Composition for maintaining stability of residual polymer in polymer flooding produced water, and applications thereof

A technology of composition and polymer, applied in drilling composition, mining wastewater treatment, water/sewage treatment and other directions, can solve problems such as affecting stability, achieve enhanced stability, maintain good micropore passage, and facilitate The effect of redistribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Composition formula 1: the components in the composition are calculated by mass concentration: OP-10 with a mass concentration of 50 mg / L is used as an emulsified oil influence inhibitor, and carboxymethyl cellulose sodium with a mass concentration of 100 mg / L is used as a solid suspension Impact inhibitor, and the disodium oxalate tetraacetate that mass concentration is 50mg / L affects inhibitor as metal ion.

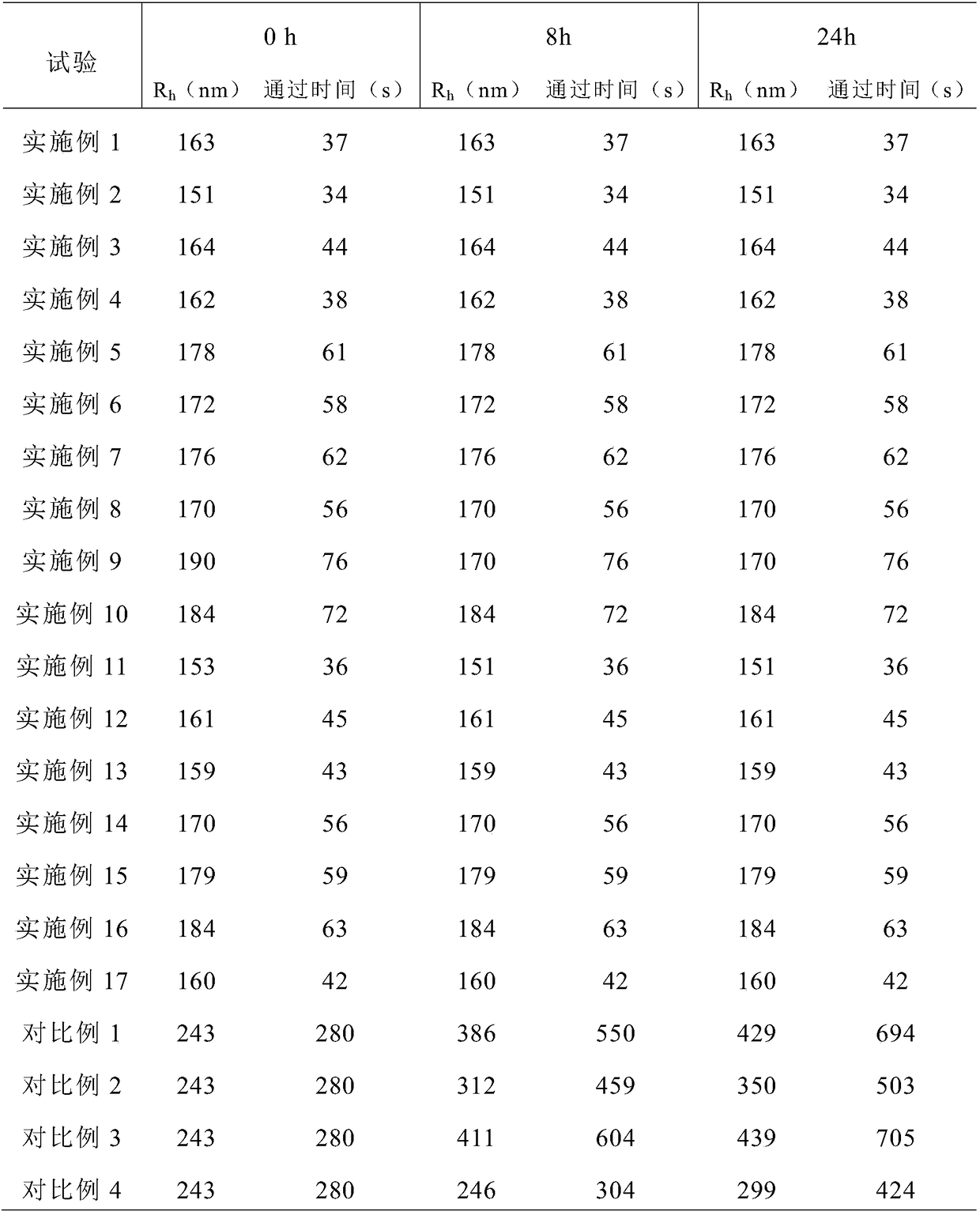

[0027] When the residual polymer concentration is 150mg / L, the emulsified oil concentration is 200mg / L, and the solid suspension concentration is 25mg / L, Fe 2+ The concentration is 3mg / L, Fe 3+ Add the composition formula 1 to the produced water of polymer flooding with a concentration of 4mg / L, and monitor the hydrodynamic radius R of the residual polymer at 0h, 8h, and 24h respectively h , the time t required for micropores to pass through, and the results are shown in Table 1 below.

Embodiment 2

[0029] Composition formula 2: the components in the composition are calculated by mass concentration: OP-10 with a mass concentration of 100 mg / L is used as an emulsified oil influence inhibitor, and carboxymethyl cellulose sodium with a mass concentration of 100 mg / L is used as a solid suspension Impact inhibitor, and the disodium oxalate tetraacetate that mass concentration is 50mg / L affects inhibitor as metal ion.

[0030] In the polymer flooding produced water under the same conditions as in Example 1, add composition formula 2, and monitor respectively 0h, 8h, and the hydrodynamic radius R of the residual polymer at the time of 24h h , the time t required for micropores to pass through, and the results are shown in Table 1 below.

Embodiment 3

[0032] Composition formula 3: the components in the composition are calculated by mass concentration: OP-10 with a mass concentration of 100 mg / L is used as an emulsified oil influence inhibitor, and carboxymethyl cellulose sodium with a mass concentration of 150 mg / L is used as a solid suspension Impact inhibitor, and the disodium oxalate tetraacetate that mass concentration is 50mg / L affects inhibitor as metal ion.

[0033] In the polymer flooding produced water under the same conditions as in Example 1, add composition formula 3, and monitor 0h, 8h, and the hydrodynamic radius R of the residual polymer at 24h h , the time t required for micropores to pass through, and the results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com