Friction energy dissipation combination node for assembly type self-resetting pre-stressed concrete framework

A friction energy consumption, combined node technology, applied in protective buildings/shelter, building types, buildings, etc., can solve problems such as poor energy consumption capacity, improve energy consumption capacity, reduce labor costs and environmental pollution, The effect of large additional damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

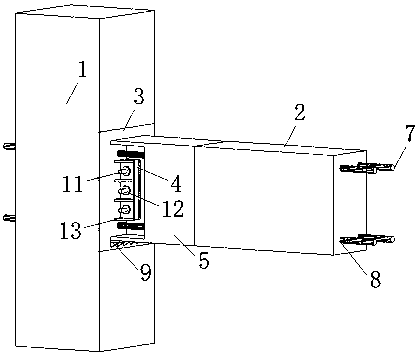

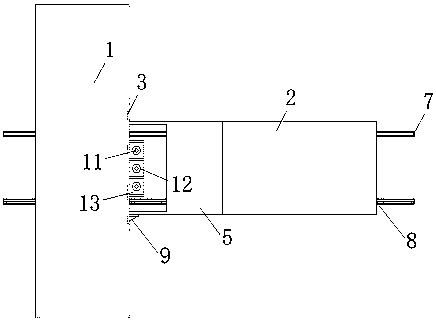

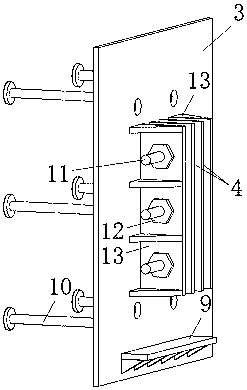

[0030] Such as Figure 1-6 As shown, the present invention discloses a prestressed assembled composite joint structure using frictional energy dissipation. The idea of the invention is to pre-embed a steel sleeve with section steel at the end of a prefabricated reinforced concrete beam on the basis of a prestressed assembled joint. In addition, friction energy dissipation devices are installed on both sides of the web of the section steel part to dissipate the seismic energy through friction, which is an assembled self-resetting frame composite node.

[0031] Such as Figure 1-6 As shown, an assembled self-resetting prestressed concrete frame friction energy dissipation combined node structure of the present invention includes prefabricated reinforced concrete columns 1, prefabricated reinforced concrete beams 2, pre-embedded steel plates 3 at column ends, friction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com