Diversion based biological film waste water integrated treatment process

A technology of treatment process and sewage treatment system, applied in the field of integrated treatment process of drainage biofilm sewage, can solve the problems of unreasonable design, high operation cost, substandard effluent, etc. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

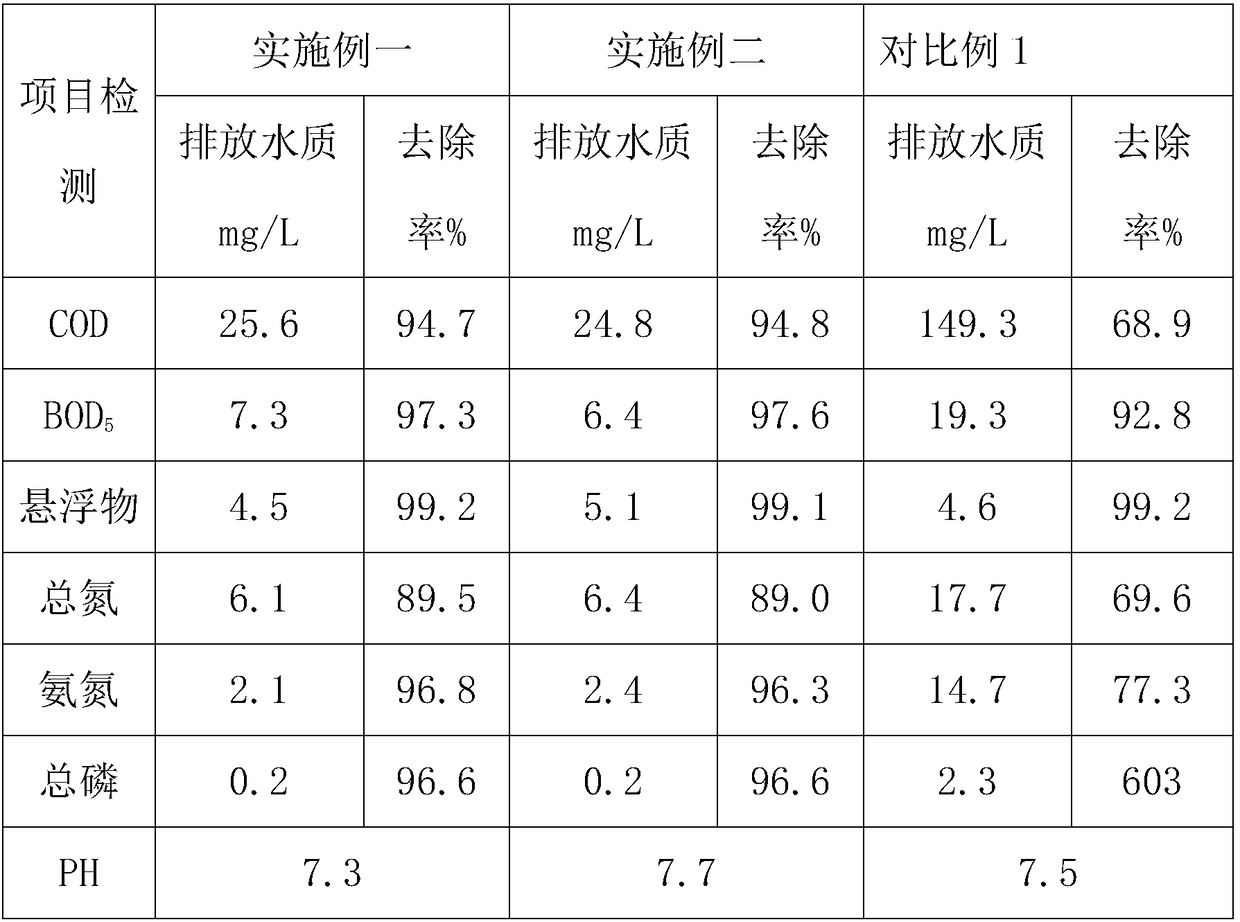

Embodiment 1

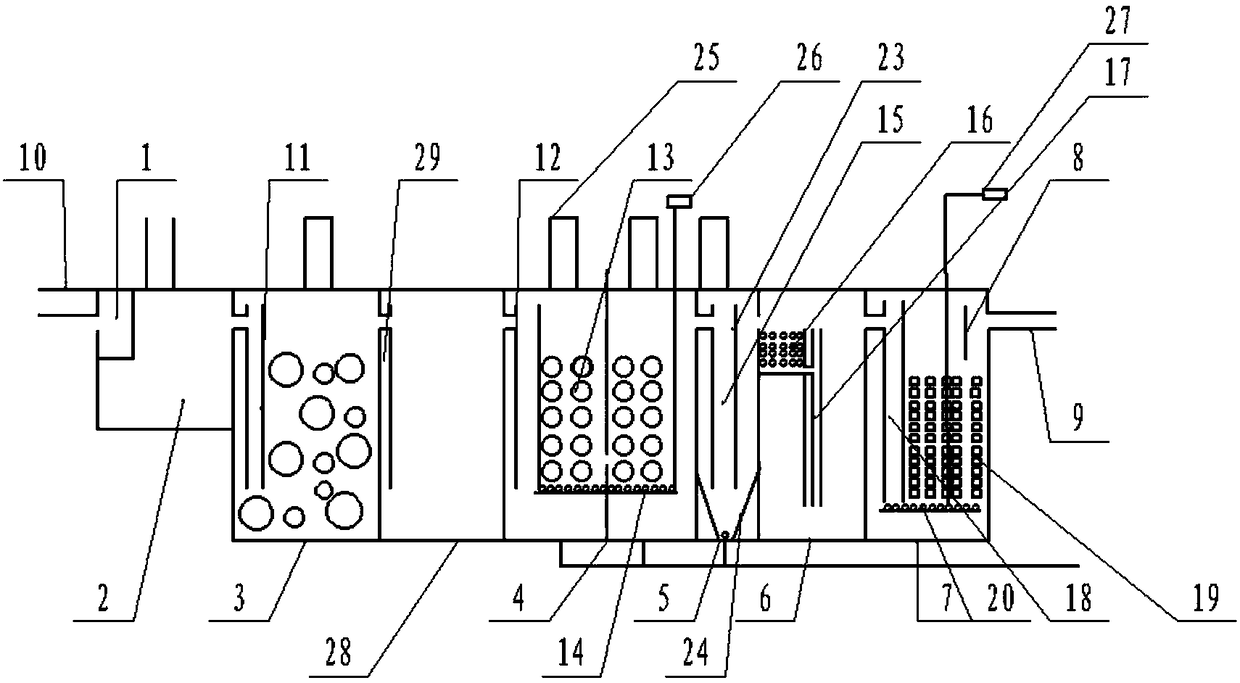

[0039] like figure 1 As shown, a kind of drainage biofilm sewage integrated treatment process that the present invention proposes comprises the following steps:

[0040] S1. Establish drainage biofilm sewage treatment system. The drainage biofilm sewage treatment system includes grid 1, regulating tank 2, anaerobic tank 3, hydrolytic acidification tank 28, secondary aerobic tank 4, sedimentation tank 5, and quick filter tank 6 , ozone tank 7, ultraviolet disinfection pipe 8 and clear water outlet pipe 9, regulating tank 2, anaerobic tank 3, secondary aerobic tank 4, sedimentation tank 5, fast filter tank 6, ozone tank 7, and clear water outlet pipe 9 pass through in turn Pipeline connection; grille 1 is set on the upper corner of the adjustment pool 2, the grille 1 is an electric grille, and the gap between the bars of the grille 1 can be adjusted according to the characteristics of different sewage debris, and the gap between the bars is 16mm to 25mm; The side of the adjustm...

Embodiment 2

[0046] An integrated treatment process for drainage biofilm sewage proposed by the present invention comprises the following steps:

[0047]S1. Establish drainage biofilm sewage treatment system. The drainage biofilm sewage treatment system includes grid 1, regulating tank 2, anaerobic tank 3, hydrolytic acidification tank 28, secondary aerobic tank 4, sedimentation tank 5, and quick filter tank 6 , ozone tank 7, ultraviolet disinfection pipe 8 and clear water outlet pipe 9, regulating tank 2, anaerobic tank 3, secondary aerobic tank 4, sedimentation tank 5, fast filter tank 6, ozone tank 7, and clear water outlet pipe 9 pass through in turn Pipeline connection; grille 1 is set on the upper corner of the adjustment pool 2, and the grille 1 is a manual grille, and the gap between the bars of the grille 1 can be adjusted according to the characteristics of different sewage debris, and the gap between the bars is 16mm to 25mm The side of the adjustment tank 2 provided with the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com