Method and internal combustion engine for determining the load state of a particulate filter

A particulate filter, load state technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of pressure drop, turbine power drop, compressor pressure ratio drop, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

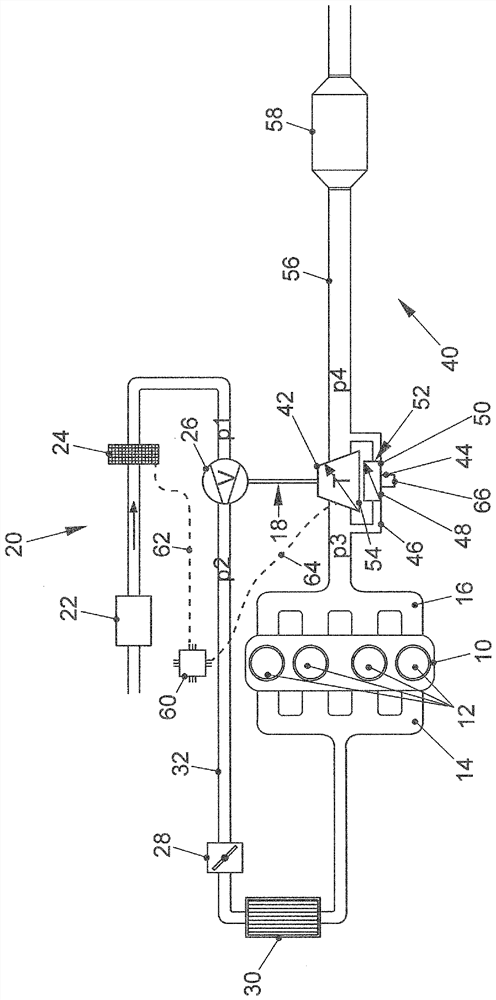

[0053] figure 1 An internal combustion engine 10 for a motor vehicle is shown. The internal combustion engine 10 has a combustion chamber 12 in which a fuel-air mixture is combusted. Internal combustion engine 10 is coupled via inlet 14 to an air supply system 20 of internal combustion engine 10 . The air supply system 20 comprises an air filter 22 in the flow direction of fresh air through a fresh line 32 of the air supply system 20 and an air mass meter 24 , preferably a hot-film air mass meter, downstream of the air filter 22 . Downstream of the air mass meter 24 , a compressor 26 of the exhaust gas turbocharger 18 is arranged in the fresh air line, with which compressor 26 fresh air is compressed for better filling of the combustion chamber 12 . A throttle plate 28 for controlling the amount of air supplied to the combustion chamber is arranged downstream of the compressor 26 . In addition, a charge air cooler 30 is arranged downstream in the fresh air line 32 between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com