flywheel engine

A technology for engines and flywheels, which is applied to combustion engines, engine components, flywheels, etc., can solve the problems of large fuel adaptability, many moving parts, and small adaptability, and achieve large fuel adaptability, low speed requirements, and easy maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

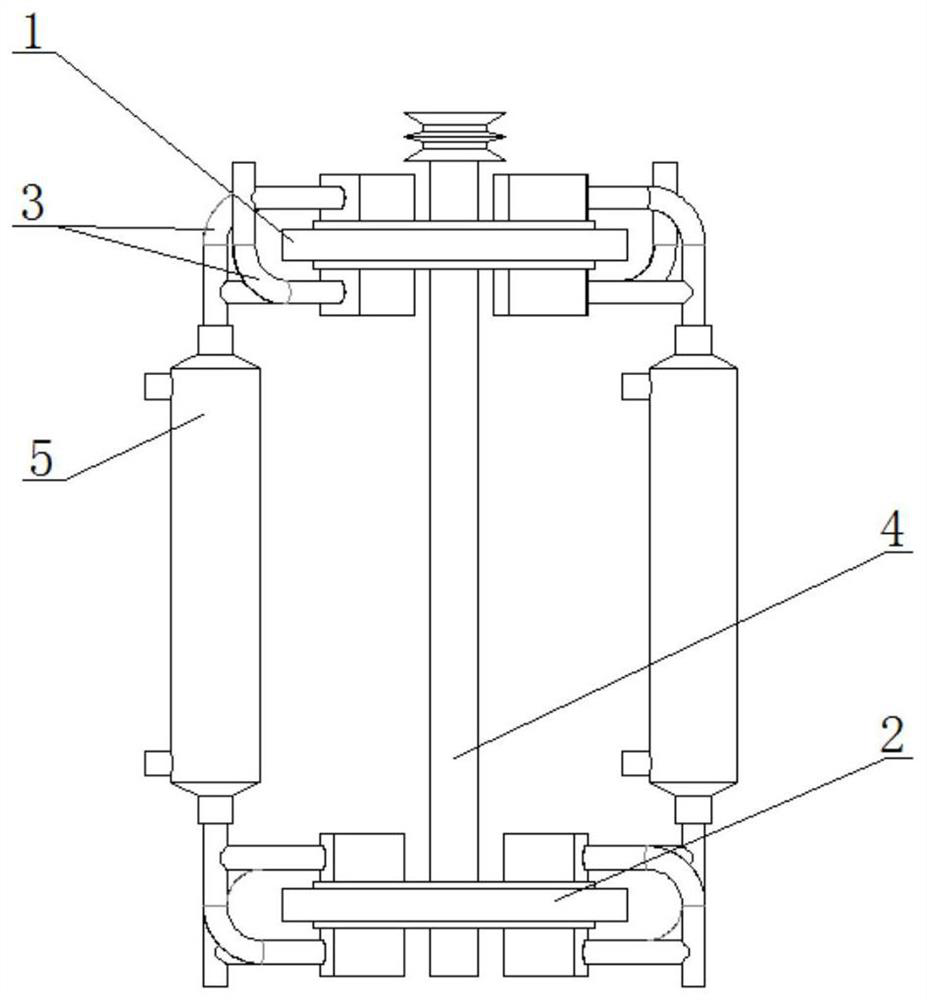

[0035]A kind of flywheel engine of the present invention, it comprises working chamber 1, suction chamber 2, air duct 3, central axis 4, and each said working chamber and suction chamber are respectively made of flywheel 100, flywheel housing 101, flywheel cover 102, gas brush 103 composition;

[0036] The flywheel engine of the present embodiment installs two flywheels to form a double-wheel mode, see figure 2 , the flywheel engine has a work chamber and a suction chamber, the flywheel engine also includes a combustion heating chamber 5, and the outlet end of the suction chamber is also provided with a valve for preventing the working fluid from flowing back into the suction chamber from the heating pipe One-way air valve, the working chamber, the suction chamber, and the combustion heating chamber are connected through an air guide tube. The two flywheels in this embodiment are respectively arranged in the working chamber and the suction chamber, and the working chamber has...

