Asphalt mixture stirring equipment and technology for adding reclaimed materials in high proportions

A technology of asphalt mixture and mixing equipment, which is applied in the field of asphalt mixture mixing equipment with a high proportion of recycled materials, which can solve the problems of limiting the percentage of recycled materials, and achieve the effects of reducing energy loss, precise temperature control, and high heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

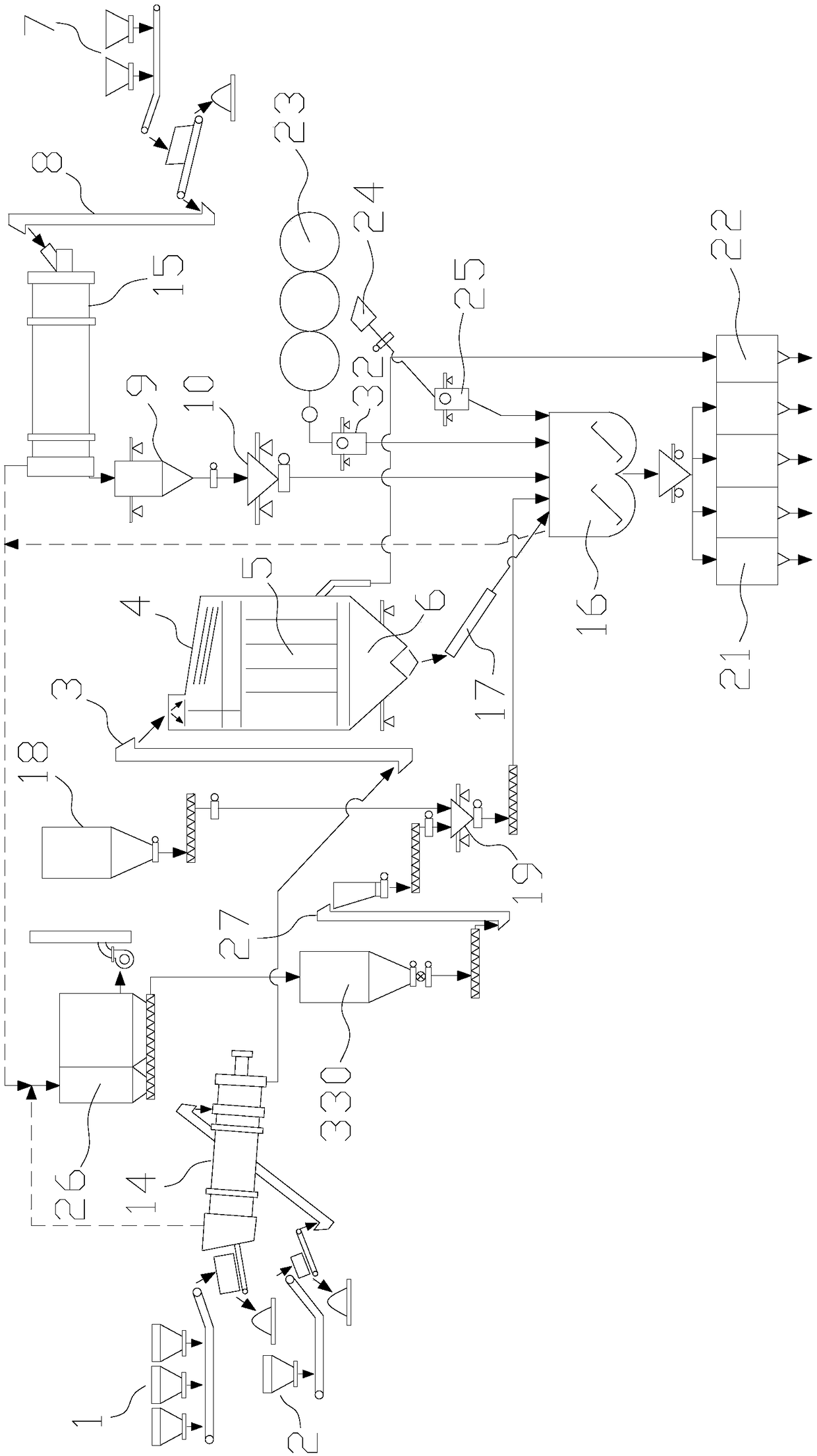

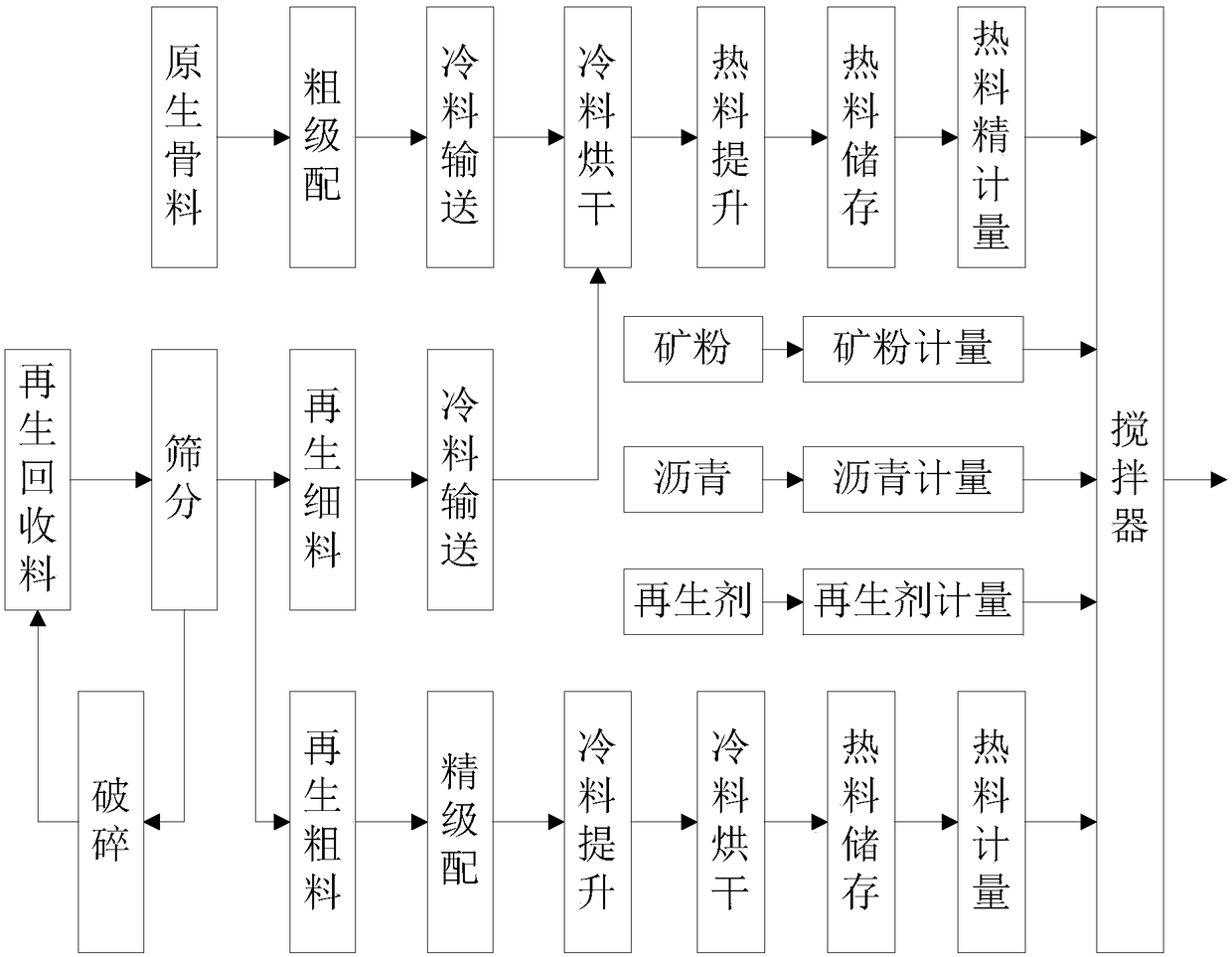

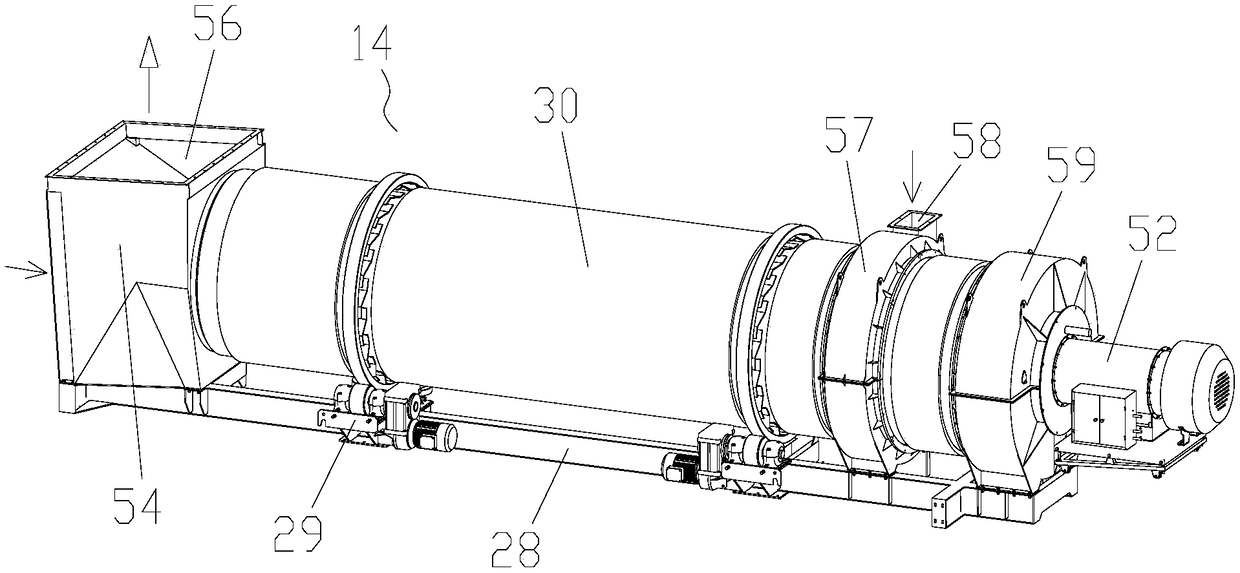

[0043] Such as figure 1 As shown, a kind of asphalt mixing equipment with high proportion of recycled materials added, including primary aggregate supply device 1, recycled fine material supply device 2, recycled mixture drying drum 14, hot material elevator 3, hot aggregate vibrating screen Extension 4, hot aggregate temporary storage bin 5, hot aggregate weighing bin 6, recycled rough material supply device 7, cold material hoist 8, recycled coarse material drying drum 15, recycled hot material temporary storage bin 9, recycled hot material metering The bin 10 and the agitator 16, the regenerated coarse material drying drum 15, the regenerated hot material temporary storage bin 9, the regenerated hot material metering bin 10 and the agitator 16 are vertic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com