Honey Refining and Its Processing Technology

A processing technology and honey refining technology, which is applied in the field of honey refining and processing technology, can solve the problems of uneven product quality, inconsistent quality requirements, and affecting the quality of medicines, so as to improve color and viscosity, prolong storage time, pH Value changes for a stable and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

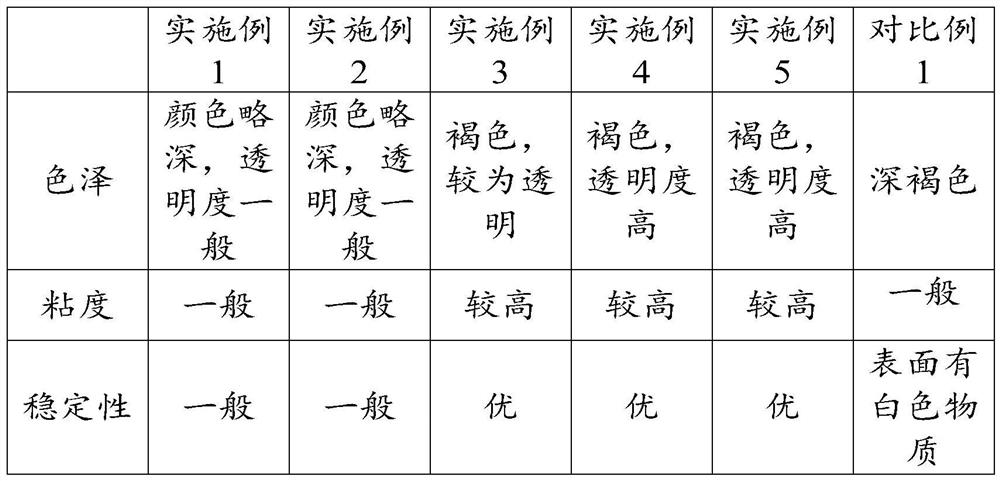

Examples

Embodiment 1

[0032] This embodiment provides a kind of refining honey, is made by following processing technology:

[0033] Choose fresh honey, mix honey and water evenly, and filter with gauze. Take the filtrate and add to the container.

[0034] After stirring the mixture to make it evenly mixed, control the flow rate of the air above the mixture so that when the flow rate is 0.8m / s, heat the mixture to 50-60°C at a heating rate of 10°C / min, keep it warm for 5min, and heat it at 5°C / min. The heating rate of min is to heat the mixture to 90°C and keep it warm for 10 min.

[0035] Under the conditions of 800MHz and 70°C, microwave sterilization for 2min. The water content of condensed honey after sterilization is 5%.

Embodiment 2

[0037] This embodiment provides a kind of refining honey, is made by following processing technology:

[0038] Choose fresh honey, mix honey and water evenly, and filter with gauze. Take the filtrate and mix it with the bacteriostatic agent and add it to the container. Wherein, the mass ratio of honey and antibacterial agent is 20:1. The antibacterial agent includes clove essential oil, lavender essential oil, rosemary essential oil and thyme essential oil with a mass ratio of 5:2:1:1.

[0039] After stirring the mixture to make it evenly mixed, heat the mixture to 55°C, keep it warm for 10 minutes, continue heating to 100°C, and keep it warm for 20 minutes.

[0040] Under the conditions of 900MHz and 80°C, microwave sterilization for 4min. The water content of condensed honey after sterilization is 7%.

Embodiment 3

[0042] This embodiment provides a kind of refining honey, is made by following processing technology:

[0043] Choose fresh honey, mix honey and water evenly, and filter with gauze. Take the filtrate and mix it with the bacteriostatic agent and add it to the container. Wherein, the mass ratio of honey and antibacterial agent is 40:3. The antibacterial agent includes clove essential oil, lavender essential oil, rosemary essential oil and thyme essential oil with a mass ratio of 6:3:1:2.

[0044]After stirring the mixture to make it evenly mixed, control the air flow rate above the mixture so that when the flow rate is 1.2m / s, heat the mixture to 55°C at a heating rate of 15°C / min, keep it warm for 10min, and then heat it at a rate of 8°C / min. Heating rate Heat the mixture to 95°C and keep it warm for 15 minutes.

[0045] Under the conditions of 1000MHz and 80°C, microwave sterilization for 5min. The water content of condensed honey after sterilization is 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com