Embodiment 2

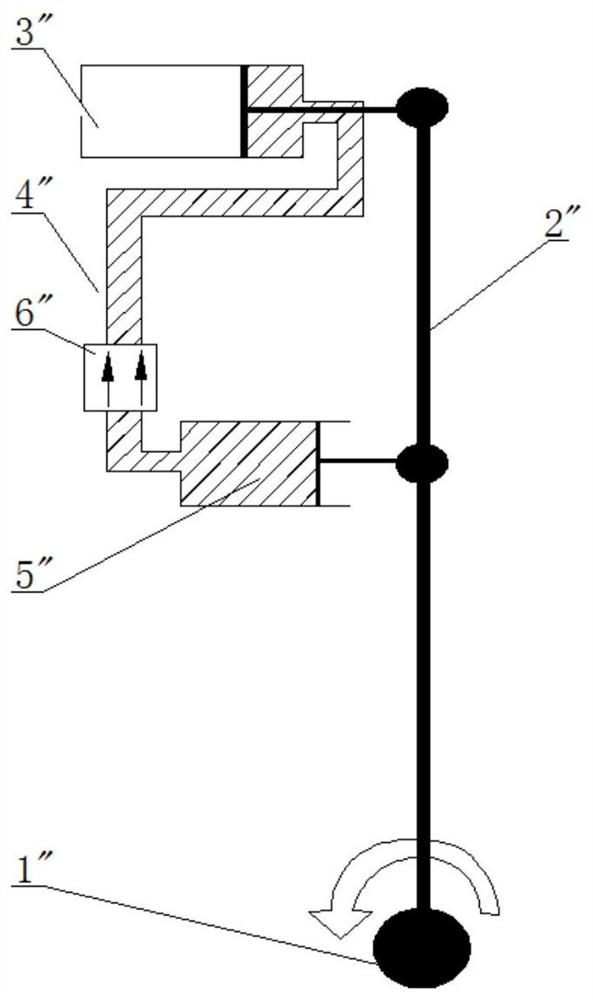

[0042] The flywheel engine of the present embodiment is a double-cycle mode under the double-wheel mode, a kind of flywheel engine, it comprises working chamber, suction chamber, air duct, center shaft, each described working chamber and suction chamber are respectively composed of flywheel, Composed of flywheel housing, flywheel cover and air brush;

[0043] The flywheel cover is a disc body, the disc body includes a circular ring, and a bearing hole for the central shaft to pass through the middle, the flywheel is a double-wheel mode, and the upper left side of the flywheel cover has a One air intake hole, one air outlet hole on the upper right side, one air outlet hole on the lower left side, and one air inlet hole on the lower right side, and the flywheel cover also has two air brush installation holes;

[0044] The air outlet hole is connected with an air outlet pipe, the air inlet hole is connected with an air inlet pipe, and the flywheel cover is also provided with a sh...

Embodiment 3

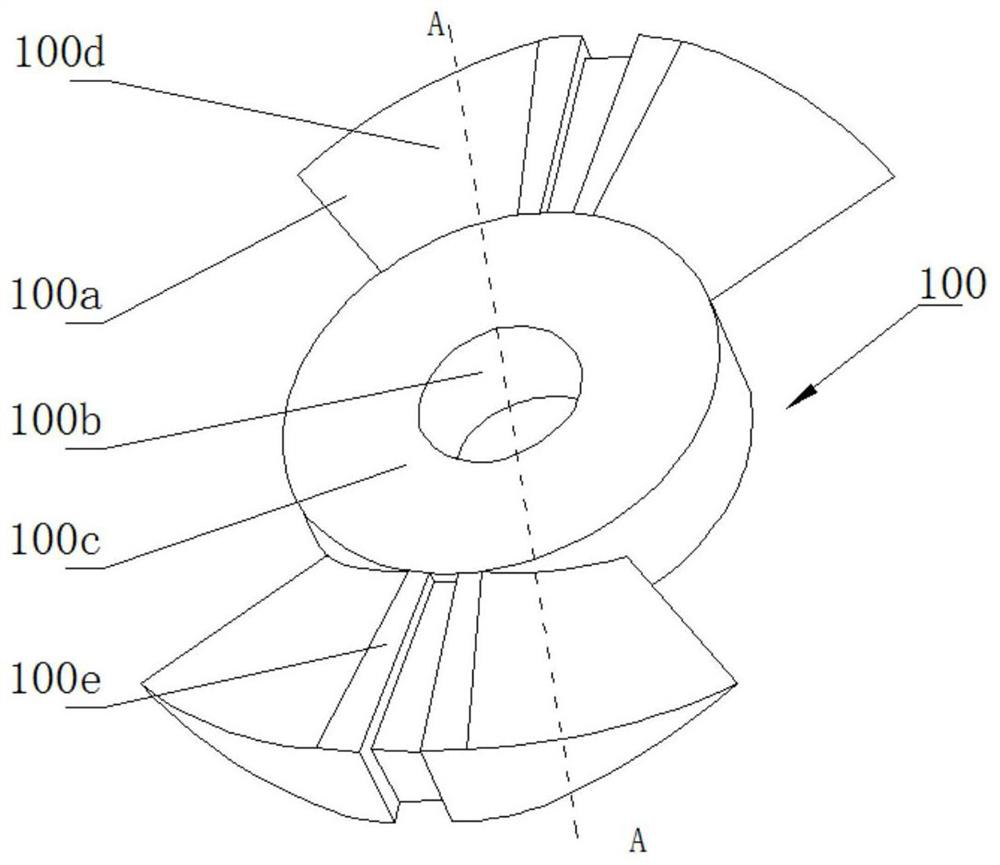

[0050] The flywheel engine of the present embodiment adopts a single wheel mode, and it comprises a work chamber, an air suction chamber, an air duct, a combustion heating chamber, and a central axis, and each said work chamber and air suction chamber are respectively composed of a flywheel 200, a flywheel housing, and a flywheel cover. 201. The composition of the air brush, the structure of the flywheel 200 and the flywheel cover 201 in the single-wheel mode refer to Figure 11 , Figure 12 ; The flywheel is placed in the middle of the flywheel shell, and the two flywheel covers are closed on the left and right sides of the flywheel, and the central shaft passes through the bearing hole of the flywheel cover and is fixed in the flywheel shaft hole.

[0051] The flywheel 200 is a circular wheel structure, and the circular wheel structure includes a first circular wheel sector 200a, a second circular wheel sector 200b, an axle hole 200c for fixing the center shaft, and spokes f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com