a cs 3 cu 2 i 5 Ultraviolet detector and its film preparation method

A thin film and glass technology, applied in the field of lead-free perovskite thin film, can solve the problems of low luminous efficiency of blue light, easy decomposition, damage, etc., and achieve the effect of high fluorescence quantum efficiency, uniform and dense film, and low annealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

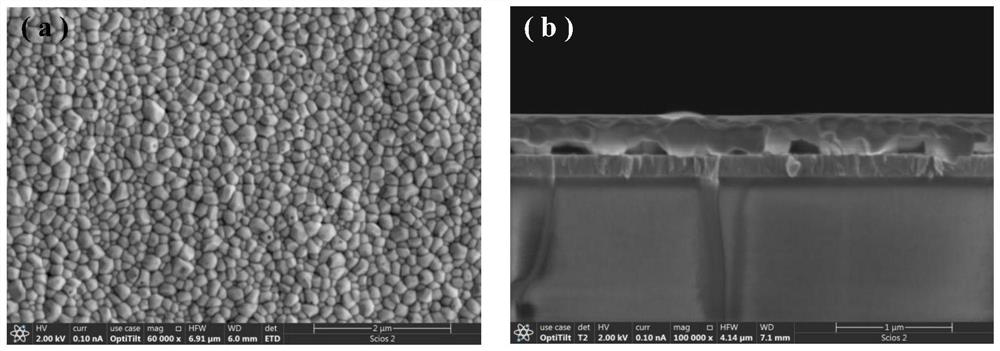

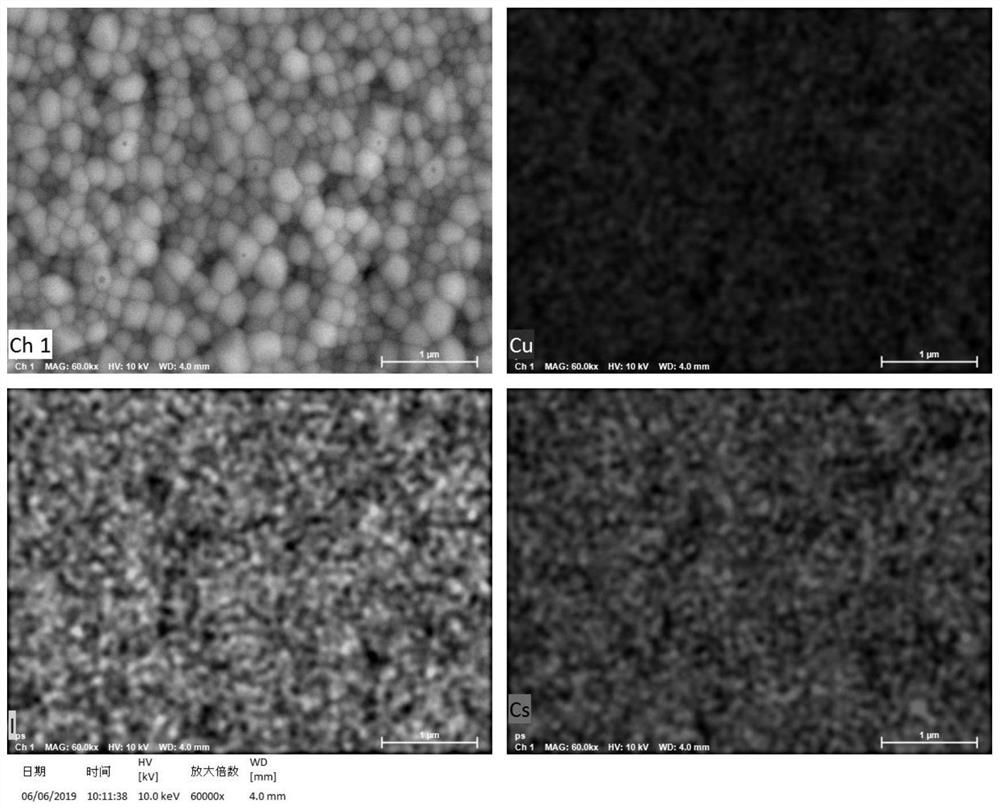

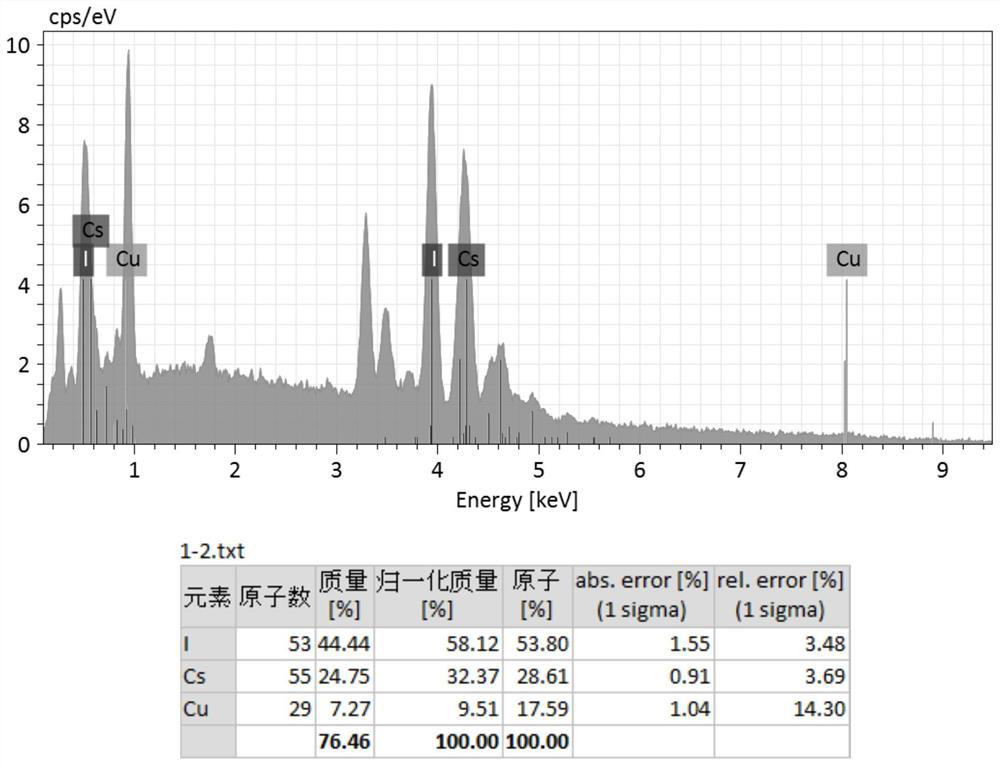

[0035] This embodiment provides a CS 3 Cu 2 I 5 The preparation method of the film, the specific steps are as follows:

[0036] 1) In the mixed solvent of CSI: 469 mg, CuI: 229 mg in DMF and DMSO, wherein DMF is 800 μl, DMSO is 200 μl, and heating is stirred at 60 ° C for 1 hour predecessor solution will completely dissolve;

[0037] 2) Separate the ITO glass by detergent, deionized water, acetone, alcohol, and isopropanol for 30 minutes, then Treatment of UV ozone treatment after 30 minutes;

[0038] 3) 60 μl of dissolved pre-fluid droplets with pipette is added to the center position of ITO glass, and after the predeflow flu flu flu flu flu flu flu flu flu flus is completely released, the spin coating is started, and the spin coating is 1000 transcothaute. The spin coating time is 15 seconds, the second stage spin coating speed is 4000 revolutions, and the spin coating time is 30 seconds, and at the last 5 seconds of the second stage, 100 μL of methyl acetate is rapidly added to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com