Large-pressure-angle worm driving mechanism

A technology of worm drive and high pressure, which is applied in transmission devices, friction transmission devices, mechanical equipment, etc., can solve the problems of worm gear or helical gear teeth that are easy to fail, and achieve high reliability, prolong working life, huge social benefits and The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

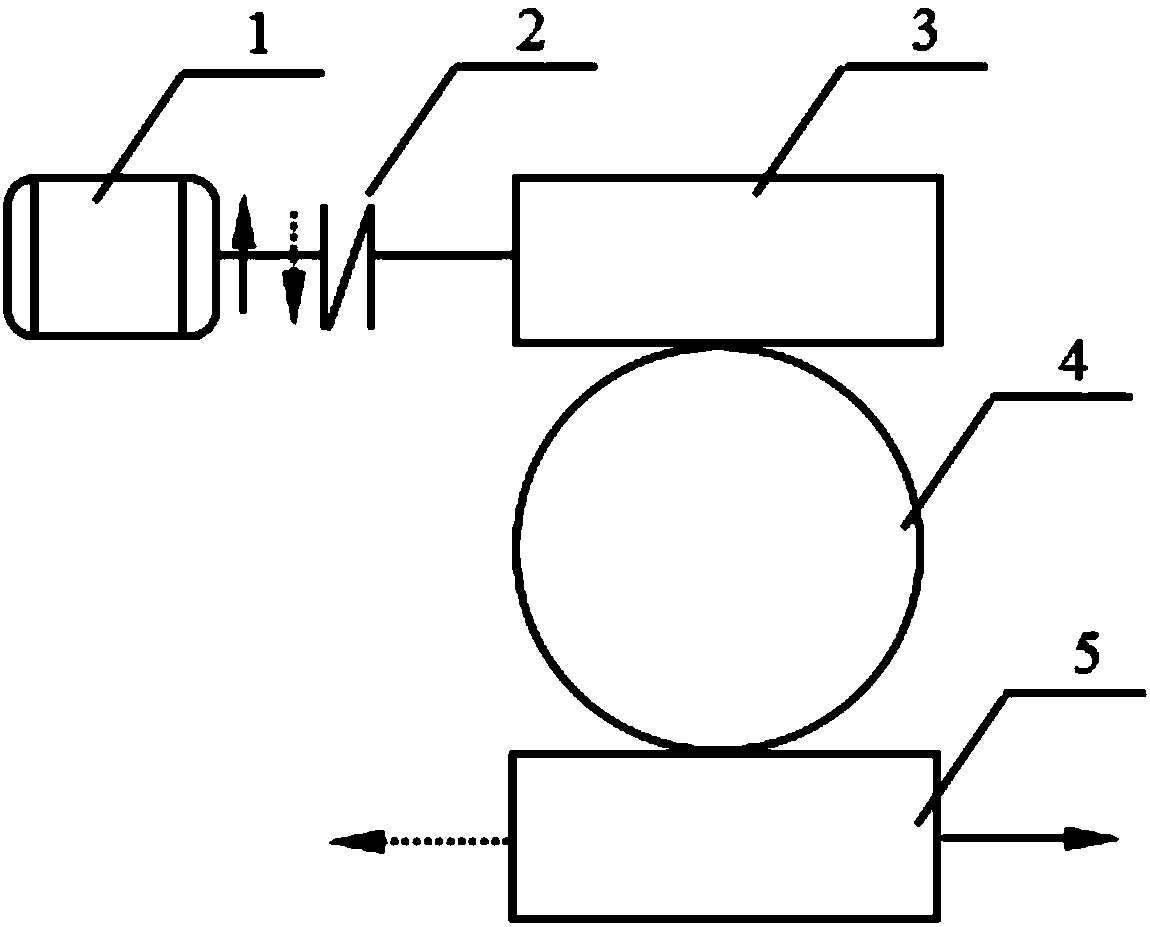

[0021] 1) For the convenience of analysis, it is assumed that the helical direction of the teeth of the worm 3 is left-handed. Take transmission wheel 4 as worm gear, because worm gear meshes with worm screw 3, then the gear tooth spiral direction of worm gear is also left-handed, and worm gear drives helical rack 5 to move, then the gear tooth helical direction of helical rack 5 is right-handed;

[0022] 2), such as figure 1 As shown, when the motor 1 rotates in the direction of the upward solid arrow, the worm 3 is driven to rotate through the coupling 2, and the rotation direction of the worm 3 is the same as that of the motor 1;

[0023] 3), take the number of heads, diameter coefficient, axial surface modulus, and axial surface pressure angle of the worm 3 as z 3 ,q 3 、m x3 、α x3 , where z 3 ,q 3 The value of can refer to the gear design manual; m x3 、α x3 It can be customized or obtained from the gear manual according to the needs, but the specific value is relat...

Embodiment 2

[0031] 1) For the convenience of analysis, it is assumed that the helical direction of the teeth of the worm 3 is left-handed, and the transmission wheel 4 is taken as a helical gear. Since the helical gear meshes with the worm 3, the helical direction of the helical teeth of the helical gear is also left-handed, and the helical gear drives When the helical rack 5 moves, the helical direction of the teeth of the helical rack 5 is right-handed;

[0032] 2), such as figure 1 As shown, when the motor 1 rotates in the direction of the upward solid arrow, the worm 3 is driven to rotate through the coupling 2, and the rotation direction of the worm 3 is the same as that of the motor 1;

[0033] 3), take the number of heads, diameter coefficient, axial surface modulus, and axial surface pressure angle of the worm 3 as z 3 ,q 3 、m x3 、α x3 , where z 3 ,q 3 The value of can refer to the gear design manual; m x3 、α x3 The value can be determined according to the needs or taken fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com