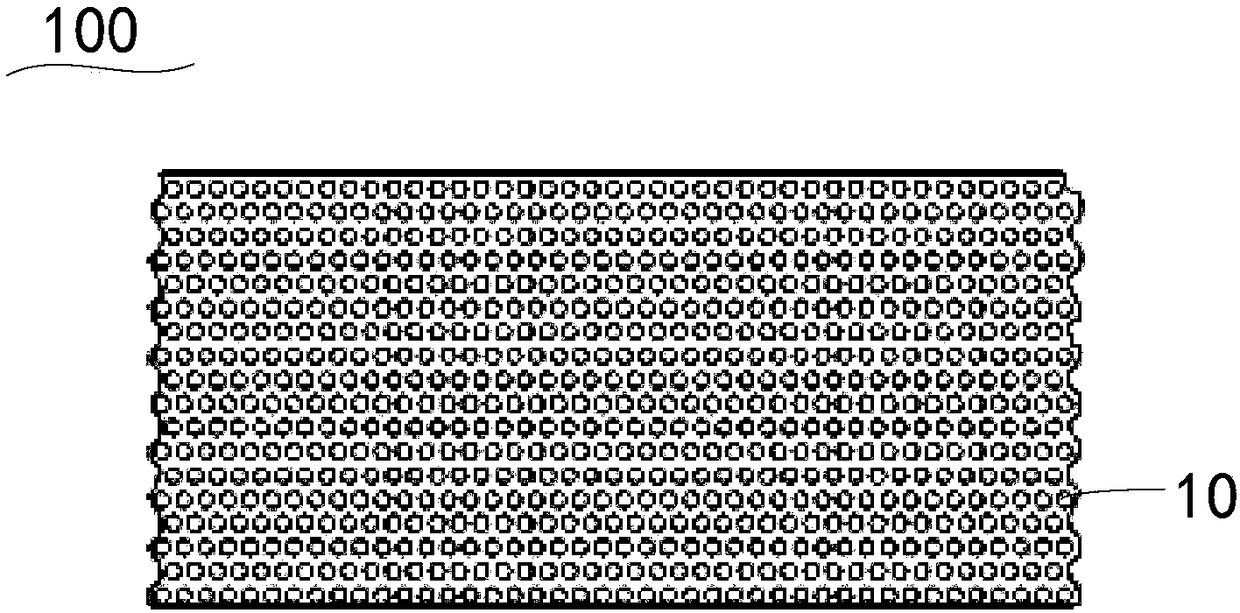

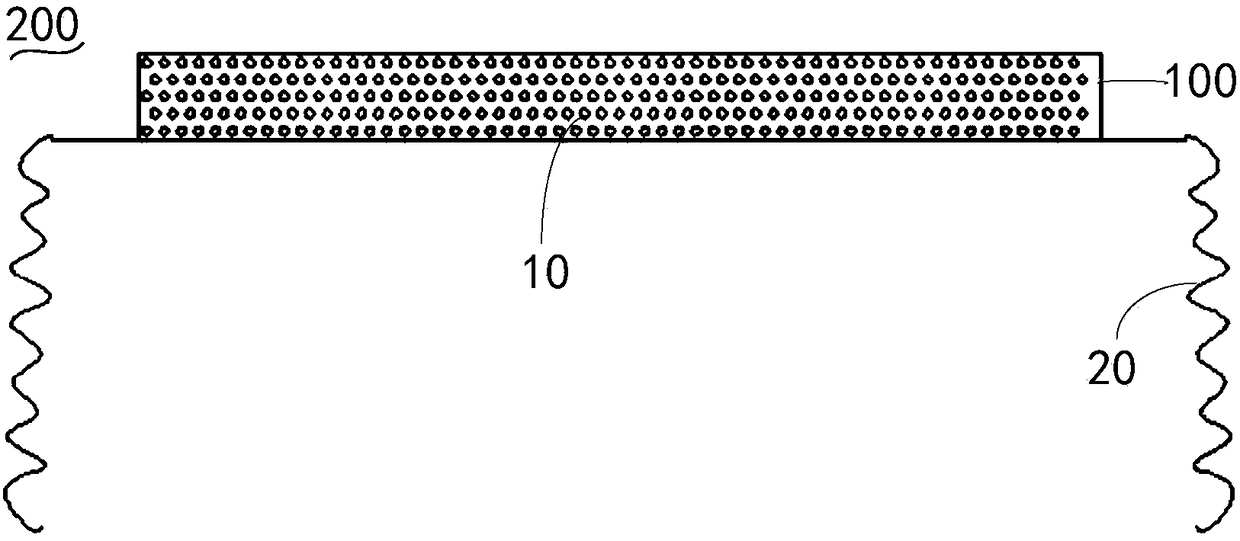

Preparation method of silicon carbon vibration diaphragm, carbon vibration diaphragm and acoustical unit with vibration diaphragm

A silicone diaphragm and silicon carbon technology, applied in electrical components, sensors, etc., can solve problems such as poor audio performance, and achieve the effects of small impact, good elasticity and rigidity, and convenient molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Such as Figure 4 As shown, the preparation method of the silicon carbon diaphragm comprises the following steps:

[0031] S1: Preparation of carbonaceous diaphragm;

[0032] The preparation of the carbonaceous diaphragm specifically includes: providing a precursor resin and a thin film.

[0033] The precursor resin has a predetermined concentration and viscosity, and the precursor resin is one or more combinations of phenolic resin, polyurethane resin, furan resin, silicone resin, unsaturated polyester, basic phenolic resin, and epoxy resin things.

[0034] The precursor resin is a silicon-containing resin complex, and the resin complex is one of silicone resin, silica sol, silica gel, silica gel, silane, and silicon micropowder, wherein the silicon content is 0.01%-100% , the preferred silicon content in this embodiment is 10-50%.

[0035] The film is one of polyethylene, polycarbonate, polyethylene terephthalate, polystyrene, polyetheretherketone, polyimide, liqu...

Embodiment 1

[0061] Mix the silane and the polyurethane resin evenly to obtain the precursor resin, especially, control the silicon content to 14%. The polyurethane precursor resin is evenly coated on the polyethylene terephthalate film containing the release agent through a series of cast roll film equipment, and the thickness of the polyurethane precursor resin on the film is controlled to be 0.05mm . Then the control film loaded with the polyurethane precursor resin passes through a metal box containing hot air, in particular, the temperature of the hot air is controlled to be 75° C., and the film advance speed is 5 m / min. After a predetermined temperature treatment, the coated precursor resin is covered with a polyethylene terephthalate film containing a release agent. It was set at 150° C. under a pressure of 21 MPa to obtain a precursor resin film. The precursor resin film is mechanically cut into films of predetermined shape.

[0062] The aforementioned diaphragm cut into a prede...

Embodiment 2

[0068] The precursor resin is obtained by uniformly mixing the silica gel and the phenolic resin in a predetermined ratio, especially controlling the silicon content to 11%. The phenolic resin is uniformly coated on the polyethylene terephthalate film containing a release agent through a device containing a series of casting rolls, and the thickness of the polyurethane precursor resin on the film is controlled to be 0.08mm. Then the control film loaded with the phenolic resin precursor resin passes through a metal box containing hot air, in particular, the temperature of the hot air is controlled to be 90° C., and the film advance speed is 7 m / min. After a predetermined temperature treatment, the coated precursor resin is covered with a polyethylene terephthalate film containing a release agent. It was set at 157° C. under a pressure of 15.5 MPa to obtain a precursor resin film. The precursor resin film is mechanically cut into films of predetermined shape.

[0069] The afor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com