Combined test device and method for treating wastewater by means of hot-air concentration-flash evaporation

A technology for treating waste water and hot air, which is applied in the direction of heating water/sewage treatment, special treatment targets, water/sewage treatment, etc. It can solve the problems of pipeline scaling, high operating cost of evaporation technology, blockage, etc. The effect of simple, simple test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

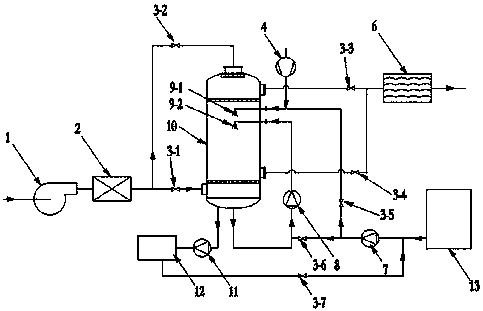

[0035] Such as figure 1 Shown is a schematic diagram of a device for treating waste water using hot air concentration-flash evaporation provided in this embodiment, including a fan 1, an air heater 2, a demister 6, a water supply pump 7, a concentrated flash tank 10, an outlet pump 11, a collection Tank 12 and raw water buffer tank 13, wherein fan 1 is connected to air heater 2, and air heater 2 is connected to concentrated flash tank 10, and the air outlet of concentrated flash tank 10 is connected to demister 6; The outlet is connected to the collection tank 12 through the outlet pump 11; the collection tank 12 is connected to the water supply pump 7; the raw water buffer tank 13 is connected to the water supply pump 7; the water supply pump 7 is connected to the liquid inlet of the concentrated flash tank 10 through a pipeline.

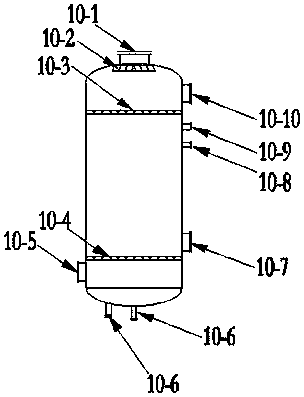

[0036] figure 2 As shown, it is a schematic diagram of the concentration flash tank, including the first air inlet 10-1 arranged on the top of t...

Embodiment 2

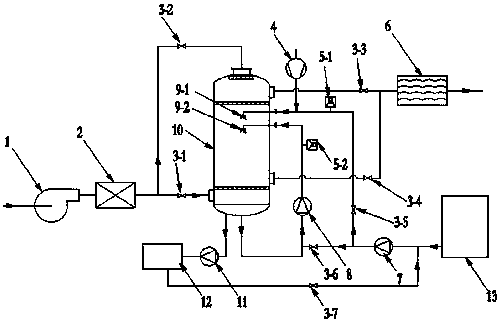

[0038] Embodiment 2 This embodiment is a further improvement on the basis of Embodiment 1, wherein as image 3 As shown, the fifth pipeline is provided with a first sonic descaler 5-1, and the sixth pipeline is provided with a second sonic descaler 5-2, as Figure 4 As shown, the first air distributor 10-3 and the second air distributor 10-4 are gas distribution plates with uniformly arranged holes.

[0039] The method of using the hot air concentration-flashing device for treating wastewater provided by this embodiment to carry out concentration and flash treatment specifically includes the following steps:

[0040] Step 1, waste water concentration: The waste water is transported to the sonic single-phase flow atomization nozzle under the action of the circulating pump and atomized into small droplets in the concentration flash tank, and the air at normal temperature and pressure enters the air heater under the action of the fan. Internally heated to high-temperature and hi...

Embodiment 3

[0043] Utilize the device that utilizes hot air concentration-flashing treatment waste water provided by the present invention to carry out the method for concentration and flash treatment, the specific process is as follows:

[0044] Wastewater concentration: the high-salt wastewater in the raw water buffer tank enters the circulation pipeline through the pipeline connected with the sixth valve under the delivery of the water supply pump, and enters the sonic single-phase flow atomization nozzle under the operation of the circulation pump, and the liquid is atomized into Small droplets, the liquid particle size is 200μm-2000μm. The air at normal temperature and pressure enters the air heater under the conveyance of the fan and becomes high-temperature hot air. The temperature of the hot air is 80-110°C. The high-temperature gas enters the concentrated flash tank through the second air inlet through the pipeline connected with the first valve. The liquid droplets contact and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com