Secondary battery with lithium supplement electrode and preparation method thereof

A technology for secondary batteries and lithium supplementation, which is applied in the manufacture of secondary batteries, electrolyte batteries, non-aqueous electrolyte batteries, etc., and can solve the problems of low first cycle and cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

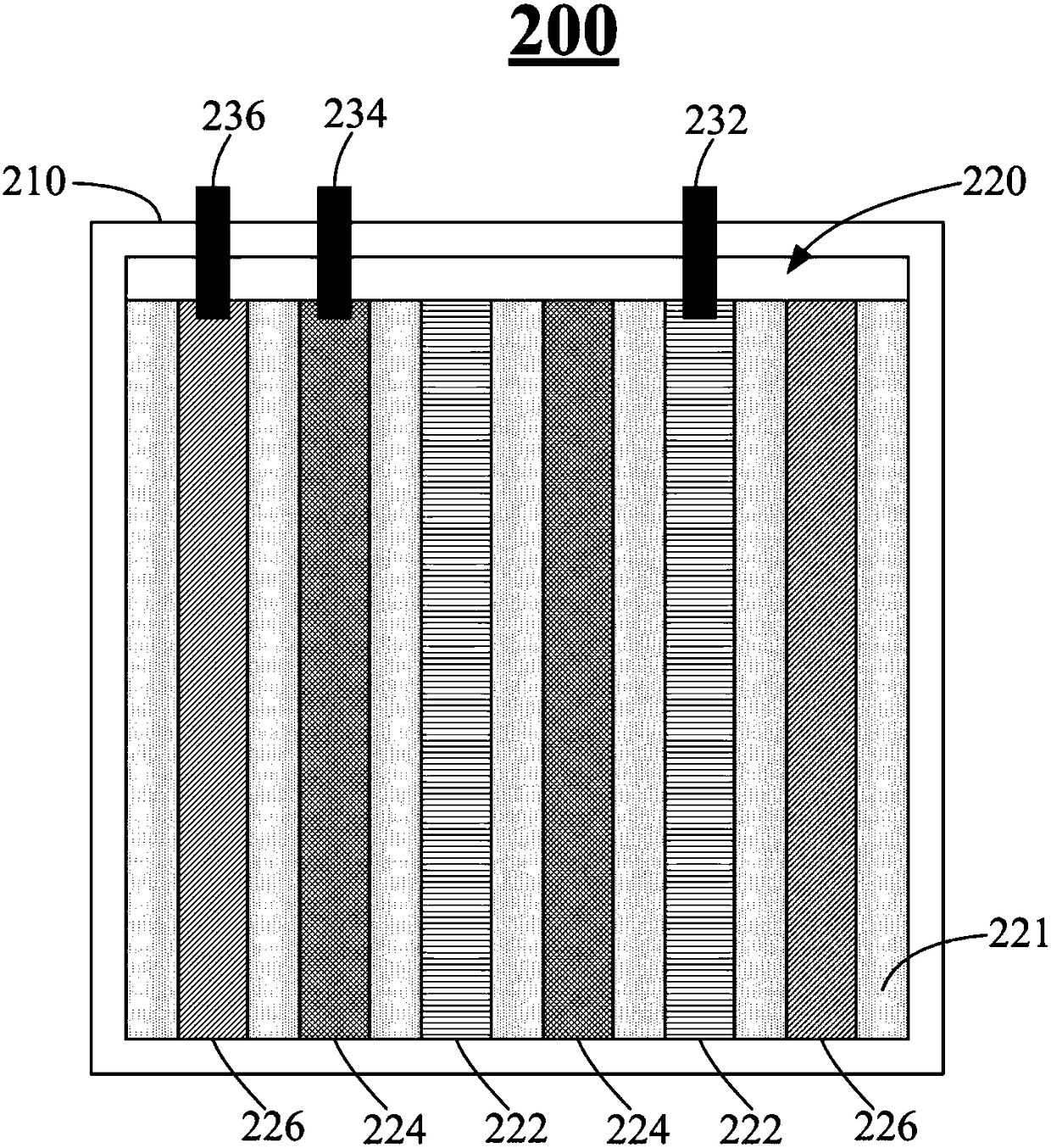

example 1

[0046] A 1Ah lithium cobaltate / graphite soft-packed battery cell is prepared by stirring, coating, rolling, pole piece cutting, baking pole piece, and lamination. The capacity ratio N / P of the negative electrode material and the positive electrode material is about 1. After winding a layer of separator, place a lithium supplementary pole piece on the left side of the dry cell to make a lithium supplementary dry battery cell. The lithium supplementary pole piece includes a copper foil current collector and a metal lithium layer formed on the current collector. The tabs are welded for lithium-supplementing dry cells, wherein the tabs for lithium-supplementing are nickel tabs, then packaged and injected with electrolyte to form a secondary battery. Cycling at 0.5°C, replenishing lithium with a capacity of 0.03Ah to the positive electrode after charging in the first week, the efficiency in the first week is 95%. After subsequent weekly charging, lithium with a capacity of 0.001425...

example 2

[0048]A 1Ah lithium cobaltate / silicon negative electrode soft-packed battery is prepared by stirring, coating, rolling, pole piece cutting, baking pole piece, and lamination. The N / P ratio is about 1.1. After winding a layer of separator, On the left side of the dry cell, a lithium-aluminum alloy strip pole piece with a steel mesh current collector nickel tab is placed to make a lithium-supplemented dry cell. The tabs are welded for lithium-supplementing dry cells, and packaged into a casing to form a secondary battery. Cycling was performed at 0.5°C, and 0.1Ah of lithium was added to the negative electrode after the first week of charging. After subsequent weekly charging, 0.14Ah capacity lithium was added to the silicon negative electrode. After 20 weeks of cycling, the Coulombic efficiency is 99.87%, and the capacity retention rate is 87.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com