Electric vehicle embedded hub motor integrated thermal management system

A thermal management system and in-wheel motor technology, applied in electric vehicles, motors, electric components, etc., can solve the problems of shortened brake disc life, potential safety hazards, increased temperature rise of the brake system, etc., to achieve reasonable structure and controllable heat transfer power , space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

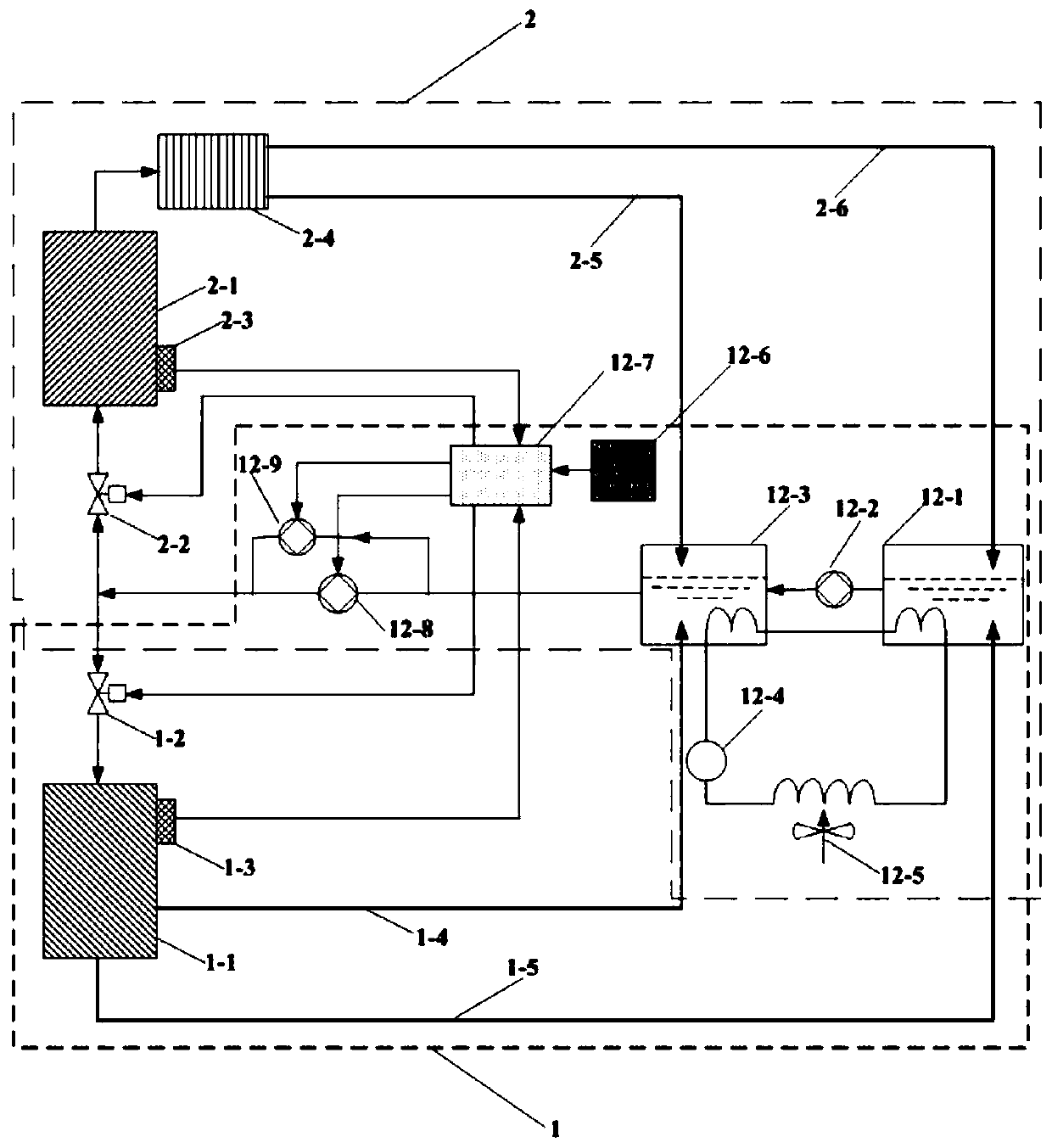

[0038] Such as figure 1 As shown, an electric vehicle embedded in-wheel motor comprehensive thermal management system according to an embodiment of the present invention includes an embedded magnetic steel heat dissipation system 1 and a brake disc spiral guide fin heat dissipation system 2 . It is applied to an embedded hub motor of an electric vehicle, and the hub motor is a product in the prior art.

