Method and system for increasing energy storage efficiency of compressed air by using ORC

A compressed air energy storage and high-pressure air technology, which is applied in steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as unsuitable applications, constraints, and low energy storage efficiency, so as to avoid heat loss, increase power generation, and Effect of Energy Storage Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments will be described in detail below in conjunction with the accompanying drawings.

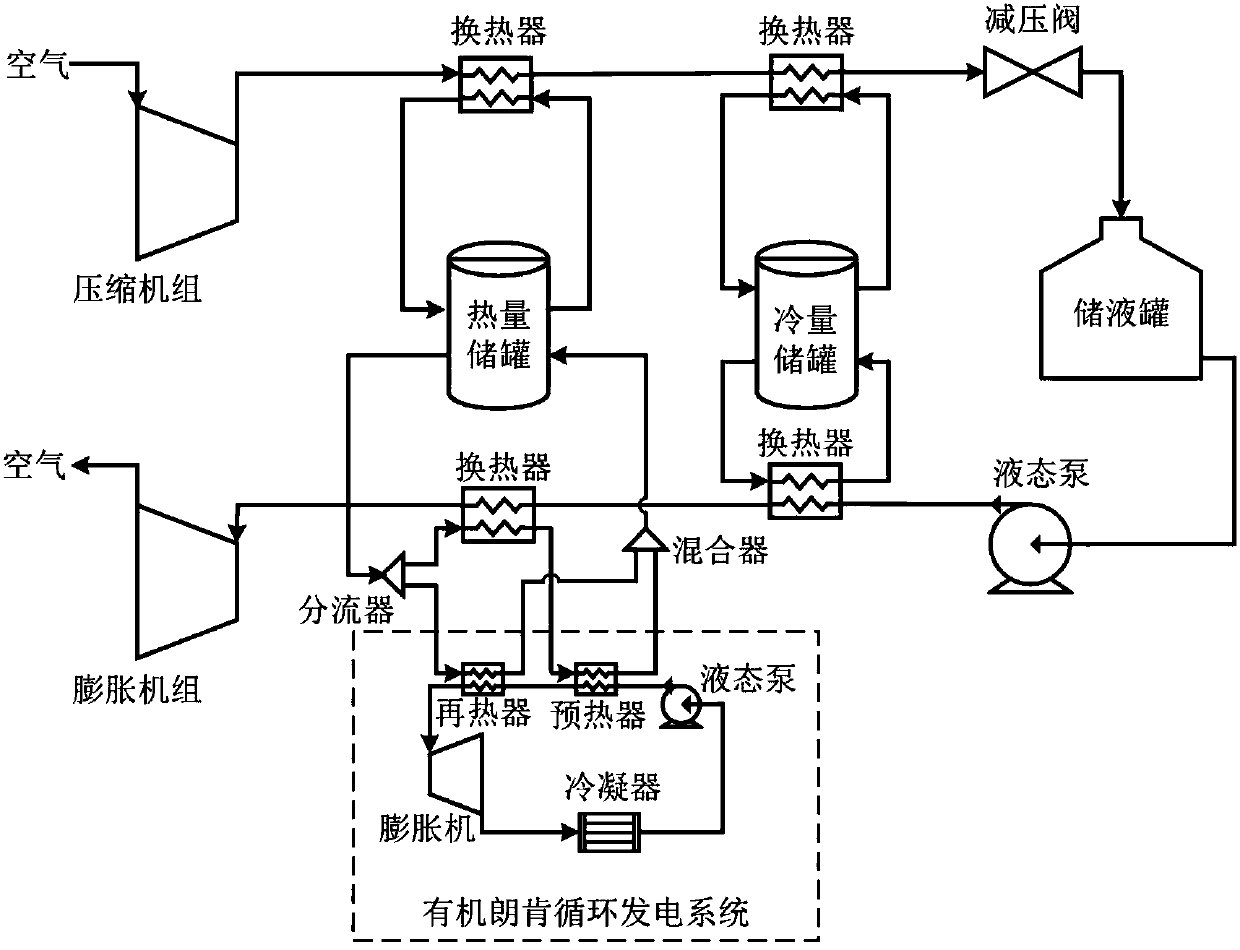

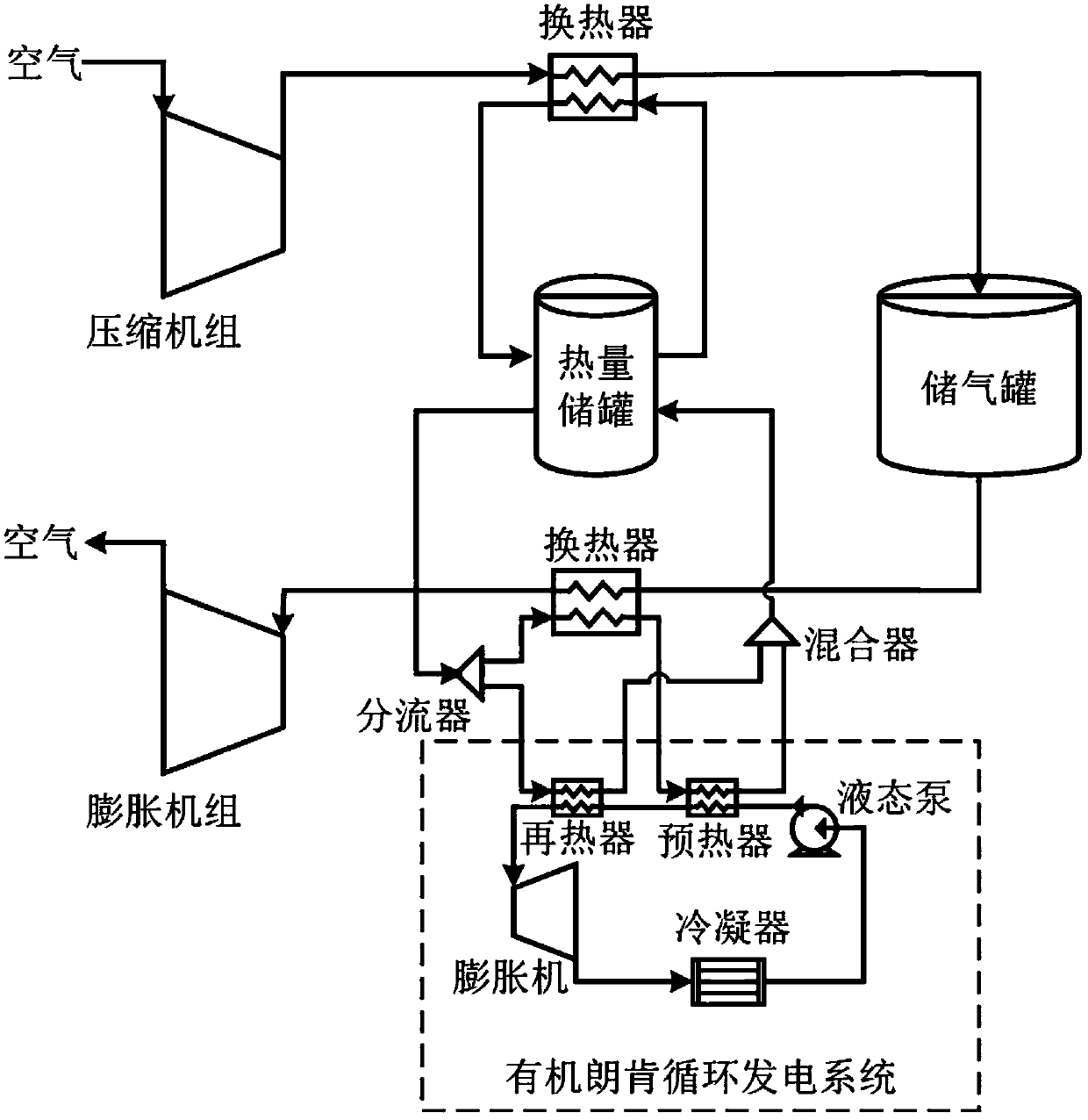

[0024] The present invention is a method for improving the efficiency of the compressed air energy storage system by coupling the ORC system with the CAES system. figure 1 It is the LAES system diagram of the coupling ORC of the present invention, figure 2 It is the AA-CAES system diagram coupled with ORC of the present invention. The method is described by taking the LAES system as an example, but the method is also applicable to the AA-CAES system.

[0025] By establishing the thermodynamic model of the LAES system, in the process of energy storage, the air is compressed and the compression heat is stored in the heat storage tank; in the process of energy release, the heat in the heat storage tank is used to heat the high-pressure air, and the heated Air enters the expander and expands to do work. Through calculation, it is found that when the air flow in the energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com