Environment-friendly glass fiber reinforced plastic oil separation tank

A glass fiber reinforced plastic, environmentally friendly technology, applied in the direction of grease/oily substance/float removal device, water/sewage treatment, liquid separation, etc., can solve the problems of prolonged labor time, low work efficiency, increased workload, etc. Simple, easy to operate, and the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

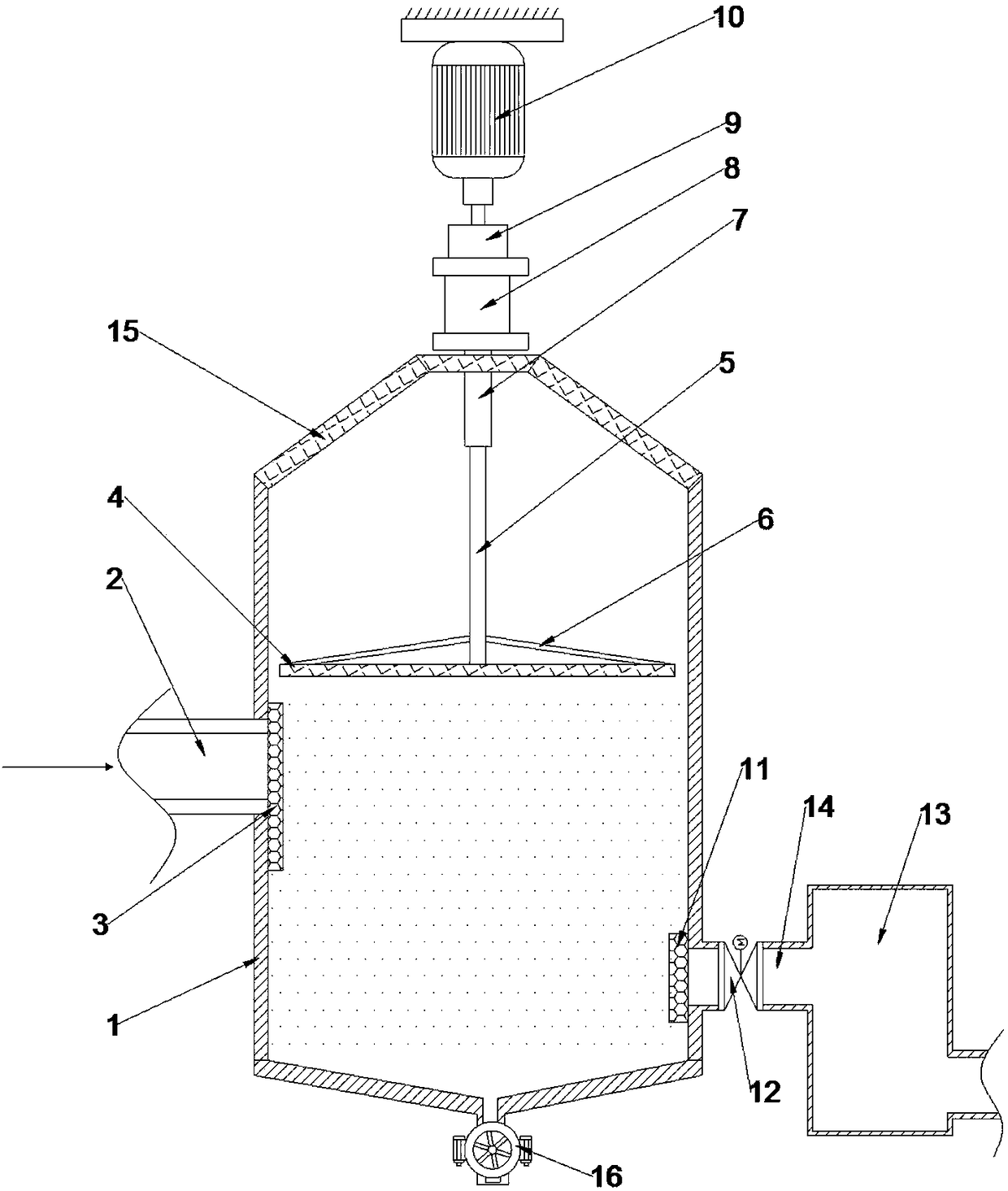

[0031] see figure 1 , an environment-friendly FRP grease trap, comprising a pool body 1 and a frame 6, the pool body 1 is a hollow cylindrical structure, the top of the pool body 1 is equipped with an inverted bowl-shaped second oil-absorbing felt 15, the second The bottom of the edge of the oil-absorbing felt 15 is fitted and fixedly connected with the edge of the top surface of the pool body 1. The side of the pool body 1 is provided with a water inlet pipe 2 communicating with the interior, and above the contact point between the water inlet pipe 2 and the pool body 1, there is a Frame 6, the bottom of the frame 6 is connected with the first oil-absorbing felt 4, the frame 6 is connected with the vertically upward rotating shaft 5, and the end of the rotating shaft 5 away from the frame 6 is connected with a driving mechanism that can make it move up and down. The structure passes through the second oil-absorbing felt 15, and the driving mechanism is connected with the outp...

Embodiment 2

[0034] see figure 1 , an environment-friendly FRP grease trap, comprising a pool body 1 and a frame 6, the pool body 1 is a hollow cylindrical structure, the top of the pool body 1 is equipped with an inverted bowl-shaped second oil-absorbing felt 15, the second The bottom of the edge of the oil-absorbing felt 15 is fitted and fixedly connected with the edge of the top surface of the pool body 1. The side of the pool body 1 is provided with a water inlet pipe 2 communicating with the interior, and above the contact point between the water inlet pipe 2 and the pool body 1, there is a Frame 6, the bottom of the frame 6 is connected with the first oil-absorbing felt 4, the frame 6 is connected with the vertically upward rotating shaft 5, and the end of the rotating shaft 5 away from the frame 6 is connected with a driving mechanism that can make it move up and down. The structure passes through the second oil-absorbing felt 15, and the driving mechanism is connected with the outp...

Embodiment 3

[0038] see figure 1 , an environment-friendly FRP grease trap, comprising a pool body 1 and a frame 6, the pool body 1 is a hollow cylindrical structure, the top of the pool body 1 is equipped with an inverted bowl-shaped second oil-absorbing felt 15, the second The bottom of the edge of the oil-absorbing felt 15 is fitted and fixedly connected with the edge of the top surface of the pool body 1. The side of the pool body 1 is provided with a water inlet pipe 2 communicating with the interior, and above the contact point between the water inlet pipe 2 and the pool body 1, there is a Frame 6, the bottom of the frame 6 is connected with the first oil-absorbing felt 4, the frame 6 is connected with the vertically upward rotating shaft 5, and the end of the rotating shaft 5 away from the frame 6 is connected with a driving mechanism that can make it move up and down. The structure passes through the second oil-absorbing felt 15, and the driving mechanism is connected with the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com