Circuit topology for eliminating pwm noise of dual three-phase motor driven by h-bridge

A dual-phase, circuit technology, applied in AC motor control, motor vibration suppression control, electrical components, etc., can solve the problems of increased weight and cost of LC filters, increased order of motor control systems, and increased line impedance, etc. Achieve high application value and economic value, eliminate audible noise, and eliminate electromagnetic vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below with reference to the accompanying drawings, but it should be covered by modifying or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the present invention, without departing from the spirit and scope of the present invention. In the scope of protection.

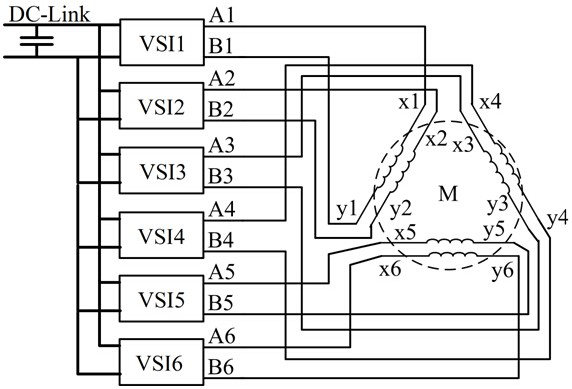

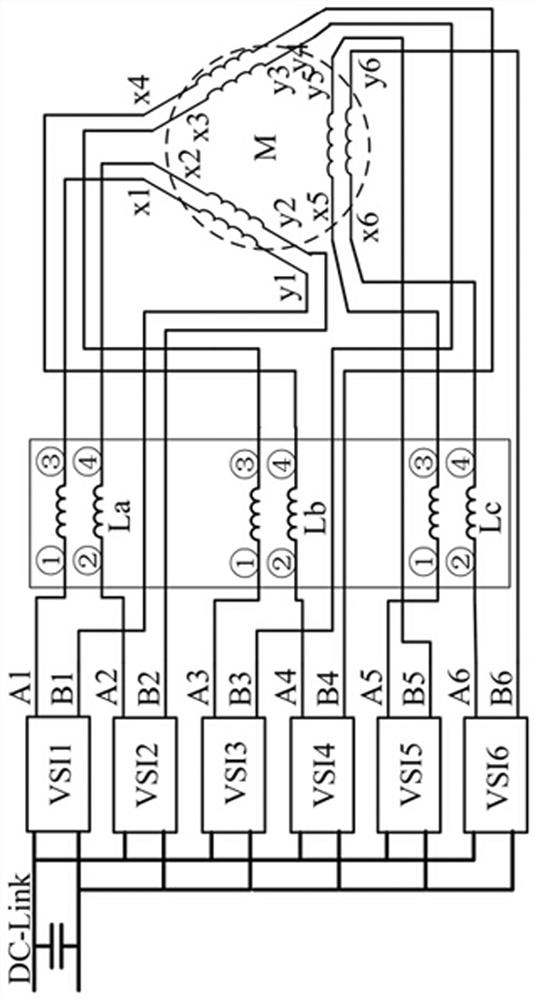

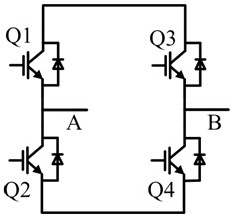

[0035] like figure 1 As shown, the traditional H-bridge-driven double-phase motor circuit topology contains six identical voltage source inverters vsi1, vsi2, vsi3, vsi4, vsi5 and vsi6 and a two-phase motor M, VSI's circuit topology image 3 Indicated. Six voltage source inverters VSI1, VSI2, VSI3, VSI4, VSI5, and VSI6 are connected in parallel on the same bus DC_LINK; the output terminals A1, B1, and the two-three-phase motor M of the voltage source inverter VSI1 X1, Y1 Connected; the output terminals A2, B2, and the two-three phase motor M of the voltage source inverter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com