Online metering and automatic conveying and distribution system of setting machine auxiliary and control method

A technology of machine additives and sizing machines, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc. It can solve the problems of untimely dosing of sizing machine additives, low efficiency of quality traceability, and inaccurate control of measurement, etc. problem, to achieve the effect of large storage volume of raw materials for sizing machine additives, improvement of product competitiveness, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

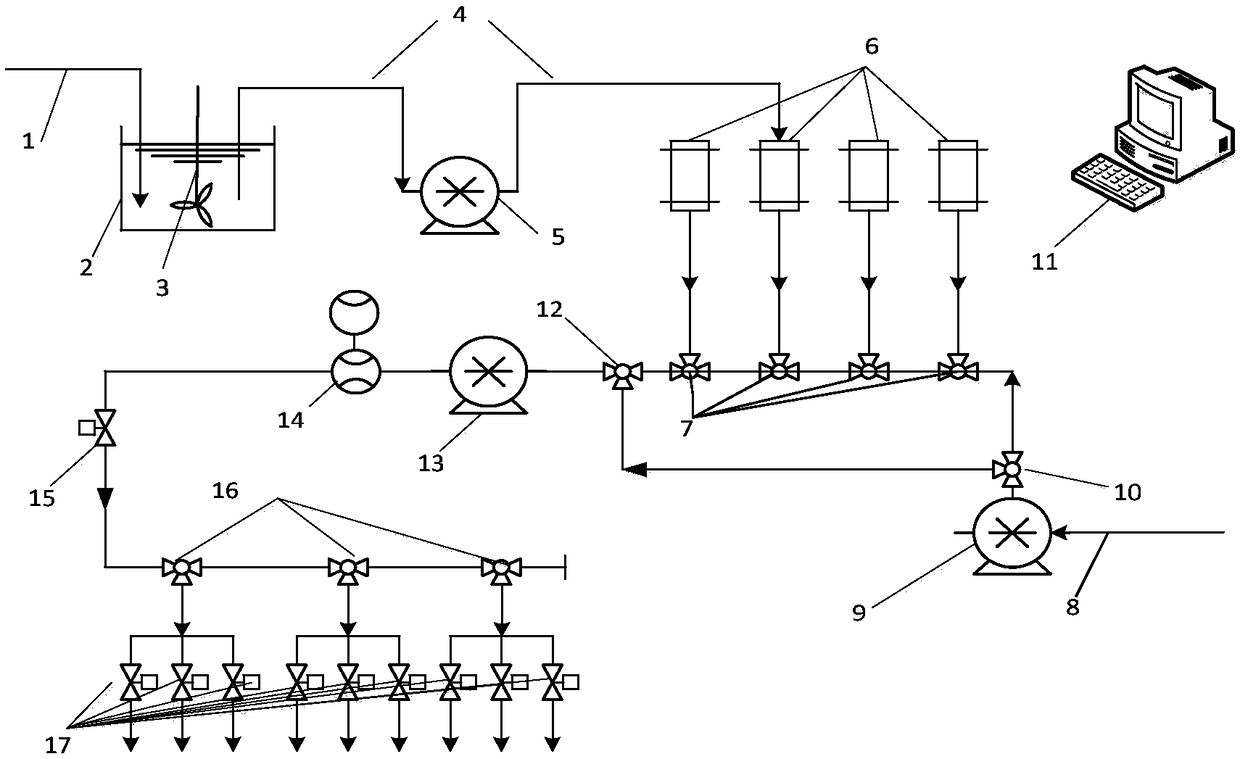

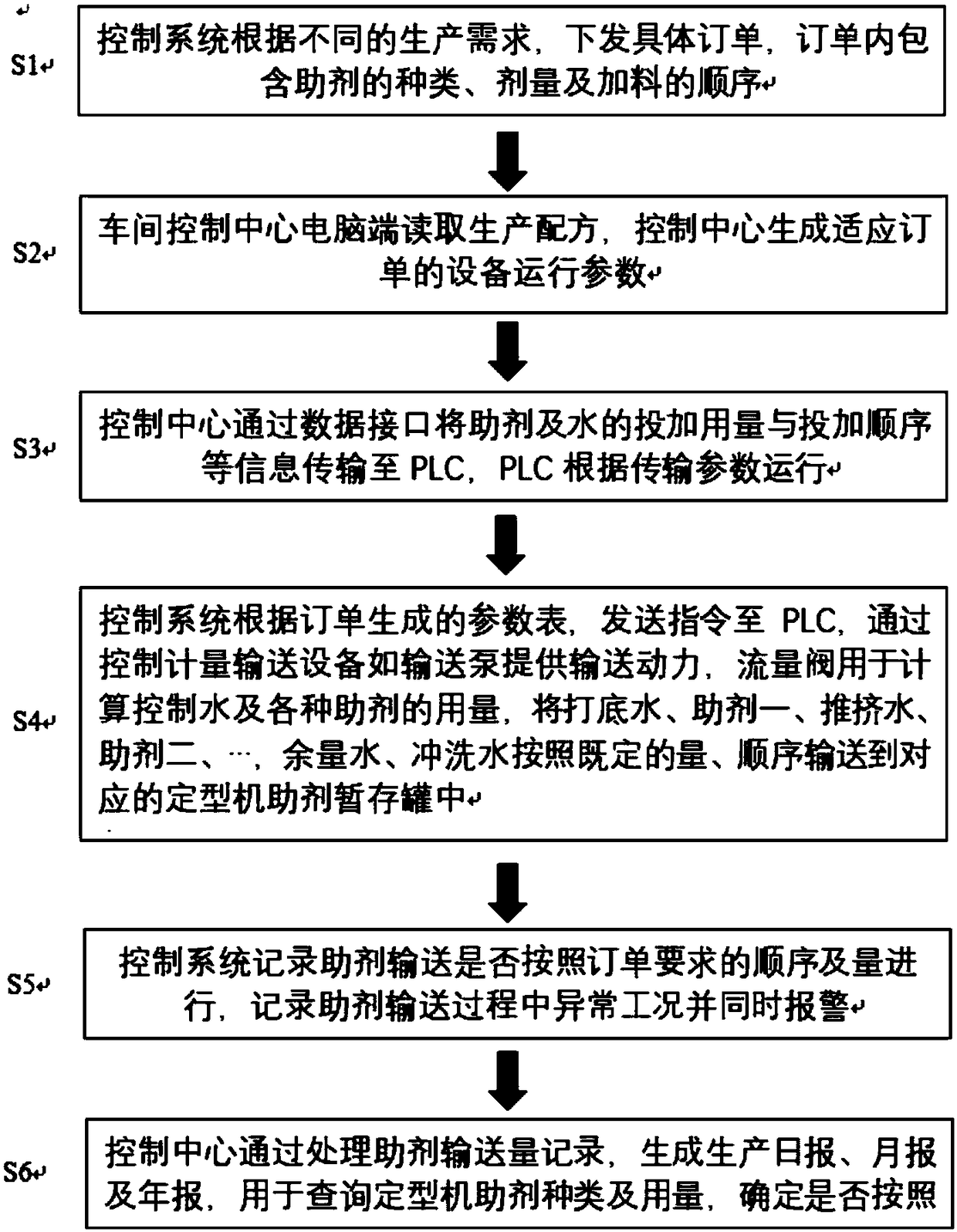

[0030] The on-line metering and automatic delivery and distribution system of auxiliary agents for a sizing machine in this embodiment includes a diluting storage system for auxiliaries for a sizing machine, an automatic metering and distribution control system for auxiliaries for a sizing machine, a workshop distribution system for auxiliaries for a sizing machine, and a control system; Styling machine auxiliary agent diluting storage system is used to realize the sizing machine auxiliary agent dilution storage process section; the sizing machine auxiliary agent automatic metering and distribution system part is used to realize the sizing machine auxiliary agent distribution, metering and conveying process section; the workshop The part of the distribution system is used to realize the distribution of the auxiliary agent of the sizing machine among the different sizing machines in the workshop; the control system is used to realize the manual control and automatic program opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com