Stumping harvester for caragana korshinskii

A harvester and stubble flat technology, applied to harvesters, cutters, agricultural machinery, etc., to achieve high work efficiency, reduce production costs, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

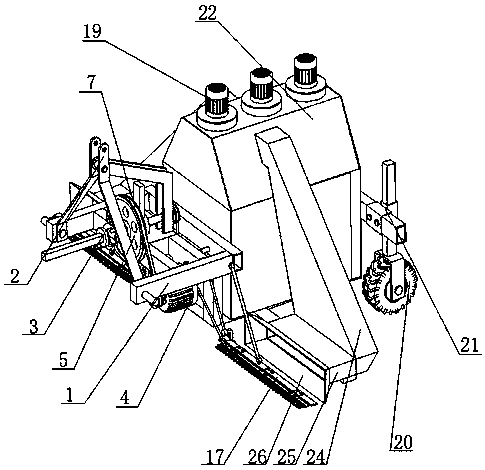

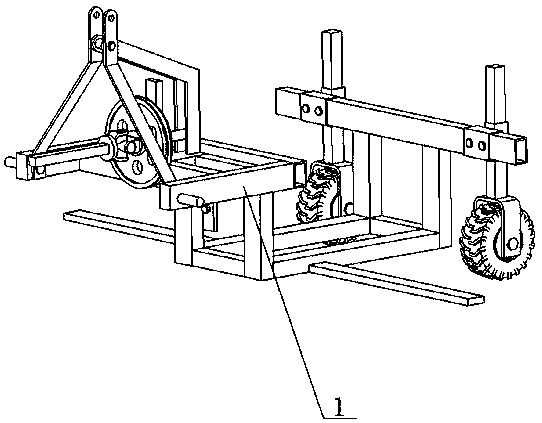

[0036] Embodiment 1: as Figure 1~11 As shown, the caragana stubble harvester includes a frame 1, a suspension device 2, a transmission part, a recovery part, two walking parts and two cutting parts;

[0037]The frame 1 is fixed with a suspension device 2, the two cutting parts are respectively located on both sides below the frame 1, and the two cutting parts are respectively connected with the transmission parts, and the transmission parts are located on the frame 1, And the suspension device 2 is located above the transmission part, the recovery part is fixed on the frame 1, and the recovery part is located on one side of the transmission part, and the two walking parts are respectively located on both sides of the recovery part, and The two running parts are connected with the frame 1 respectively.

[0038] The suspension device 2 is a three-point suspension device.

[0039] The cutting parts include connecting rod I14, connecting rod II15, connecting rod III16, reciproc...

Embodiment 2

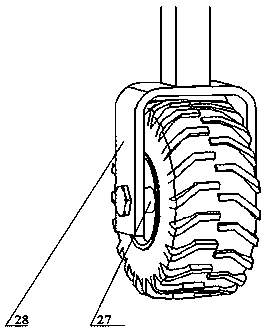

[0046] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, the difference is that the bottom of the ground wheel support 28 is fixed to the two ends of the ground wheel shaft 27, and the upper part of the ground wheel support 28 is raised and lowered by adjusting bolts. The device in the embodiment adjusts the chassis of the whole machine by raising or lowering it according to different road conditions, thereby changing the height of the ground wheels relative to the chassis of the whole machine, and realizing the adjustment of the chassis height of the whole machine.

[0047] The working principle of the present embodiment device is as follows:

[0048] When the whole machine is working, it is semi-suspended and installed behind the four-wheel tractor through the suspension device 2. The power output shaft of the tractor is connected to the cardan shaft 3 of the whole machine, and the cardan shaft 3 drives the coaxial driving pulley Ⅰ5 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com