Automatic test mechanical arm device based on vision calibration, control system and control method thereof

A control system and device control technology, applied in the direction of manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of inaccurate positioning, no feedback device in the system, and inability to feedback errors, etc., to improve accuracy and real-time performance, and control quickly Accurate, anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

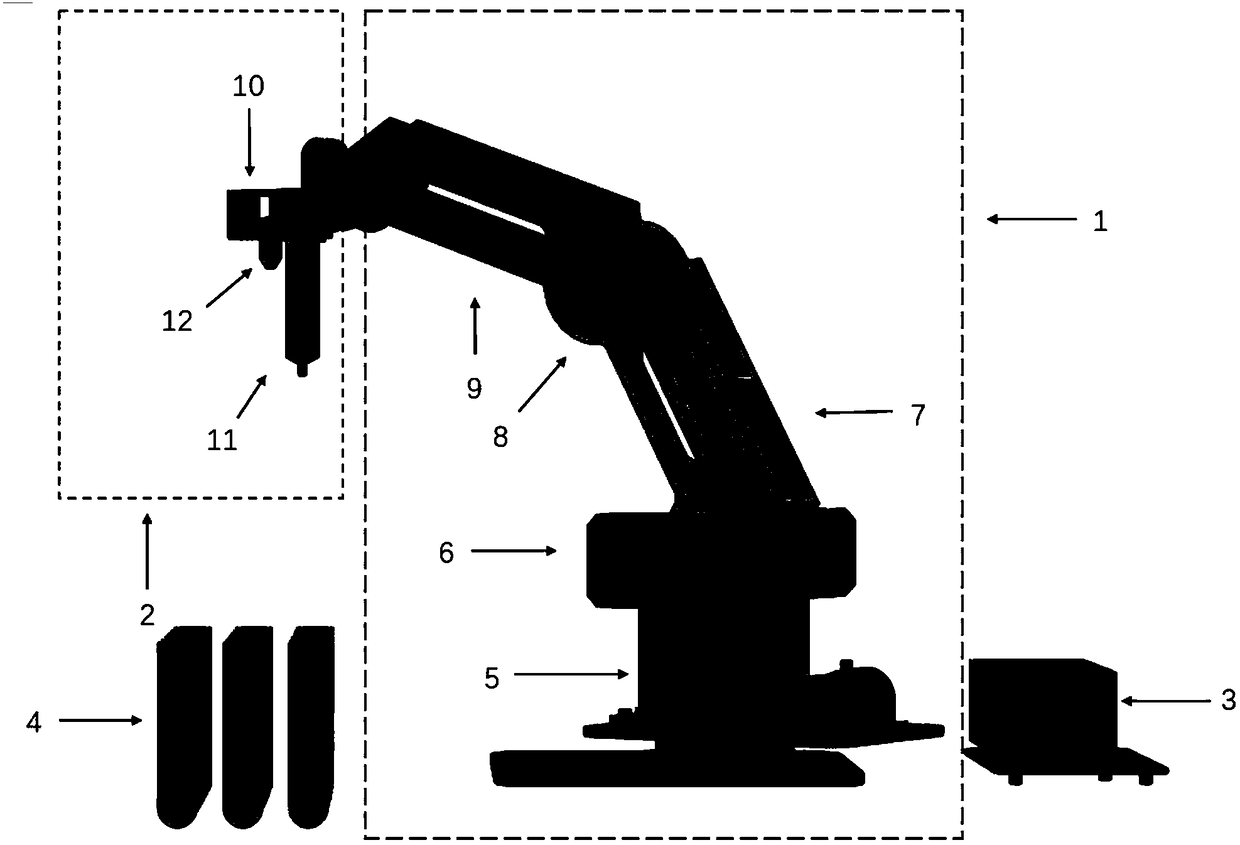

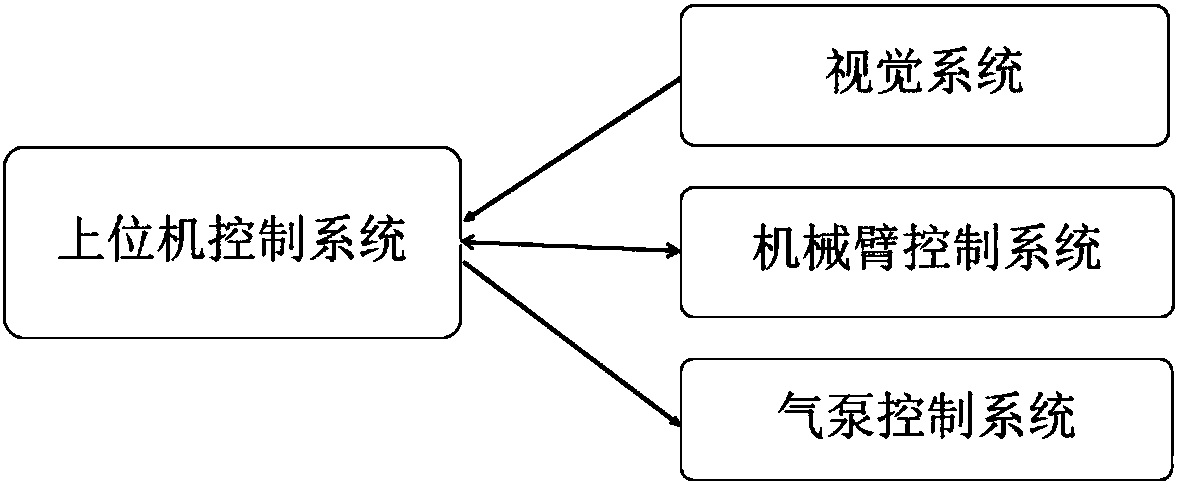

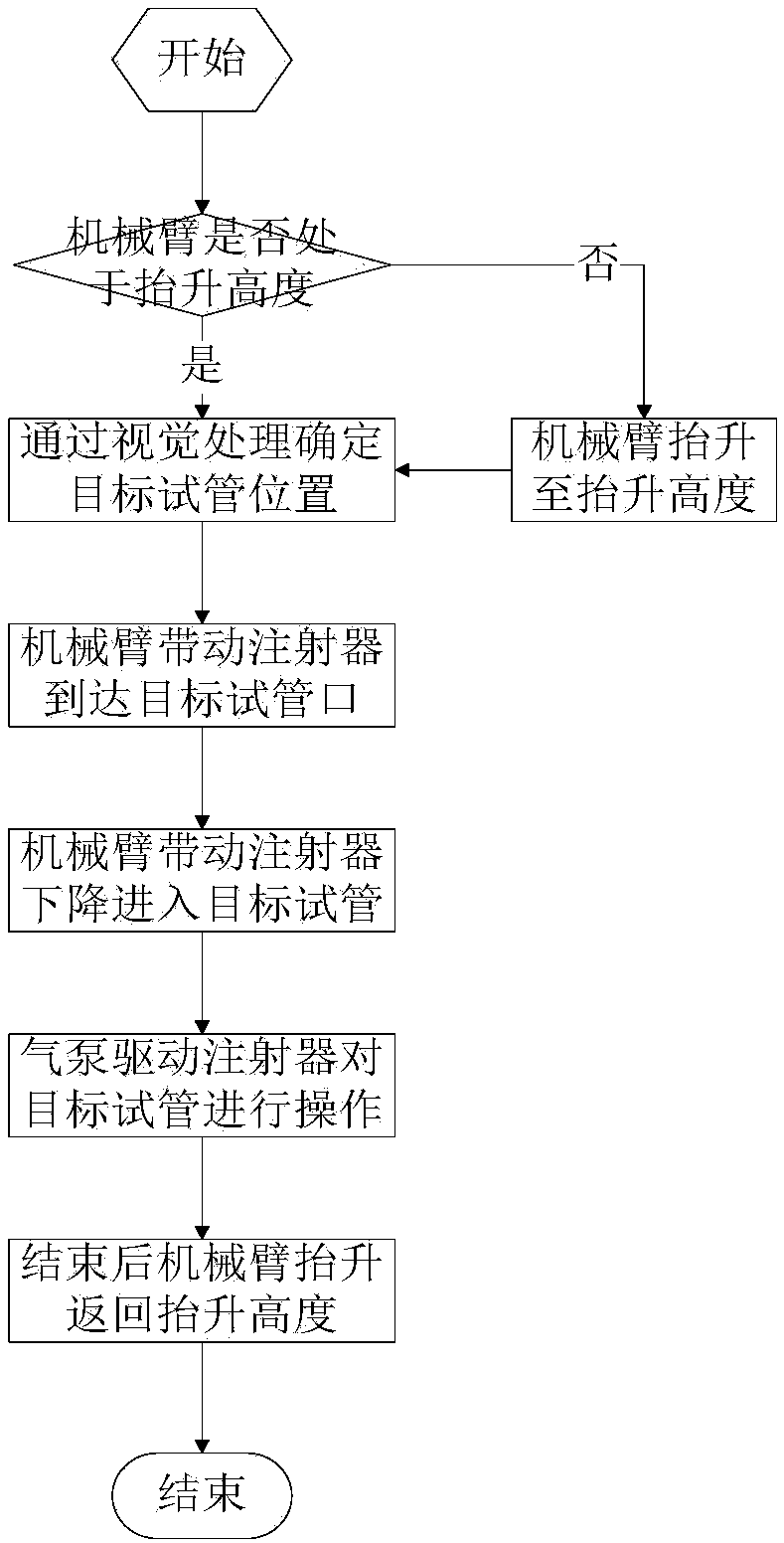

[0054]A new type of automatic testing robot arm device, control system and control method based on vision calibration of the present invention can automatically identify and locate the test tube and the position of the test tube rack through the visual system, and then realize automatic testing, which helps to reduce errors and improve testing efficiency. , Enhance the level of automation. Using monocular vision calibration, firstly, the three-dimensional model of the automatic testing robot arm and the test tube rack in space is established. Then, visually recognize the position of the test tube rack and locate each test tube arranged on the test tube rack. Furthermore, the movement of the mechanical arm in the operating space is controlled so that the mechanical arm drives the syringe mounted on the end effector of the mechanical arm to move to the test tube opening of the target test tube. Finally, the syringe is driven by the air pump to absorb or discharge the sample in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com