Reactive sputtering apparatus and reactive sputtering method

A sputtering device and reactive technology, applied in the field of reactive sputtering devices, can solve the problems of potential distribution change, large discharge voltage change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

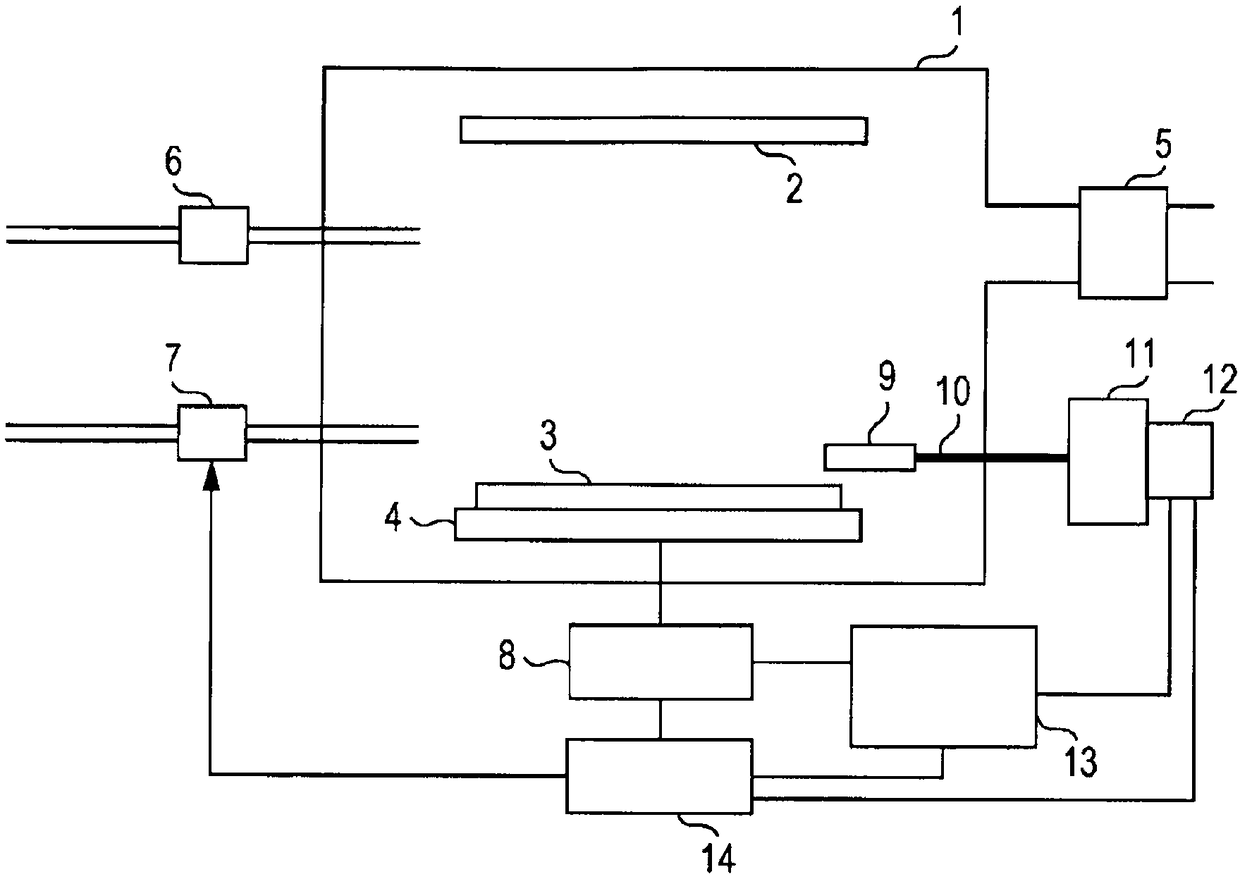

[0033] Refer below figure 1 Example 1 is described. The reactive sputtering device was constructed as follows.

[0034] The volume of the vacuum chamber: width 450mm x depth 450mm x height 500mm

[0035] Discharge mechanism: turbomolecular pump, dry pump

[0036] Power supply: DC pulse power supply

[0037] Target shape: diameter φ8 inches × thickness 5mm

[0038] Target material: Si

[0039] Inert gas: Ar

[0040] Reactive gas: O 2

[0041] Achievable pressure: 1×10 -5 Pa

[0042] A reactive sputtering device according to this example is described. A lens constituting a substrate 2 , a Si target 3 supplying a deposition material, and a cathode 4 electrically connected to the target 3 are arranged inside the vacuum chamber 1 . Ar gas and oxygen are introduced into the vacuum chamber 1 through a mass flow controller 6 that controls the amount of introduced Ar gas and through a mass flow controller 7 that controls the amount of introduced oxygen. These gases are disc...

example 2

[0053] In Example 1, the specified values for the PEM control monitor values are updated by taking data obtained during the previous deposition, while in Example 2, the values for The specified value of the PEM control monitor value.

[0054] The device configuration and processing flow are the same as in Example 1. A method of updating a specified value for a PEM control monitor value according to a feature of this example is described. Image 6 Indicates the initial PEM control monitoring value I measured in the preliminary measurement p and V / V at this time c The relationship between. The deposition was repeated three times, and the specified values for the PEM control monitoring values were updated by the method used in Example 1. In this example 2, according to each of the most recent plurality of depositions, the control unit 14 obtains the plasma emission intensity during the process from the compound mode through the transfer mode to the metal mode measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com