[0002] The world's

coating variety structure is developing towards the reduction of VOC, etc., and water-based coatings are one of the development directions. The proportion of traditional

solvent-based coatings in China is gradually decreasing, and the development speed of water-based coatings is also very fast, but low-grade polyvinyl alcohols still account for a large proportion.

Specific gravity, improving the quality of water-based coatings and developing new varieties are important links to consolidate and develop water-based coatings. The key research and development should be based on

vinyl acetate-acrylic acid

copolymer emulsion,

styrene-acrylic acid copolymer emulsion and pure acrylic acid series. Focus on coatings, and strive for breakthroughs in durability, paint film smoothness, fullness, construction, decoration, etc. For more mature

epoxy emulsions and water-based

polyurethane water-based base materials, research should continue to have high performance The water-based coatings meet the special requirements of some parts and develop towards high performance and high-grade. As an ideal performance of coatings, it is not only necessary to protect and beautify the substrate, but also to give the substrate itself special functions that cannot be possessed. Some new base materials are used. It can make the

coating achieve amazing high-performance, high value-added, and advanced effects, such as high

weather resistance fluororesin coatings, which can achieve good results when used in construction, because fluororesin coatings have better properties than other synthetic resins. Excellent

weather resistance, durability, and

chemical resistance, but fluororesin is relatively expensive, and its use in building exterior wall finishes is greatly limited. Attention should be paid to the development of fluororesin in water-based aspects, especially the use of

vinyl fluoride as a The copolymer emulsion modified by the main fluororesin makes it a high-quality base material with good performance, high grade and acceptable price, laying the foundation for the development of high-performance and high-grade coatings. In the research of water-based

polyurethane coatings On the one hand, efforts should be made to develop products.

Polyurethane is one of the high-grade materials with excellent performance. Making it water-based not only meets the requirements of reducing

pollution and saving energy, but also maintains the characteristics of

polyurethane itself. A general term for a class of liquid or

solid materials with protective, decorative or special properties (such as insulation, anti-

corrosion, signs, etc.)

solid coating film, including oil (based) paint, water-based paint,

powder coating

Lacquer is a flowable liquid paint, including oil (natural) paint and water-based paint. Paint uses organic solvents as the medium or high-

solid,

solvent-free oil-based paint. Water-based paint is a paint that can be dissolved or dispersed in water. Paint as a family One of the main materials of decoration accounts for a relatively large proportion in decoration. Whether the coating is qualified or not directly affects the overall decoration effect and the environment of the