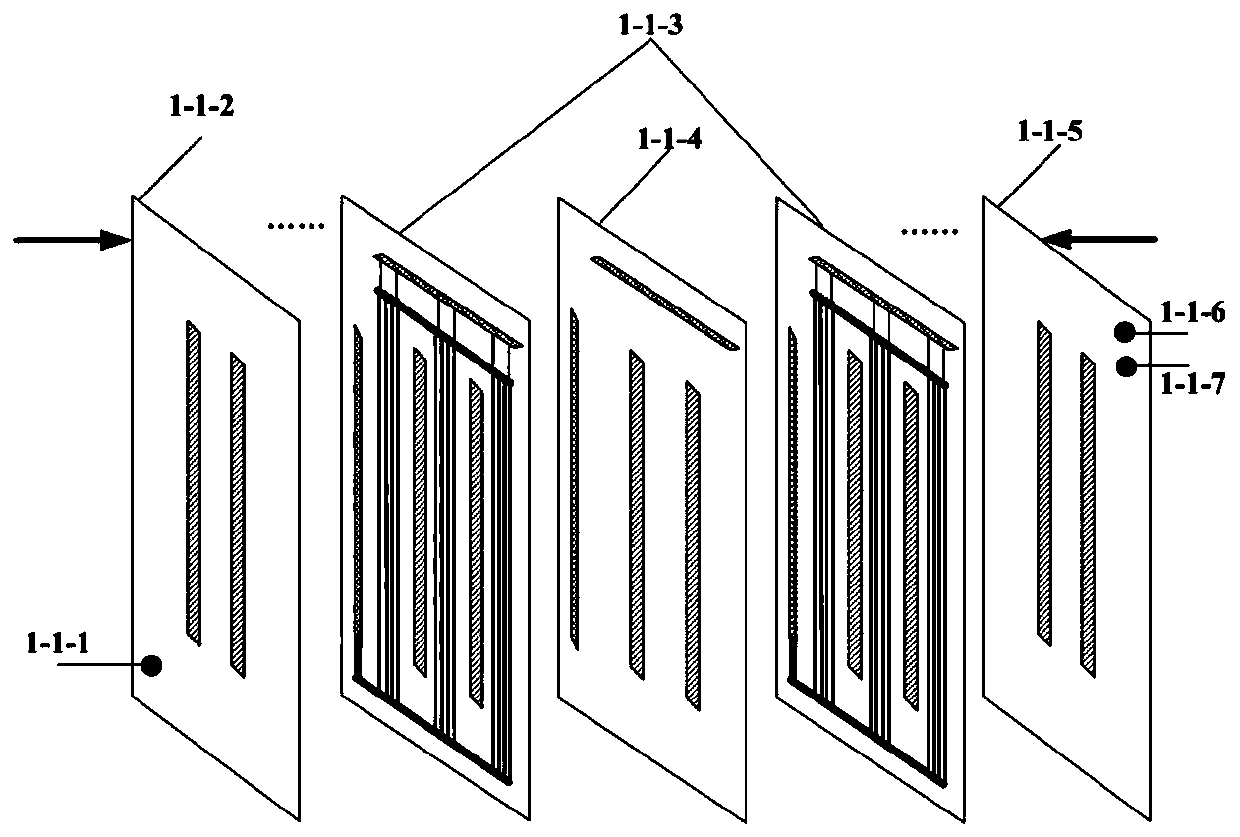

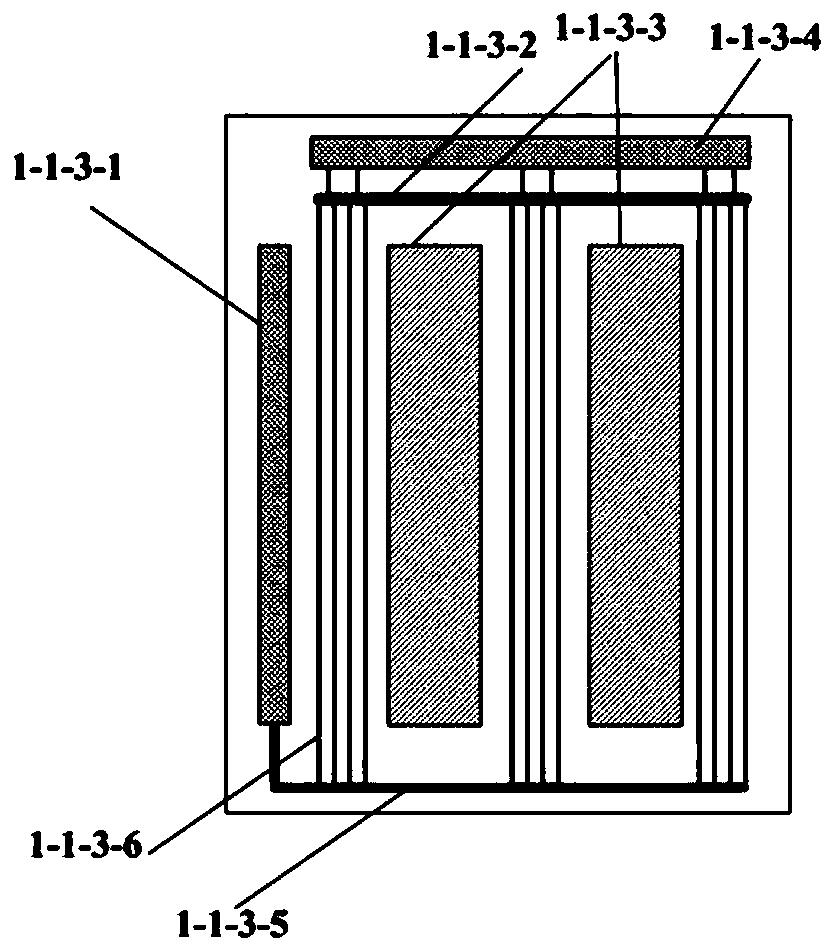

[0039] Embedded magnetic steel heat dissipation system 1 includes embedded magnetic steel 1-1, solenoid valve A 1-2, temperature sensor A 1-3, solution return pipeline 1-4A, steam return pipeline A 1-5, condensed water storage Filling 12-1, solution pump A 12-2, integrated solution storage tank 12-3, booster pump 12-4, fan 12-5, power supply 12-6, controller 12-7, solution pump B 12-8 and Solution Pump C 12-9, Embedded Magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com