Antistatic finishing technology of woolen textiles

A wool textile and anti-static technology, which is applied in the field of anti-static finishing technology, can solve problems such as static phenomena and serious static electricity, and achieve the effects of improving antistatic performance, improving quality of use, and reducing difficulty in processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

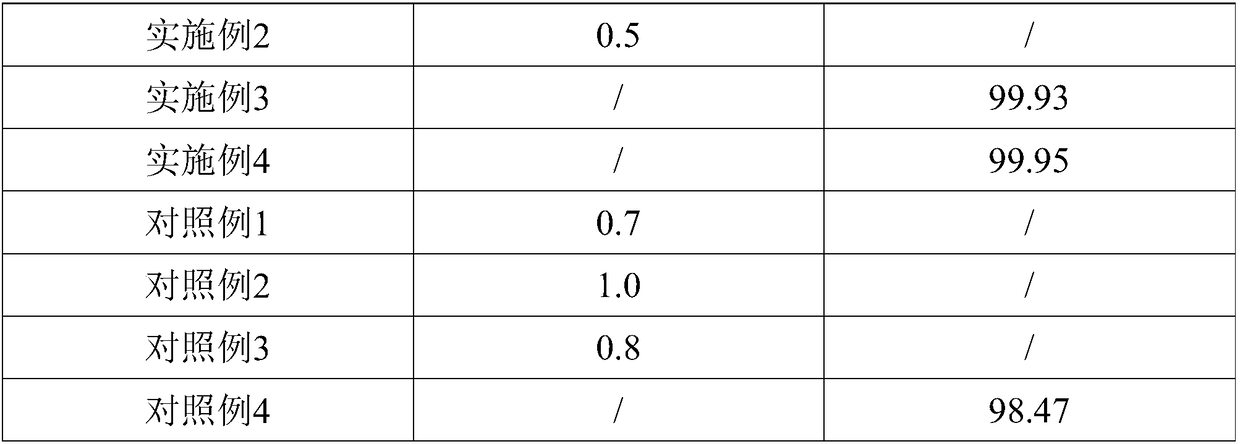

Examples

Embodiment 1

[0027] (1) Cleaning: Wash wool textiles with 20-30℃ water to remove residual grease and dust on the wool textiles, and dehydrate the washed wool textiles with a margin rate of 60-70%;

[0028] (2) Dipping: Immerse the washed wool textiles in the anti-static finishing liquid. The temperature of the anti-static finishing liquid is maintained at 60-70℃, and the immersion time is controlled at 15 minutes. After the immersion, the wool textiles are dehydrated and rolled. The remaining rate is 60-70%;

[0029] (3) Drying: Dry the above-mentioned dipped woolen textile at 70-80°C to reduce the moisture content to below 5%;

[0030] (4) Secondary immersion: the wool textile after the above drying is immersed in the anti-static finishing solution again, the anti-static finishing solution used is adjusted to pH 4-5 by dripping 70% dilute sulfuric acid, and the temperature of the anti-static finishing solution Maintain at 70-80℃, control the immersion time at 15min, do dehydration treatment to ...

Embodiment 2

[0035] (1) Cleaning: Wash wool textiles with 20-30℃ water to remove residual grease and dust on the wool textiles, and dehydrate the washed wool textiles with a margin rate of 60-70%;

[0036] (2) Dipping: Immerse the washed wool textiles in the anti-static finishing liquid. The temperature of the anti-static finishing liquid is maintained at 60-70℃, and the immersion time is controlled at 15 minutes. After the immersion, the wool textiles are dehydrated and rolled. The remaining rate is 60-70%;

[0037] (3) Drying: Dry the above-mentioned dipped woolen textile at 70-80°C to reduce the moisture content to below 5%;

[0038] (4) Secondary immersion: the wool textile after the above drying is immersed in the anti-static finishing solution again, the anti-static finishing solution used is adjusted to pH 4-5 by dripping 70% dilute sulfuric acid, and the temperature of the anti-static finishing solution Maintain at 70-80℃, control the immersion time at 15min, do dehydration treatment to ...

Embodiment 3

[0043] (1) Cleaning: Wash the wool textiles with 20-30℃ water to remove the residual grease and dust on the wool textiles, and dehydrate the washed wool textiles with a margin rate of 60-70%;

[0044] (2) Dipping: Immerse the washed wool textiles in the anti-static finishing liquid. The temperature of the anti-static finishing liquid is maintained at 60-70℃, and the immersion time is controlled at 15 minutes. After the immersion, the wool textiles are dehydrated and rolled. The remaining rate is 60-70%;

[0045] (3) Drying: Dry the above-mentioned dipped woolen textile at 70-80°C to reduce the moisture content to below 5%;

[0046] (4) Secondary immersion: the wool textile after the above drying is immersed in the anti-static finishing solution again, the anti-static finishing solution used is adjusted to pH 4-5 by dripping 70% dilute sulfuric acid, and the temperature of the anti-static finishing solution Maintain at 70-80℃, control the immersion time at 15min, do dehydration treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com