living room, and sometimes even produces great harm to the health of the

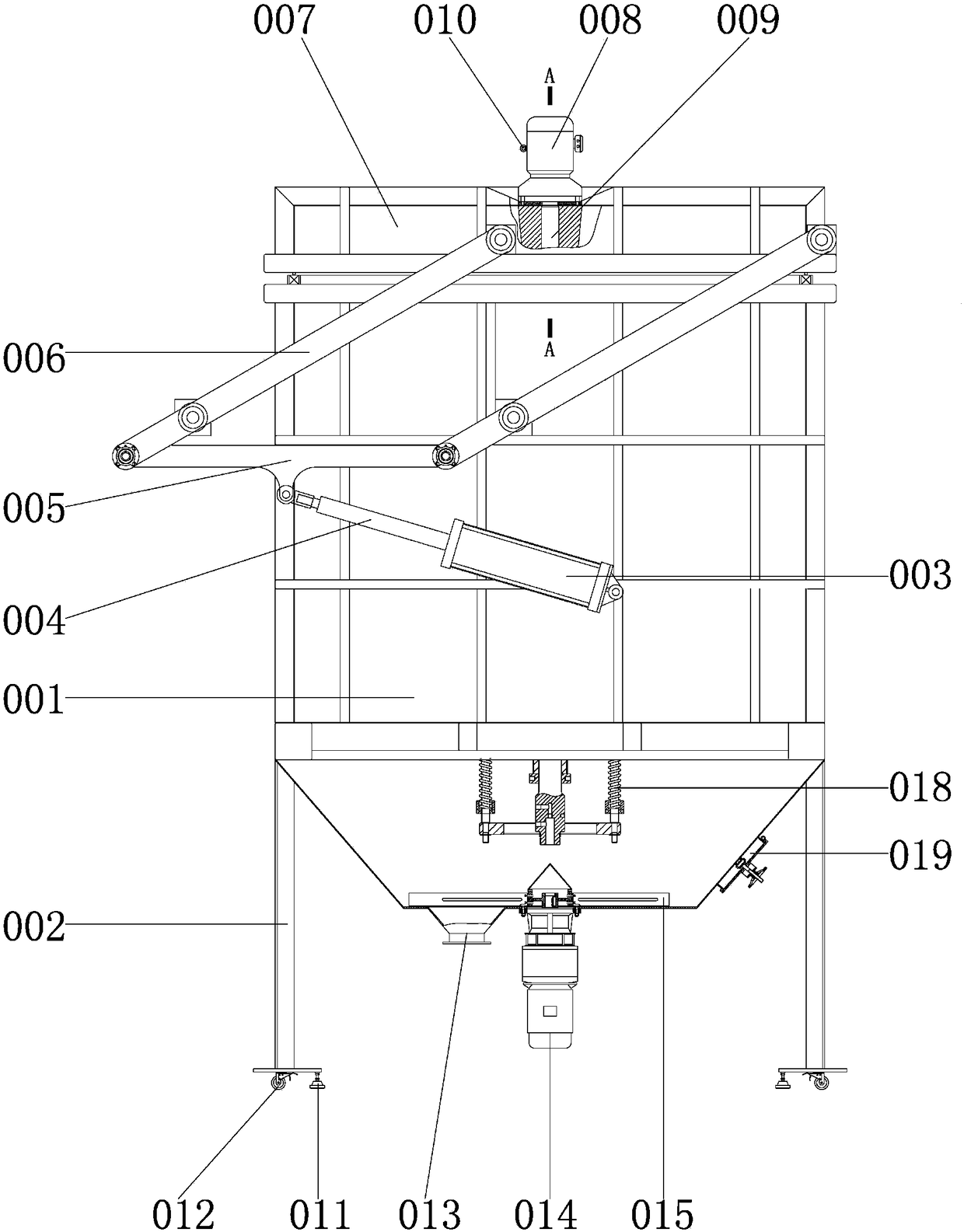

human body. In the prior art Among them, for example, the invention patent with application number 201621401547.3 includes a kettle body, a rotating motor, a stirring device, and a support frame. Through the top of the kettle body and extending into the kettle body, a plurality of stirring devices are arranged on the side wall of the rotating shaft located in the kettle body from top to bottom, and the stirring devices are two symmetrically arranged The hollow stirring rod, the front and rear sides of the hollow stirring rod are respectively provided with openings, the upper end of the kettle body is provided with a feed port, the lower end of the kettle body is provided with a

discharge port, and the bottom of the kettle body is provided with a The above-mentioned support frame, although the invention has a simple structure, there are many deficiencies and defects. In the existing equipment, the design of the kettle body has defects. When in use, the kettle body is not easy to move or transfer, which causes inconvenience to the movement and transfer of the kettle body , when transporting, it needs to be transported manually, which increases the

workload of the operation work, makes the operator feel physically fatigued and reduces the work efficiency, and the connection between the rotating motor and the kettle body is unstable. During use, the rotating The connection position between the motor and the kettle body is prone to tremors, which will damage the shaft, reduce the service life of the shaft, and increase the cost of use. In view of these situations, in order to avoid the above-mentioned technical problems, it is necessary to provide a new type of movable high-efficiency energy-saving coating for paint. Two-way stirred tank to overcome the defects in the prior art

Login to View More

Login to View More  Login to View More

Login to View More