Device and method for enhancing sludge dewatering by means of periodic reversal electrocoagulation

A technology of sludge dehydration and electrocoagulation, applied in electrochemical sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as increased energy consumption, low hydraulic permeability coefficient, and reduced reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

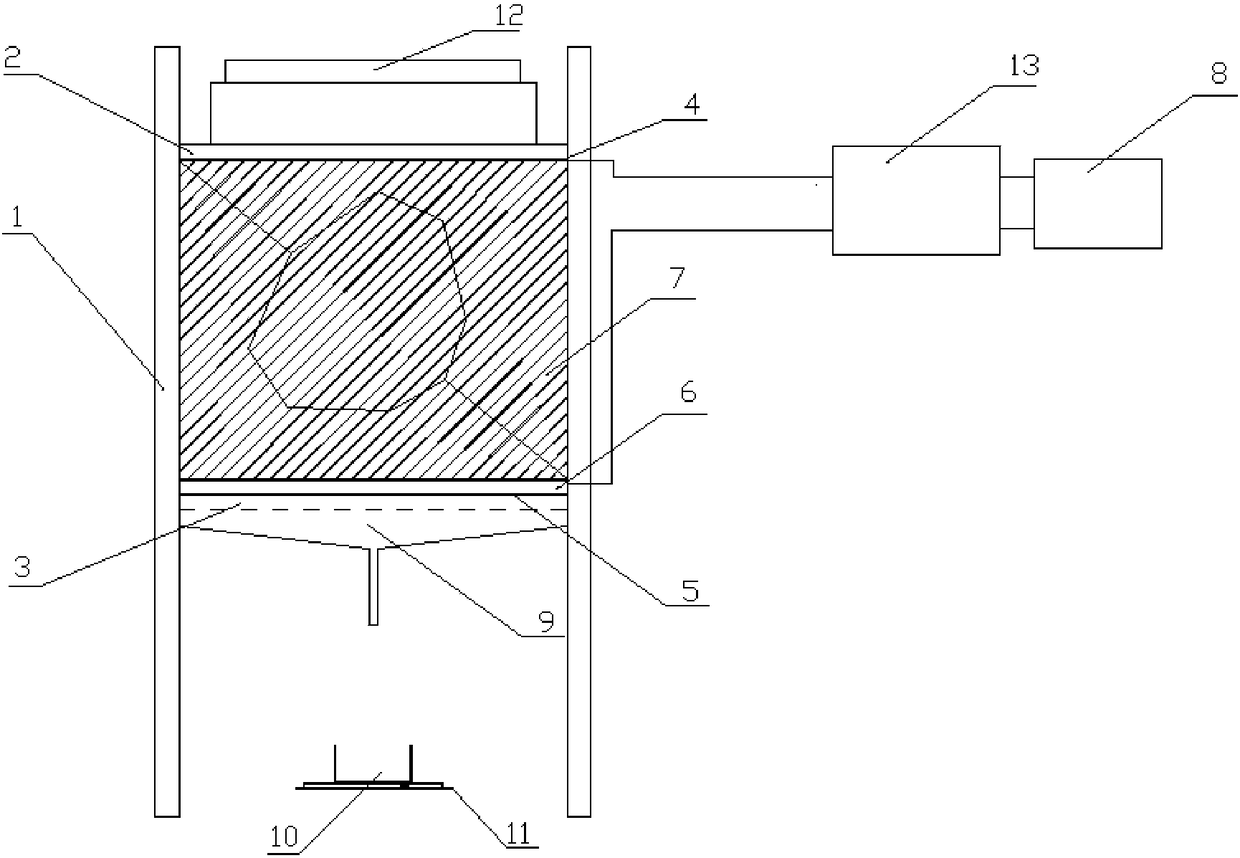

[0040] Such as figure 1 As shown, the periodic reversing electrocoagulation enhanced sludge dewatering device, the main body of the device is a cylinder 1, the cylinder 1 is a machine glass cylinder, and the upper end of the cylinder 1 is provided with a movable piston along its longitudinal axis 2. The lower part of the piston 2 is a flat iron electrode 4 fixed by bolts. The lower end of the cylinder body 1 is fixed with a wire mesh electrode 6, and the wire mesh electrode 6 is lined with a PET filter cloth 5 (commercially purchased, aperture 0.8 mm) to discharge the removed water, and the bottom of the PET filter cloth 5 is a porous organic glass plate body 3 (The material is methyl methacrylate, the aperture is 5 mm, and the porosity is 11.11%). The wire mesh electrode 6 and the porous organic glass plate body 3 jointly fix the PET filter cloth 5 . The side wall of the piston 2 is slidably connected with the inner wall of the cylinder 1, the side of the flat iron electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com