Reactor pit direct retention type reactor core melt capturing device

A core melt and reactor technology, which is applied in the field of nuclear safety control, can solve the problems that the core trap needs a large expansion chamber, the cooling effect of the core melt is poor, and the migration path of the core melt is long. Reduced risk of steam explosion, avoids remelting, ease of construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

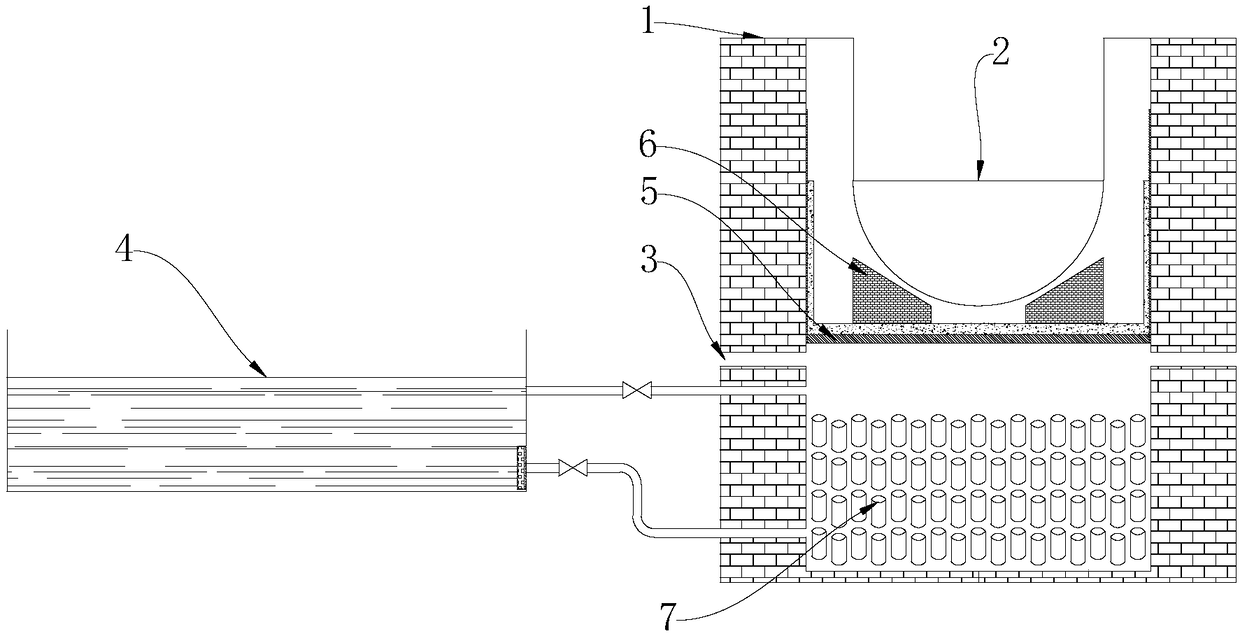

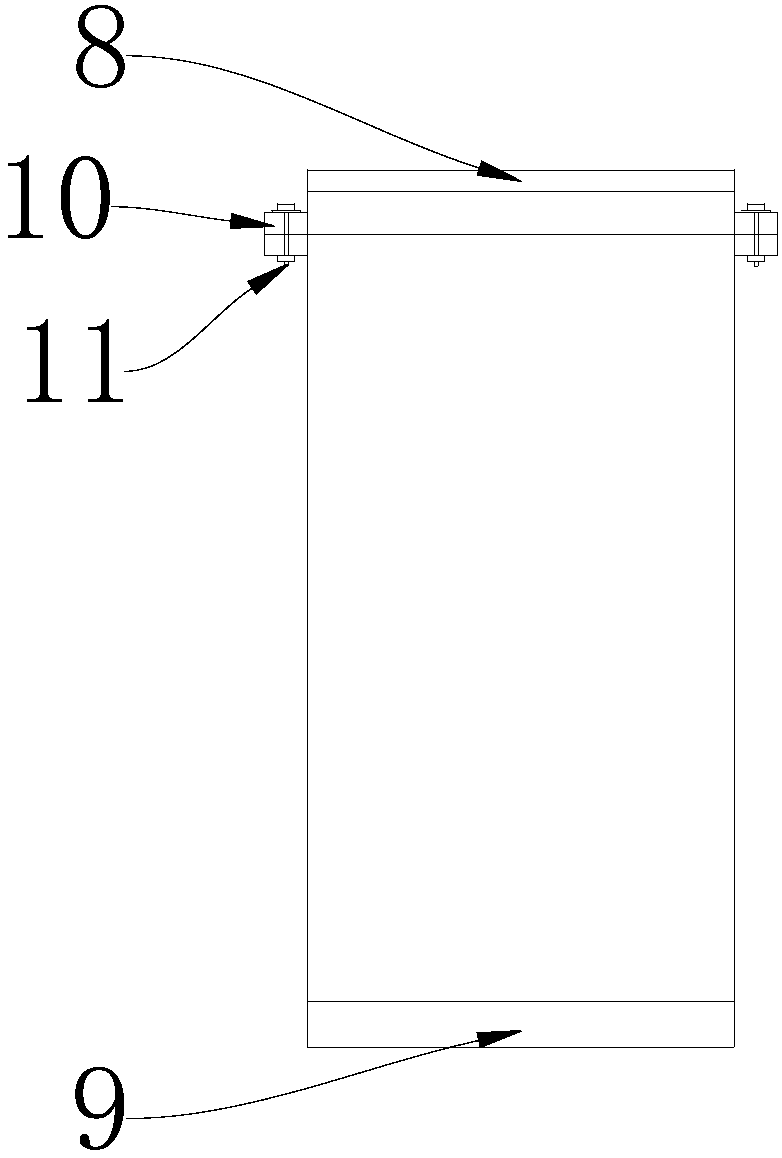

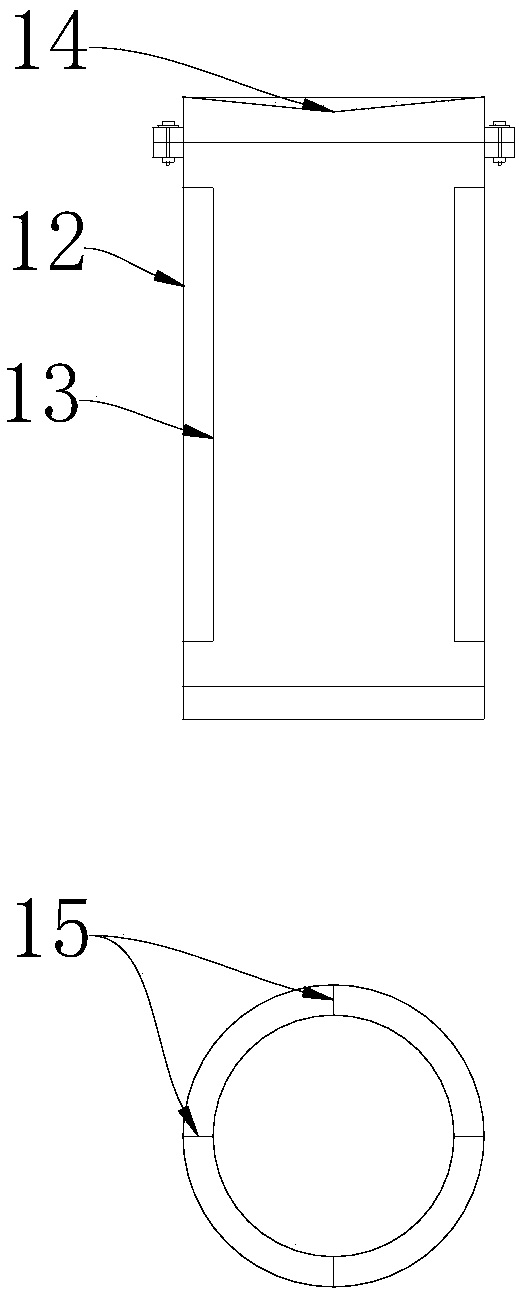

[0058] The composition and structure of the reactor core molten material capture device of the exemplary reactor pit direct retention of the present invention is as follows: Figure 1-4 As shown, it includes a reactor pit 1, a reactor pressure vessel 2, a steam discharge port 3, a cooling water tank 4, an inspection platform 5, a shock absorbing device 6, and a metal sealed tank 7.

[0059] The maintenance platform 5 is placed in the pit pile 1 and divides the pit pile 1 into upper and lower halves. The maintenance platform 5 is spliced by glass plates with high mechanical strength (the glass plates have a structure of 2-4 layers, which are bonded with glass glue, and the thickness of each tempered glass plate is 10-15mm, and the load-bearing per unit area is not less than 1700kg). , and a layer of sacrificial concrete with a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com