Coating method for carbon brake disk anti-oxidation coating

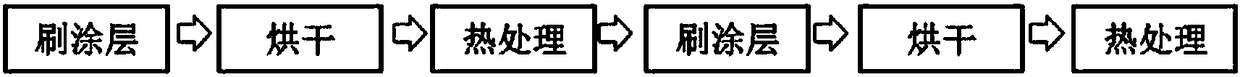

A technology for carbon brake discs and anti-oxidation, which is applied in coatings, devices for coating liquids on surfaces, and surface pretreatment, etc., which can solve the problems of high viscosity of coating precursor liquid at room temperature, difficult operation by workers, and coating treatment cycle Long and other problems, to achieve the effect of shortening the coating treatment cycle, shortening the production cycle, and shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

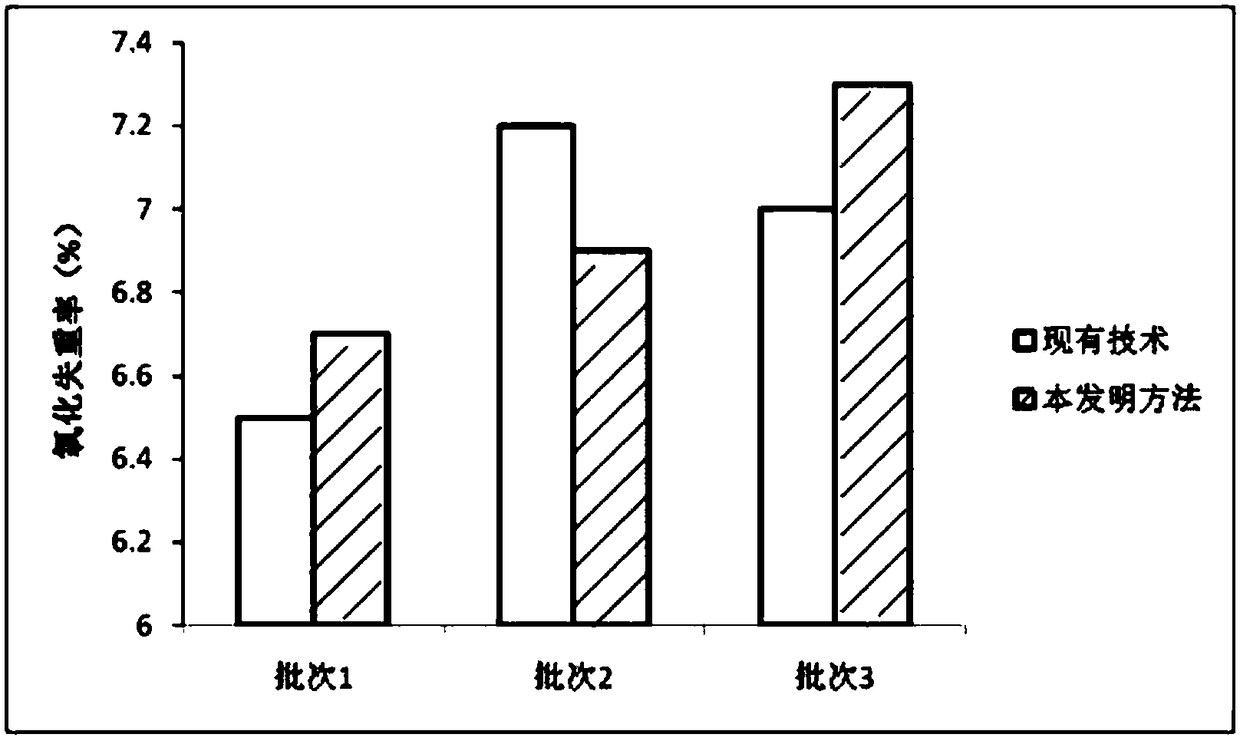

[0021] Embodiment 1: The present invention is applied to the early warning LS-108D brake disc, and a total of 75 workpieces in three batches are compared before and after the coating process is changed. The changed coating process: Pour the prepared carbon brake disc anti-oxidation coating into a beaker, put the beaker into a magnetic stirrer for heating and stirring, the holding temperature is 40°C, and the holding time is 15 minutes. Stir continuously. The results show that: the average painting time of a single workpiece is shortened from 10 minutes to 5 minutes, the coating treatment cycle is shortened from 10 working days to 7 working days, the rework rate is reduced from 37% to 8%, and the average anti-oxidation performance is not lower than that of traditional process, see image 3 .

Embodiment 2

[0022] Embodiment 2: The present invention is applied to the LS-129B brake disc of J10B, and a comparison is made of three batches of 84 workpieces before and after the coating process is changed. The changed coating process: Pour the prepared carbon brake disc anti-oxidation coating into a beaker, put the beaker into a magnetic stirrer for heating and stirring, the holding temperature is 60°C, and the holding time is 20 minutes. Stir continuously. The results show that the painting time of a single workpiece is shortened from 7min to 2min, the coating treatment cycle is shortened from 9 working days to 5 working days, the rework rate is reduced from 25% to 6%, and the average anti-oxidation performance is not lower than the traditional process , see Figure 4 .

Embodiment 3

[0023] Embodiment 3: The present invention is applied to the LS-158 brake disc of J-15, and a comparison is made of three batches of 198 workpieces before and after the coating process is changed. The changed coating process: Pour the prepared carbon brake disc anti-oxidation coating into a beaker, put the beaker into a magnetic stirrer for heating and stirring, the holding temperature is 50°C, and the holding time is 40 minutes. Stir continuously. The results show that the painting time of a single workpiece is shortened from 10 minutes to 4 minutes, the coating treatment cycle is shortened from 16 working days to 11 working days, the rework rate is reduced from 23% to 6%, and the average anti-oxidation performance is not lower than that of the traditional process , see Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com