Low temperature-resistant fluororubber and preparation method thereof

A fluororubber and low temperature resistant technology, applied in the field of low temperature resistant fluororubber and its preparation, can solve the problems of poor dispersibility and adhesion performance, achieve remarkable low temperature resistance, improve fluidity and adhesion performance, and improve vulcanization performance and strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

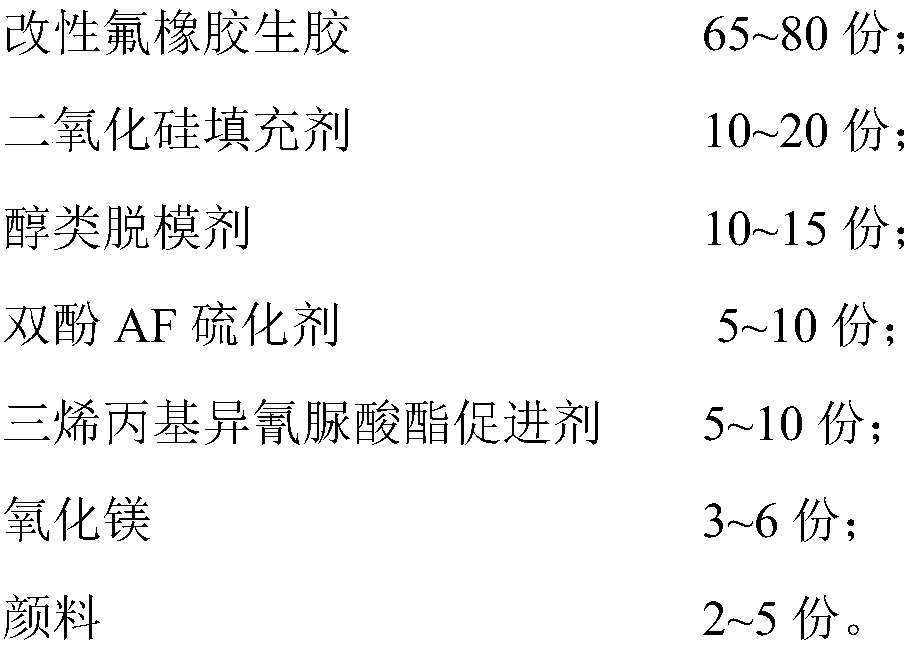

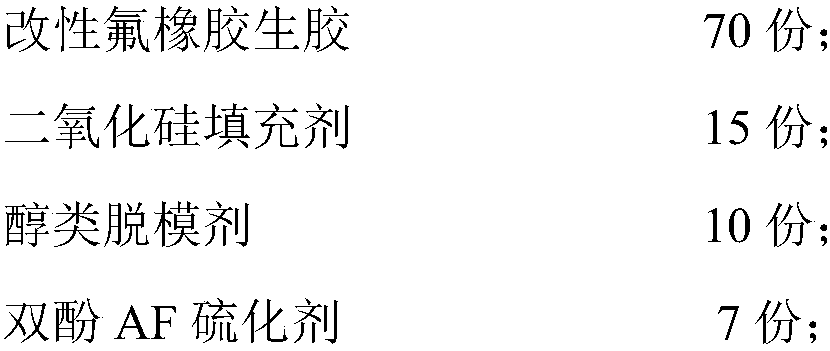

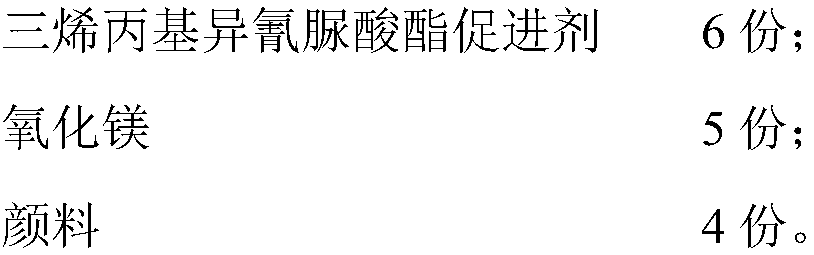

Embodiment 1

[0022] Mix 4 parts of pigment, 5 parts of magnesium oxide, 15 parts of silica filler and 6 parts of triallyl isocyanurate accelerator to obtain mixture A; mix 10 parts of alcohol release agent (WS280) and double Mix 7 parts of phenolic AF vulcanizing agent uniformly to obtain mixture B; finally, add 70 parts of obtained mixture A, mixture B and modified fluororubber raw rubber to water (the amount of water added is 0.5 times the total mass of the material) and stir at 240 ° C, and then Take it out and let it cool naturally.

Embodiment 2

[0024] Mix 2 parts of pigment, 3 parts of magnesium oxide, 10 parts of silica filler and 5 parts of triallyl isocyanurate accelerator to obtain mixture A; mix 15 parts of alcohol release agent (WS280) and double Mix 10 parts of phenolic AF vulcanizing agent uniformly to obtain mixture B; finally, add 80 parts of obtained mixture A, mixture B and modified fluororubber raw rubber to water (the amount of water added is 0.6 times of the total mass of the material) and stir at 250 ° C, and then Take it out and let it cool naturally.

Embodiment 3

[0026] Mix 5 parts of pigment, 6 parts of magnesium oxide, 20 parts of silica filler and 10 parts of triallyl isocyanurate accelerator to obtain mixture A; mix 10 parts of alcohol release agent (WS280) and double Mix 5 parts of phenolic AF vulcanizing agent uniformly to obtain mixture B; finally, add 65 parts of obtained mixture A, mixture B and modified fluororubber raw rubber to water (the amount of water added is 0.3 times of the total mass of the material) and stir evenly at 200 °C, and then Take it out and let it cool naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com