Straw feed crushing equipment

A technology for crushing equipment and straw feed, applied in cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of short straw storage time, low feed quality, low feed concentration, etc., and achieve good rotation effect, high transmission efficiency, The effect of stable kinetic energy transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

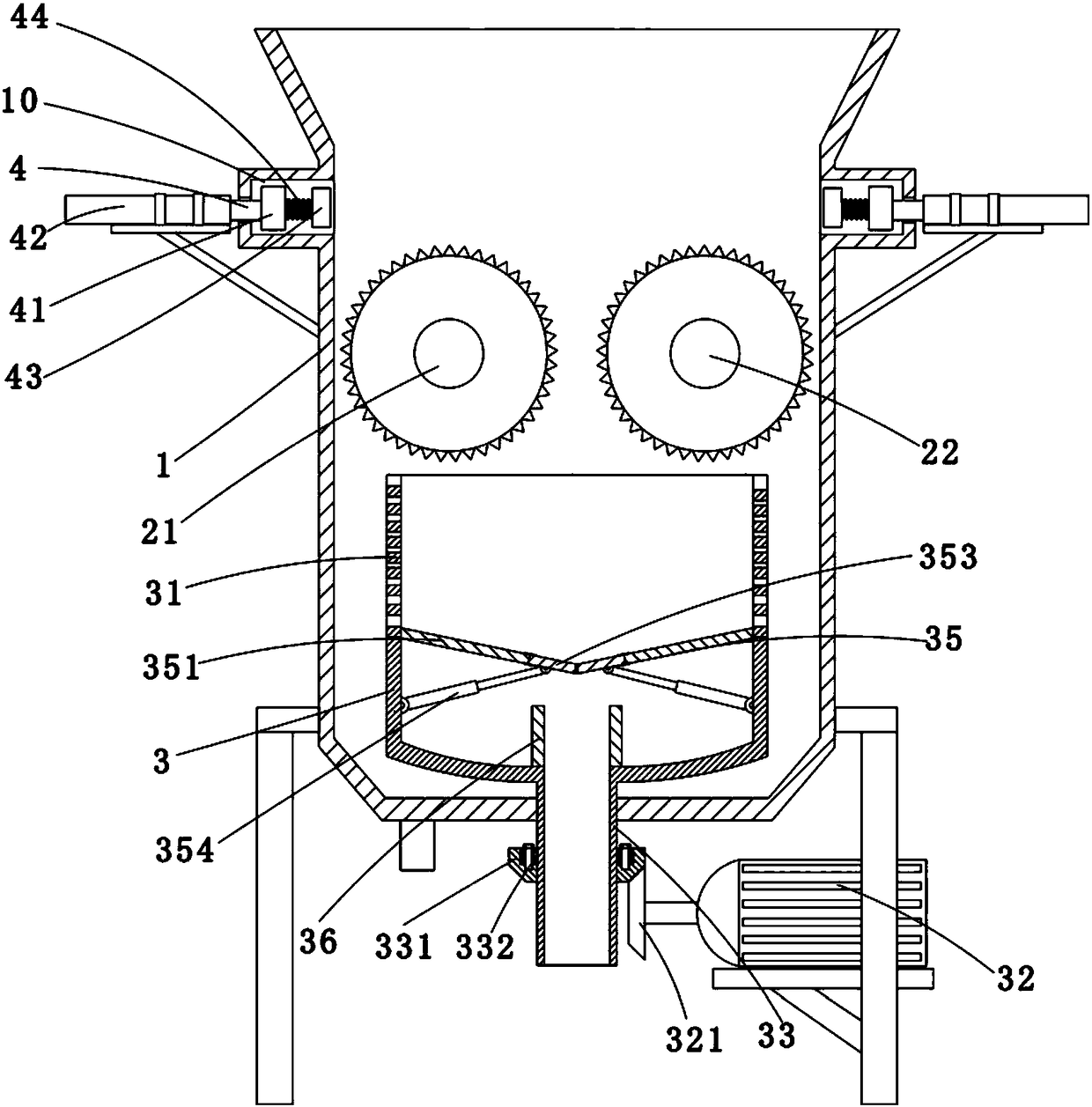

