Heat treatment technology of steel-grade oil casing

A technology of petroleum casing and steel pipe, which is applied in the field of heat treatment of steel grade petroleum casing, which can solve the problems of insufficient mechanical properties, poor bending effect, and poor hardenability of steel pipes, etc., so as to improve mechanical properties and improve hardenability The effect of reducing the critical cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

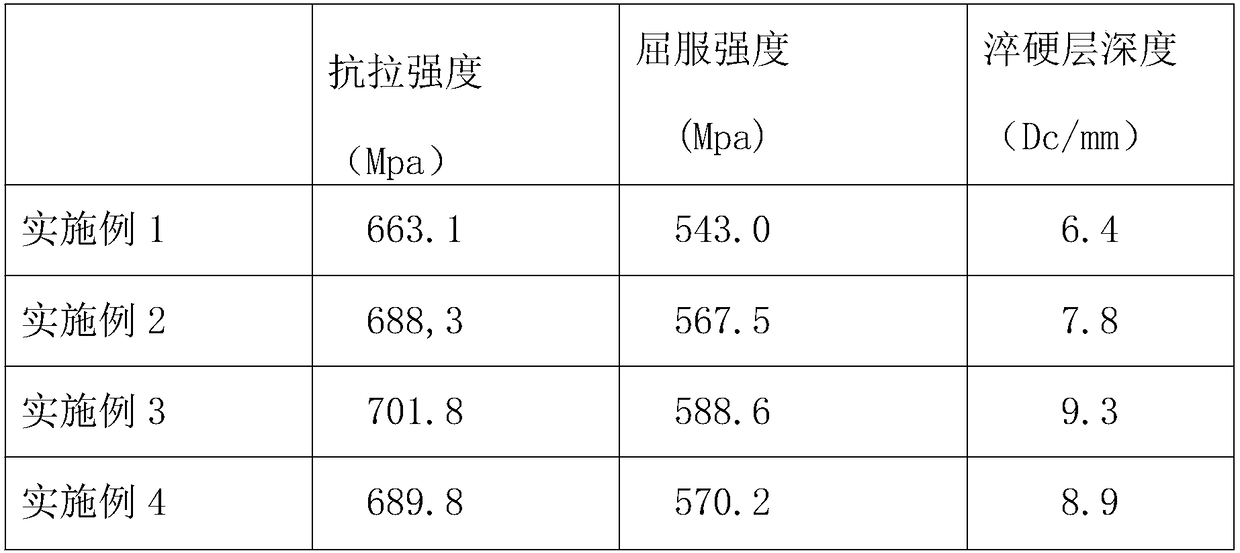

Embodiment 1

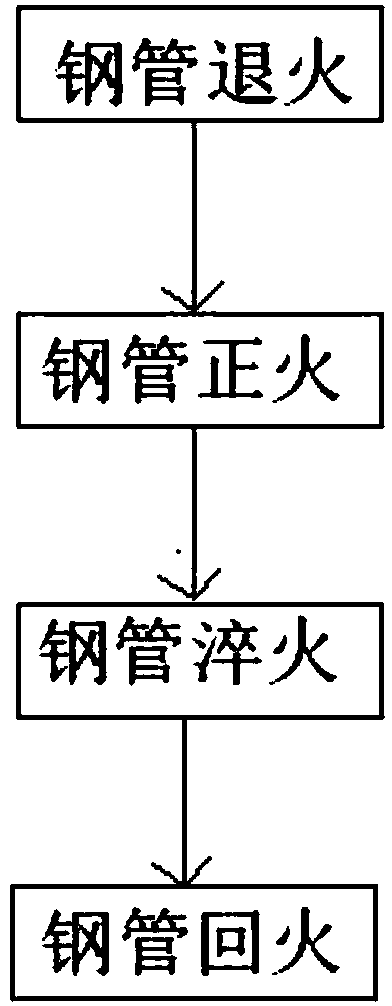

[0046] The invention discloses a heat treatment process for steel-grade petroleum casing. The specific steps are as follows:

[0047] (1) Steel pipe annealing: heat the steel pipe to 700°C, keep it warm and cool it down;

[0048] (2) Steel tube normalizing: heat the cooled steel tube to 750°C, keep it warm and cool it down;

[0049] (3) Steel pipe quenching: heating the cooled steel pipe to 700°C, cooling rapidly after heat preservation to obtain martensite;

[0050] (4) Steel pipe tempering: heat the martensitic steel pipe to 700°C, temper for 1.5 hours, keep warm and then cool.

[0051] The cooling in the step (1)-step (4) is carried out alternately by means of oil cooling and natural cooling in the air.

[0052] The heat preservation time after tempering in the step (4) is 160 minutes, and the temperature during heat preservation is 500°C.

[0053] In the step (4), when the steel pipe is tempered, the furnace is filled with argon.

[0054] The cooling temperature in the...

Embodiment 2

[0056] The invention discloses a heat treatment process for steel-grade petroleum casing. The specific steps are as follows:

[0057] (1) Steel pipe annealing: heat the steel pipe to 700°C, keep it warm and cool it down;

[0058] (2) Steel tube normalizing: heat the cooled steel tube to 750°C, keep it warm and cool it down;

[0059] (3) Steel pipe quenching: heating the cooled steel pipe to 700°C, cooling rapidly after heat preservation to obtain martensite;

[0060] (4) Steel pipe tempering: heat the martensitic steel pipe to 700°C, temper for 1.5 hours, keep warm and then cool.

[0061]The cooling in the step (1)-step (4) is carried out alternately by means of oil cooling and natural cooling in the air.

[0062] In the step (3), 125 g of manganese and boron are added during the first half of the steel pipe quenching, and 175 g of molybdenum are added during the second half of the steel pipe quenching.

[0063] The heat preservation time after tempering in the step (4) is ...

Embodiment 3

[0067] The invention discloses a heat treatment process for steel-grade petroleum casing. The specific steps are as follows:

[0068] (1) Steel pipe annealing: heat the steel pipe to 700°C, keep it warm and cool it down;

[0069] (2) Steel tube normalizing: heat the cooled steel tube to 750°C, keep it warm and cool it down;

[0070] (3) Steel pipe quenching: heating the cooled steel pipe to 700°C, cooling rapidly after heat preservation to obtain martensite;

[0071] (4) Steel pipe tempering: heat the martensitic steel pipe to 700°C, temper for 1.5 hours, keep warm and then cool.

[0072] The cooling in the step (1), step (2) and step (4) adopts two modes of oil cooling and natural cooling in the air alternately, in the step (3), the cooling pipeline is filled with liquid nitrogen, and the liquid nitrogen is used for cooling Way.

[0073] In the step (3), 125 g of manganese is added during the first half of steel pipe quenching, and 175 g of molybdenum is added during the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com