High-temperature heat shock method for promoting creation of microfracture on hydraulic fracture surface of tight gas well

A hydraulic fracture and tight gas technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problem of low fracturing fluid flowback rate, reservoir water phase trap damage, fracture network density Single scale and other problems, to achieve the effect of increasing the size of the effective flow channel and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

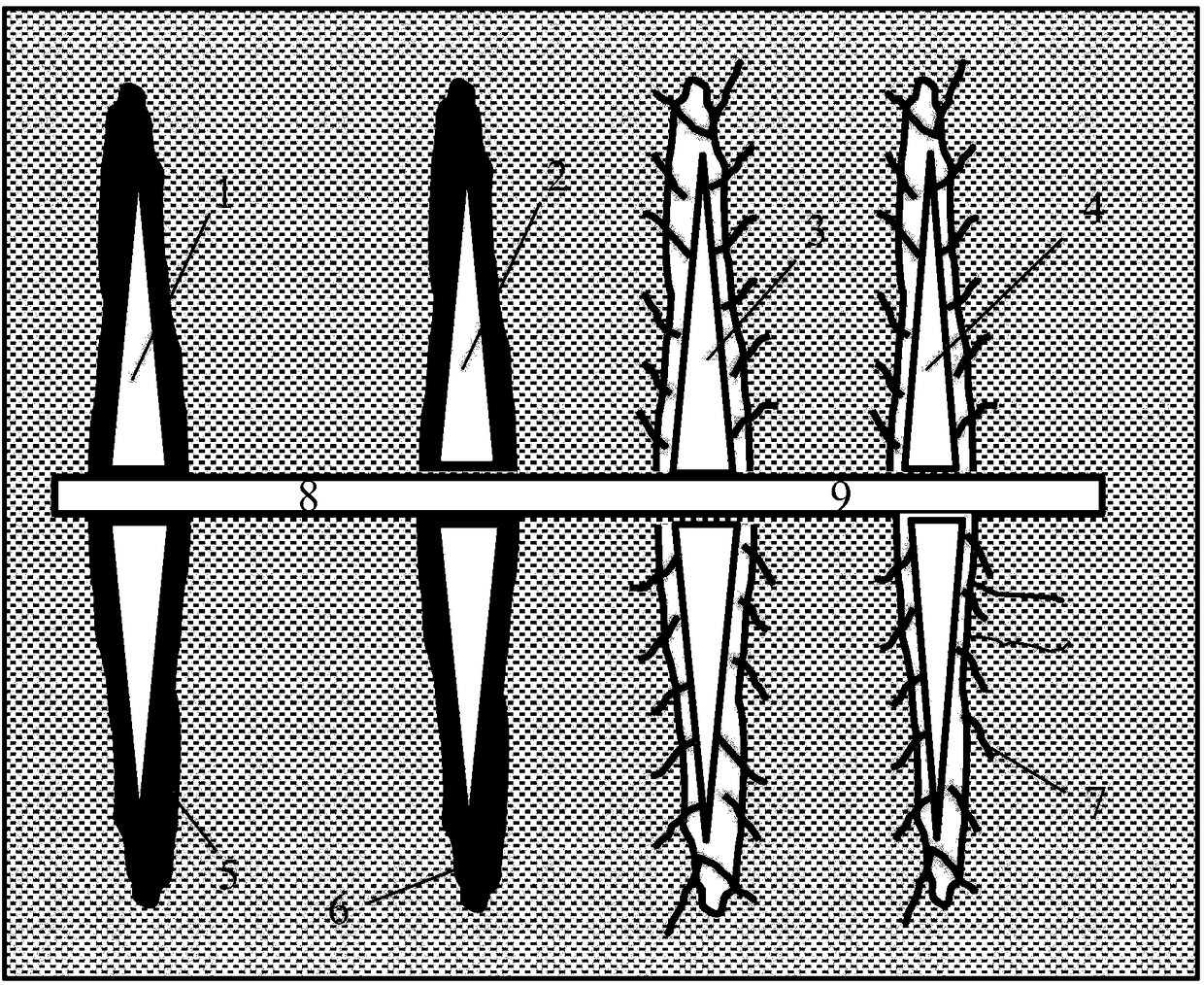

[0018] (1) Collect data such as hydraulic fracturing fluid volume, proppant addition, fracturing fluid flowback rate, stimulated fracture area, and gas well water production in selected tight gas wells in the work area, and focus on judging whether the produced water continues to contain formation water. Tight gas wells that do not produce formation water continuously are treated by the high temperature heat shock method.

[0019] (2) Select the tight reservoir cores to be treated, determine the realization form of the high-temperature thermal shock method according to different gas injection methods, carry out core heating experiments under the conditions of in-situ water saturation and in-situ effective stress in the room, and determine the core permeability A significant increase in the rate corresponds to the thermal rupture threshold temperature.

[0020] (3) Based on the fracturing fluid injection and flowback conditions collected in step (1) and the hydraulic fracturing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com