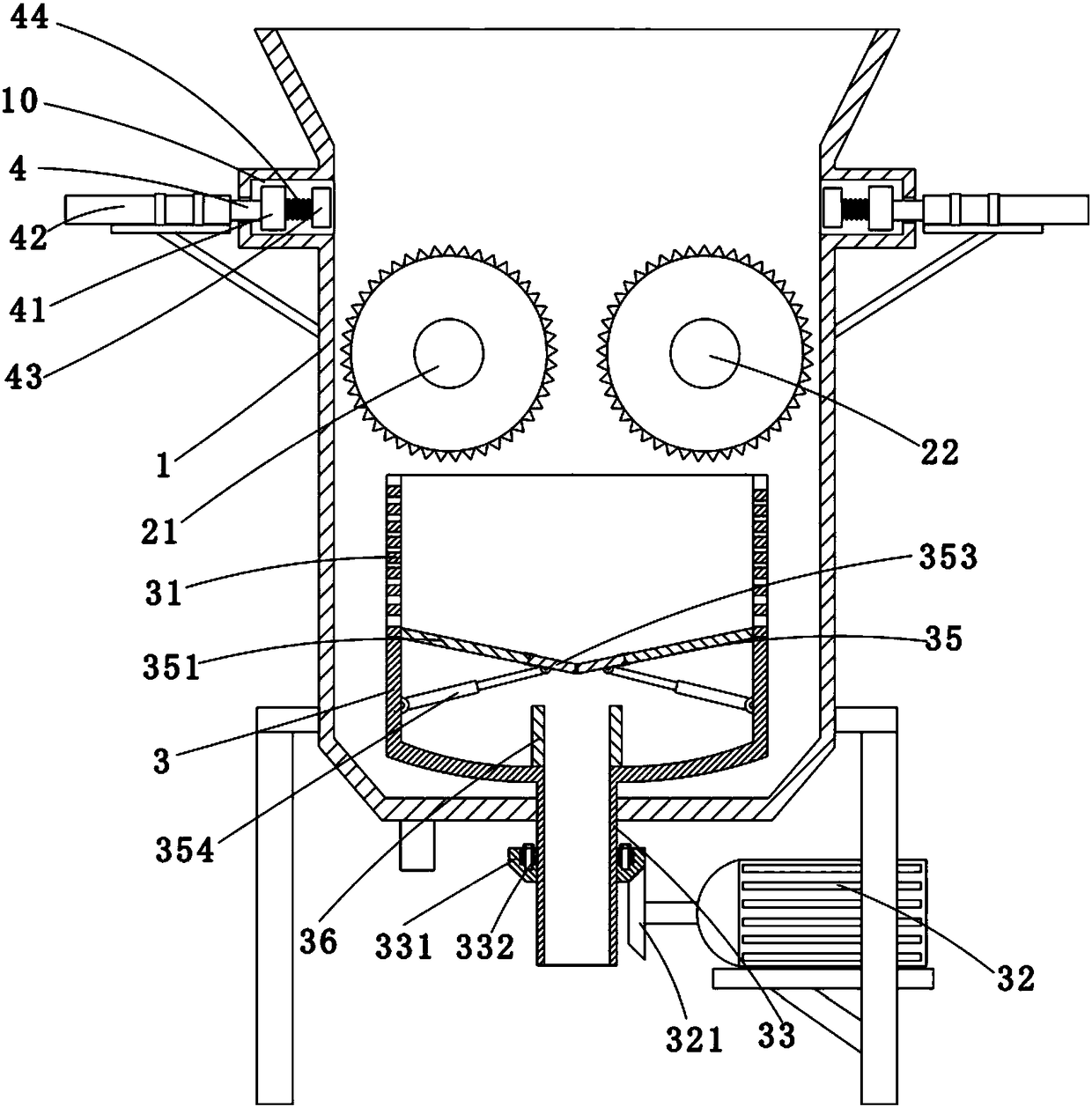

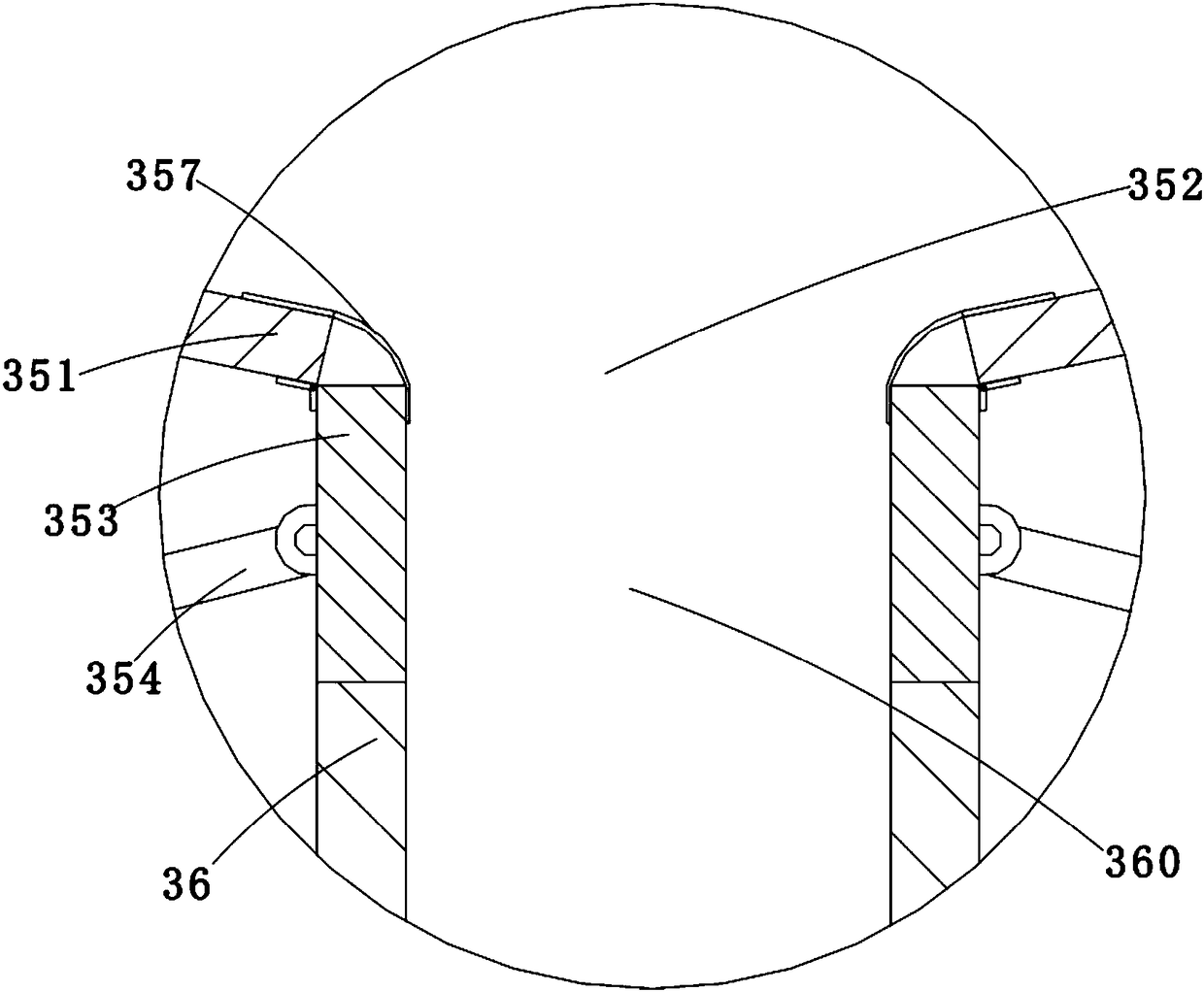

[0024] Such as Figure 1-8 As shown, a straw feed crushing equipment includes a casing 1, a first crushing roller 21, a second crushing roller 22 and a motor, the casing 1 is a metal shell, and the first crushing roller 21 and the second crushing roller 22 are metal rollers with protrusions on the sides, the first crushing roller 21 and the second crushing roller 22 are located on the same level, and there is a gap between the first crushing roller 21 and the second crushing roller 22, and the straw is When it falls into the gap, it will be squeezed and crushed; the motor is an existing motor on the market, and the motor drives the first crushing roller 21 and the second crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com