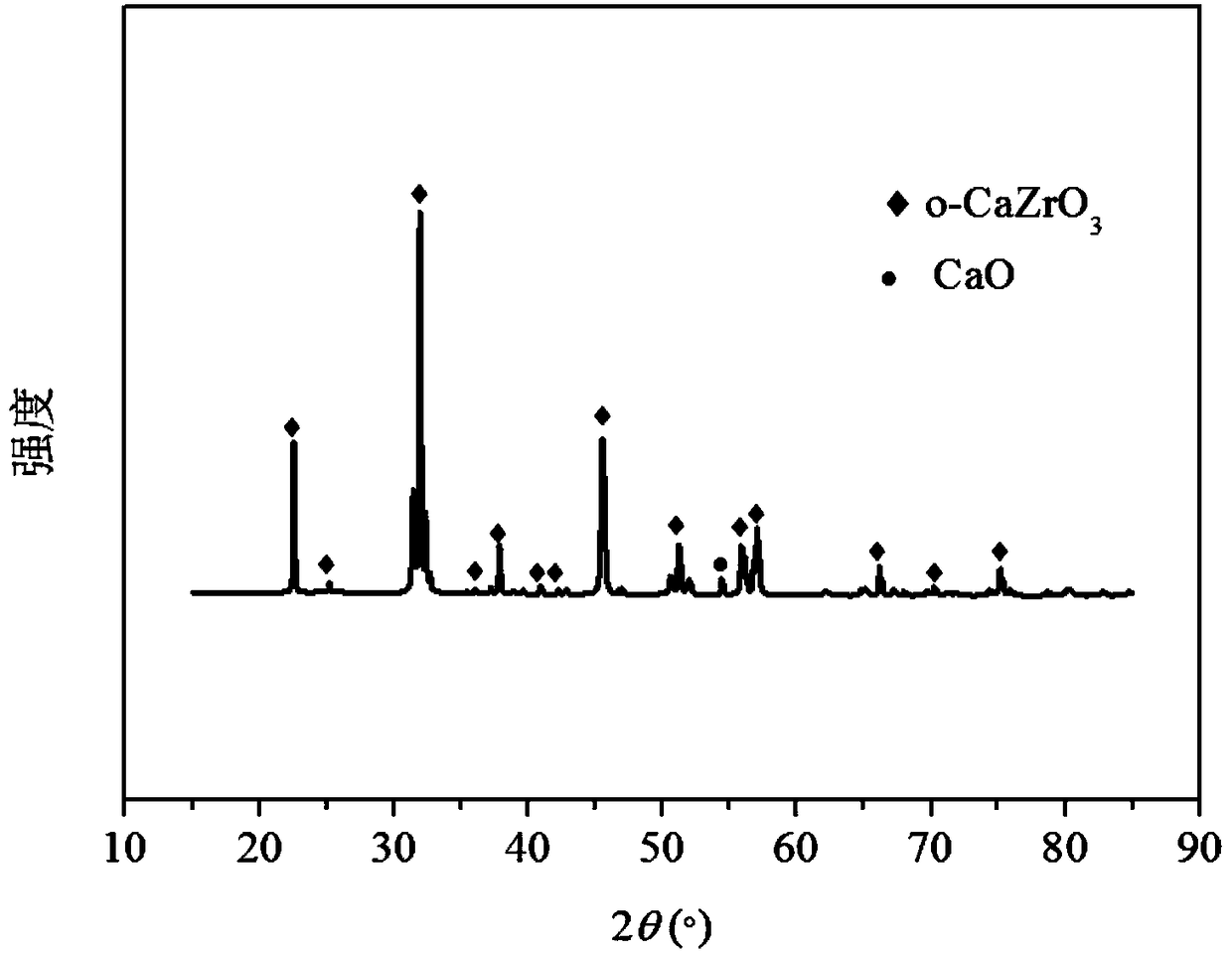

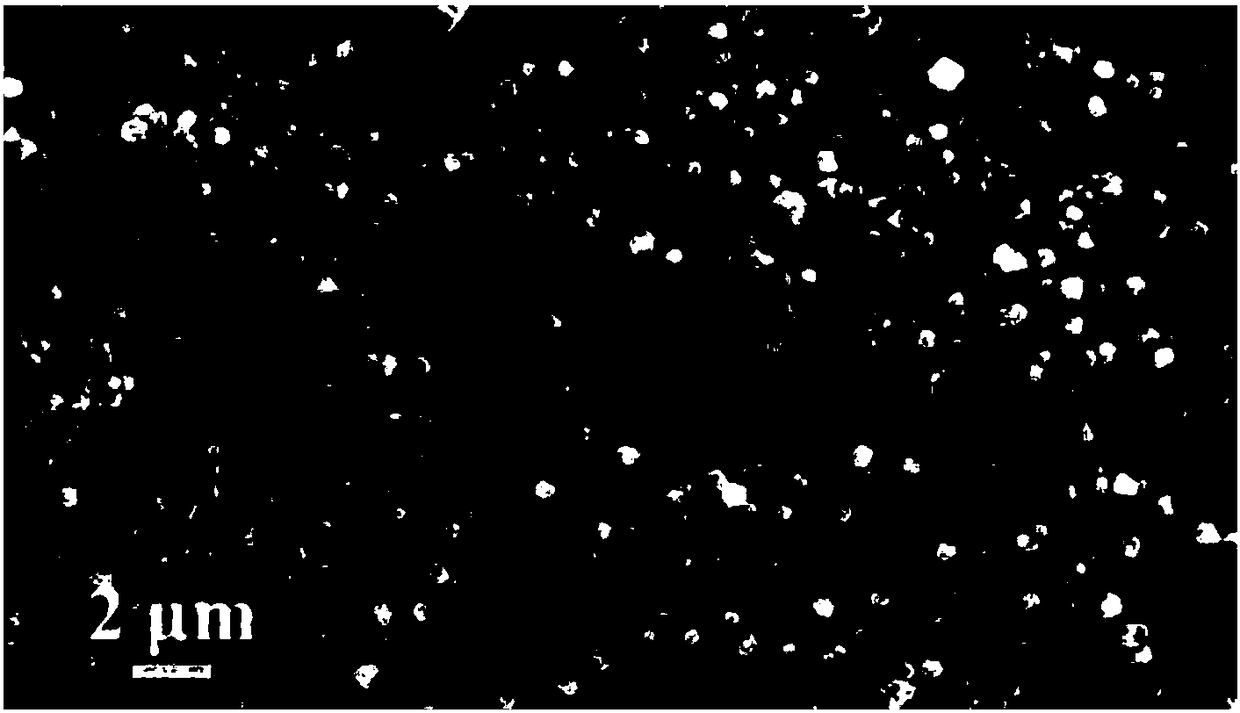

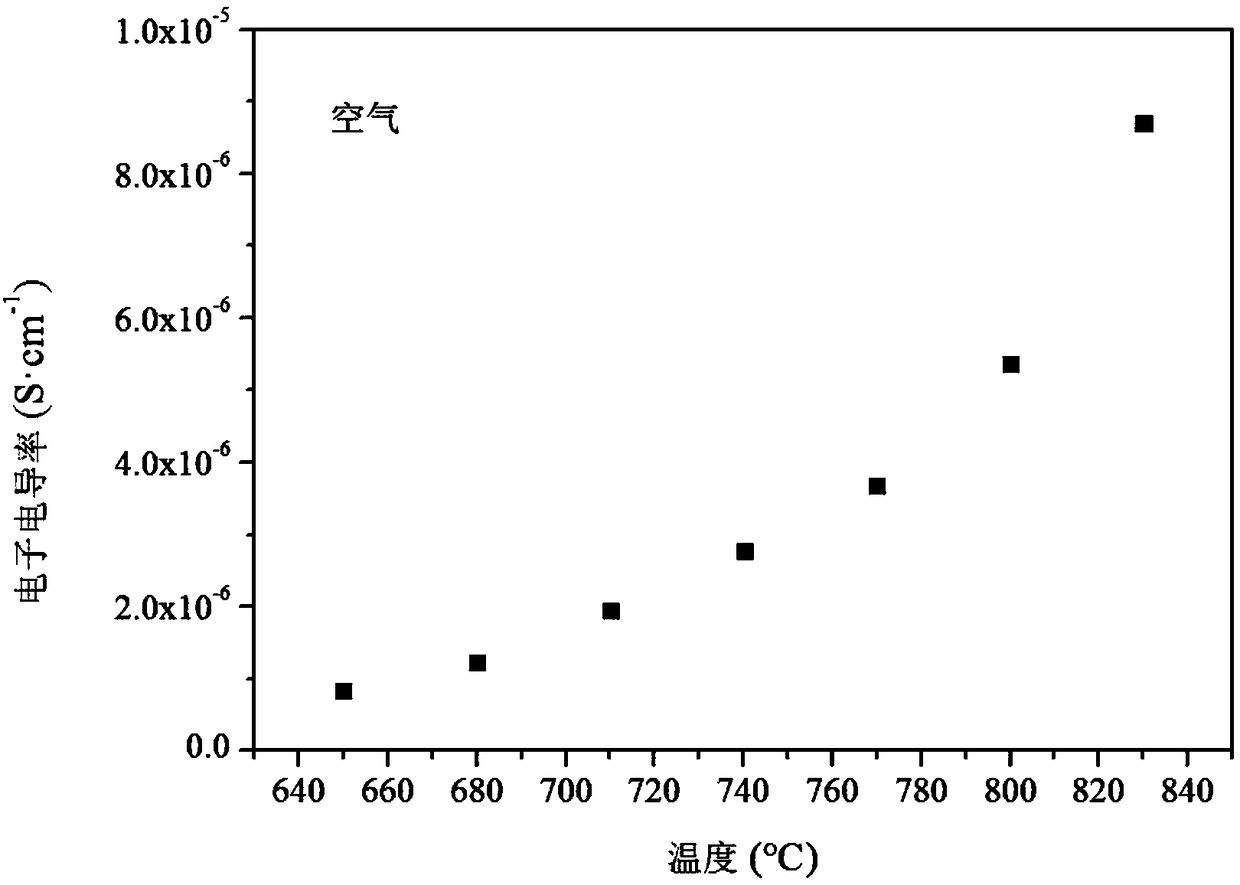

[0052] S3. Compress the first material to be molded under a compression pressure of 6.5 MPa by cold pressing, and then perform calcination at 1200° C. for 8 hours to obtain a chromium-doped calcium zirconate composite. The composition of ...

Embodiment 3

[0059] This embodiment provides a method for preparing a metal-doped calcium zirconate material, which specifically includes the following steps:

[0060] S1, calcium carbonate (CaCO 3 ) powder, zirconia (ZrO 2 ) powder and chromium oxide (Cr 2 o 3 ) powder in molar ratio, CaCO 3 :ZrO 2 :Cr 2 o 3 =1:0.8:0.1 for batching. Among them, CaCO 3 The analytical purity of the powder is 99%, ZrO 2 The powder is analytically pure with a purity of 99%, Cr 2 o 3 The analytical purity of the powder was 99.9%.

[0061] S2. Mix all the powders obtained in step S1 together and put them into an agate mortar for grinding for 3 hours to form the first material to be molded. The particle size of the first molded material is ≤80 μm.

[0062] S3. Compress the first material to be molded under a compression pressure of 12 MPa by cold pressing, and then perform calcination at 1300° C. for 5 hours to obtain a chromium-doped calcium zirconate composite. The composition of the obtained comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com