Four-stage integrated method and device for impurity removal of oilfield associated gas

An integrated technology of oilfield associated gas, applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of unsatisfactory impurity removal effect of oilfield associated gas, many impurities in the product gas, and acidity of the gas, so as to achieve convenient sampling and treatment effect. Good, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

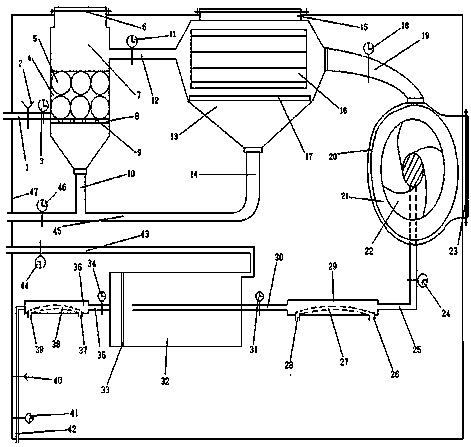

[0011] When processing raw gas associated with oilfield gas, the raw gas of associated gas enters the device from the raw gas inlet pipe (1), and enters the deacidification chamber (7) through the stop valve No. 1 (2) and the flow meter No. 1 (3). No. (2) can close the raw gas inlet pipe (1); the associated gas raw gas is deacidified by the slaked lime block (5) in the reaction box (4) in the deacidification chamber (7), and the generated water passes through the leakage The leakage hole (9) on the plate (8) enters the drain pipe (10) of the deacidification chamber, and finally enters the main drain pipe (45). left side. When the deacidification chamber (7) and its internal components fail, the inspection valve No. 1 (6) can be opened for maintenance; the gas after deacidification enters the gravity settlement through the connecting pipe No. 1 (12) and the flow meter No. 2 (11) chamber (13), flow meter No. 2 (11) can record the fluid flow entering the gravity settling chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com