A kind of mixed weaving bamboo mat and its processing technology

A bamboo mat and mixed weaving technology, applied in the field of bamboo mat manufacturing, can solve the problems of low comfort, poor comfort, and hard texture of bamboo mats, and achieve the effects of high comfort, good technical support, and soft texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

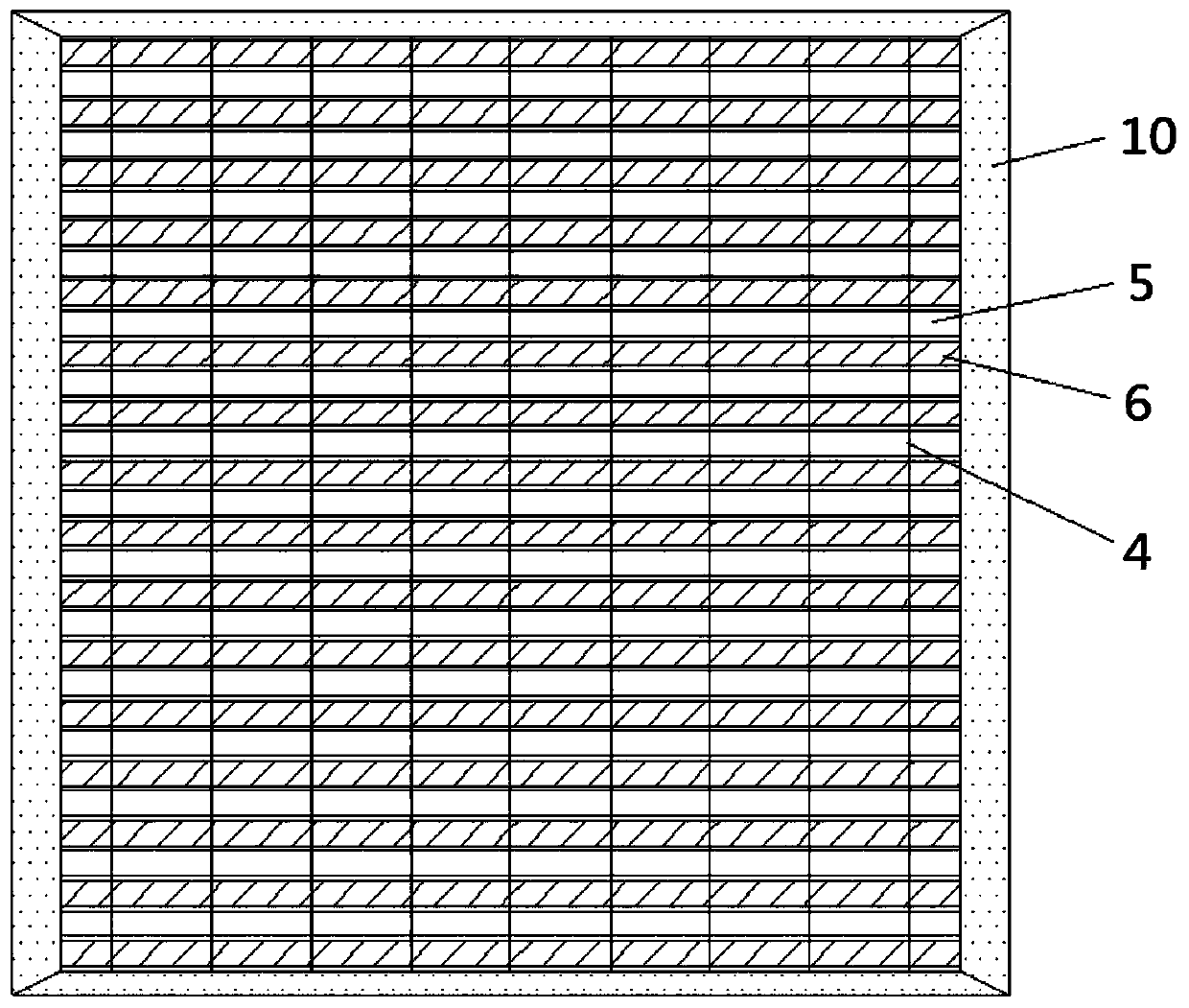

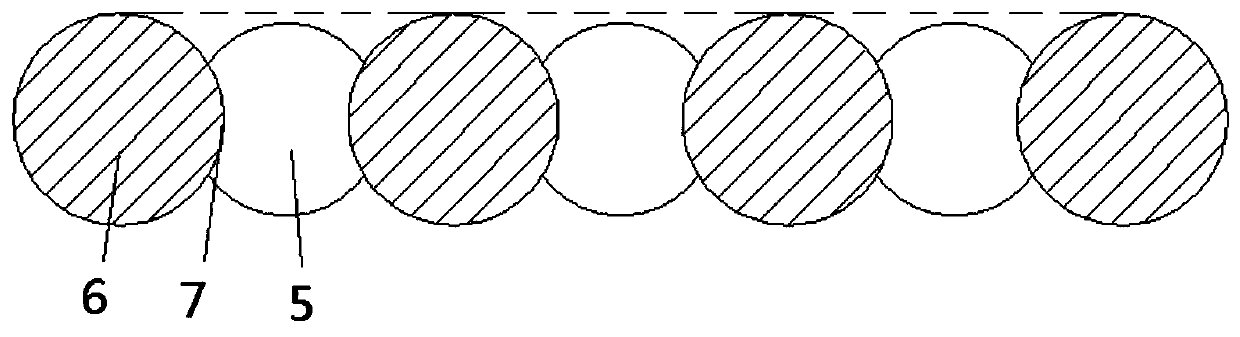

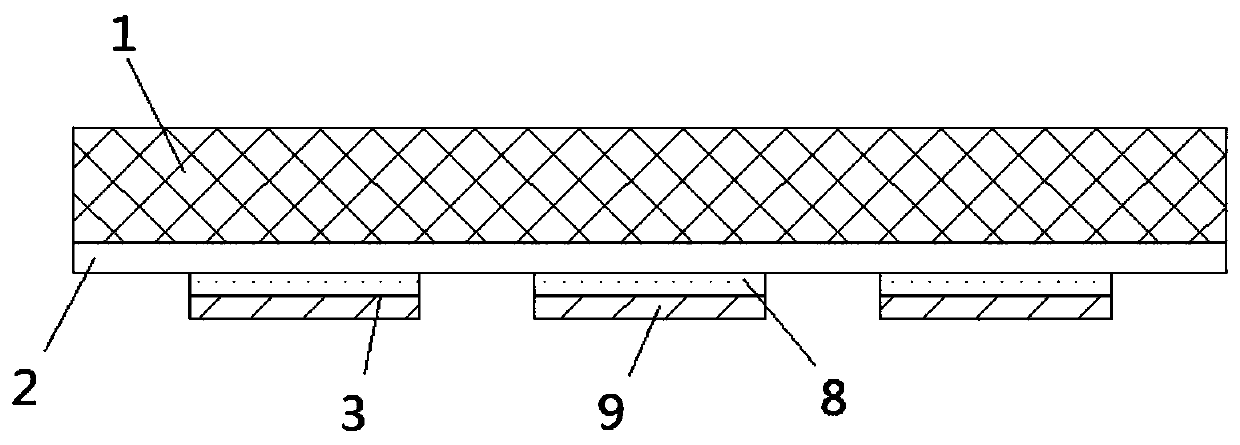

[0033] Embodiment: a kind of mixed weaving bamboo mat, structure such as Figures 1 to 4 As shown, it includes a mixed-woven bamboo mat layer 1, and gauze 2 is arranged below the mixed-woven bamboo mat layer 1, and an anti-slip strip 3 is connected to the gauze; the mixed-woven bamboo mat layer 1 is a weaving structure of warp and weft, wherein It is a chemical fiber line 4, and the weft is formed by adjacent intervals between bamboo strips 5 and rattan strips 6, and the surface of the bamboo strips 5 and rattan strips 6 is provided with an arc-shaped concave 7; the cross-section of the rattan strips 6 is wide and high. Greater than the section width and height of the bamboo strip 5.

[0034] The anti-slip strip 3 includes a silica gel strip 8, and a rubber strip 9 is arranged below the silica gel strip 8.

[0035] The surroundings of the mixed-woven bamboo mat layer 1 are provided with hemming 10 .

[0036] A kind of processing technology that realizes aforementioned mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com