Preparation method for lime nitrogen

A technology of lime nitrogen and raw materials, applied in the direction of cyanamide, etc., can solve problems such as consumption, and achieve the effect of reducing production cost, eliminating solid waste and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

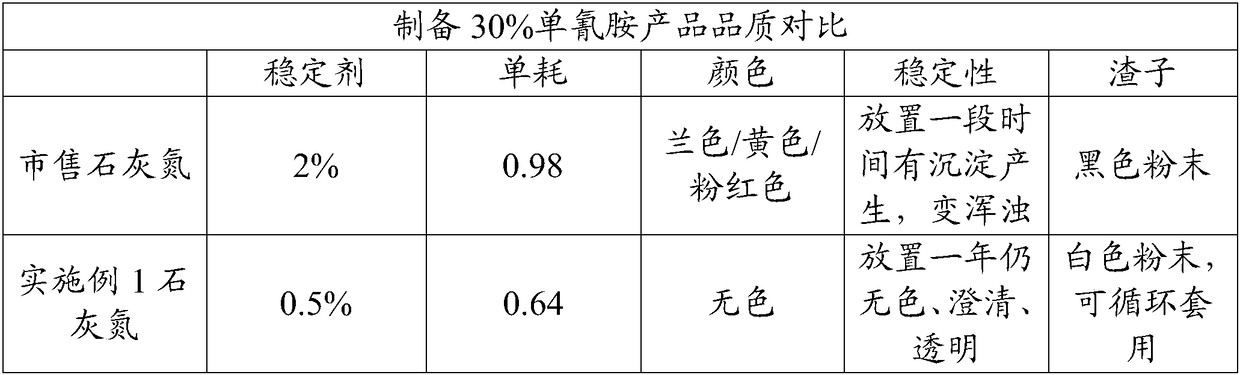

Examples

Embodiment 1

[0023] A kind of preparation method of lime nitrogen, concrete steps are as follows:

[0024] Place industrial light calcium carbonate in a high-temperature reaction furnace, feed ammonia gas 140 times the amount of calcium carbonate, and perform high-temperature calcination reaction at 400°C for 24 hours under an atmospheric pressure, and cool to room temperature after the reaction is completed. Material, the product is white or off-white solid powder, 33% of available nitrogen of calcium cyanamide is obtained, the content is 94.29%, and the yield is 92.04%.

Embodiment 2

[0026] A kind of preparation method of lime nitrogen, concrete steps are as follows:

[0027] Place industrial light calcium carbonate in a high-temperature reaction furnace, pass through ammonia gas 50 times the amount of calcium carbonate, carry out high-temperature calcination reaction at a pressure of -0.03MPa and a temperature of 700°C for 40 hours, and cool to room temperature after the reaction Discharging, the product is white or off-white solid powder, and 23% of calcium cyanamide available nitrogen is obtained, the content is 65.71%, and the yield is 57.29%.

Embodiment 3

[0029] A kind of preparation method of lime nitrogen, concrete steps are as follows:

[0030] Place industrial light calcium carbonate in a high-temperature reaction furnace, feed ammonia gas 200 times the amount of calcium carbonate, and perform a high-temperature calcination reaction at a pressure of -0.05MPa and a temperature of 350°C for 80 hours, and cool to room temperature after the reaction Discharging, the product is white or off-white solid powder, 25% of calcium cyanamide available nitrogen is obtained, the content is 71.43%, and the yield is 63.64%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com