Bonded boron carbide round pipe cutting and end face grinding equipment

A technology of face grinding and boron carbide, which is applied in the direction of grinding/polishing equipment, stone processing equipment, grinding workpiece support, etc., can solve the problems of splashing polluted air, difficult clamping dust, etc., to overcome dust splash polluting air, The effect of compact structure design and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will describe in detail with reference to the accompanying drawings in conjunction with the embodiments, so as to further explain the technical features and advantages of the present invention.

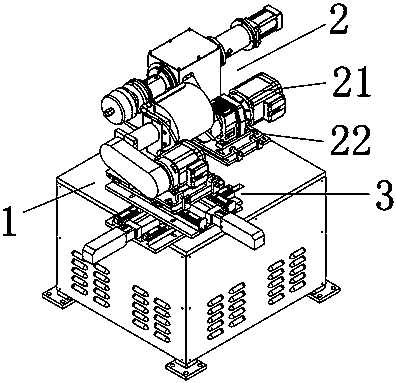

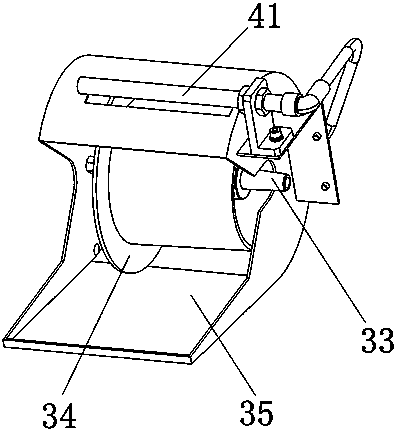

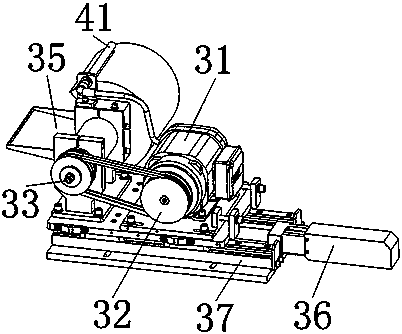

[0027] Such as Figure 1-10 As shown, a kind of bonded boron carbide round tube cutting and end grinding equipment of the present invention includes a workbench 1, an inner support pipe rotating mechanism 2 and a cutting mechanism 3 installed on the workbench 1, and the cutting mechanism 3 is provided with Circulating cooling system, the internal support pipeline rotation mechanism 2 includes an internal support structure 25 for fixing the pipeline to be processed and a first transmission mechanism 23 for driving the rotation of the internal support structure 25, the first transmission mechanism 23 is a chain sprocket transmission mechanism Or a belt transmission mechanism, the inner support structure 25 is connected to the cylinder 26 to realize the clamping and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com