An assembled monolithic concealed beam hollow two-way floor and its assembly method

An assembly method and integrated technology, applied in the direction of floors, buildings, building components, etc., can solve the problems of inability to give full play to the tensile capacity of distributed steel bars, great differences in mechanical properties, and difficulty in transportation and hoisting. The effect of welding work, improving thermal insulation and sound insulation, and improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

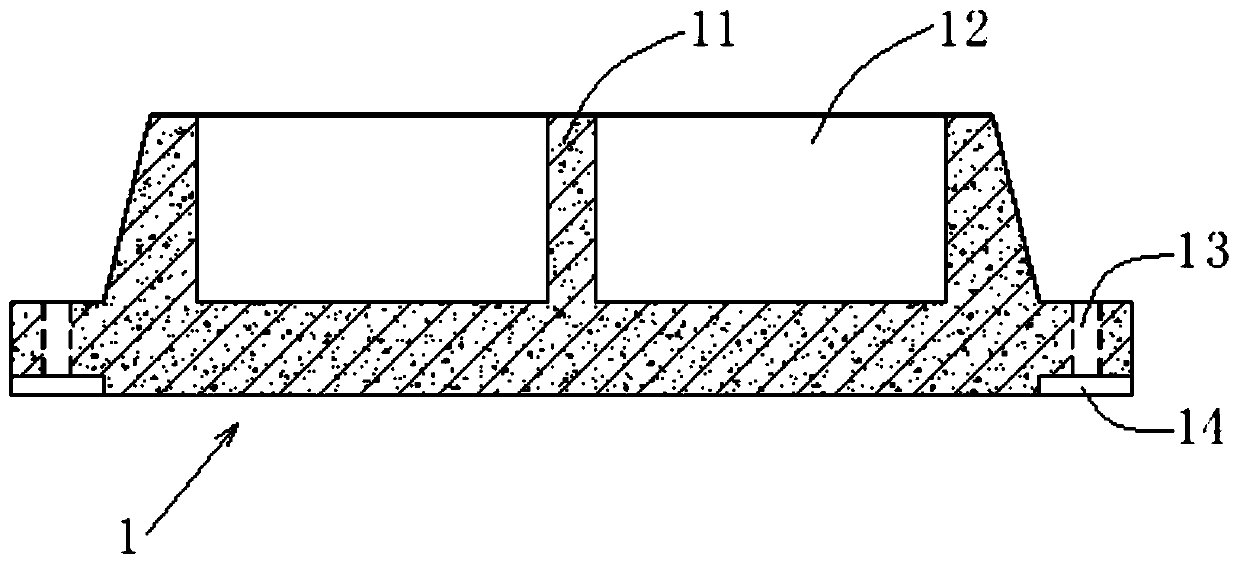

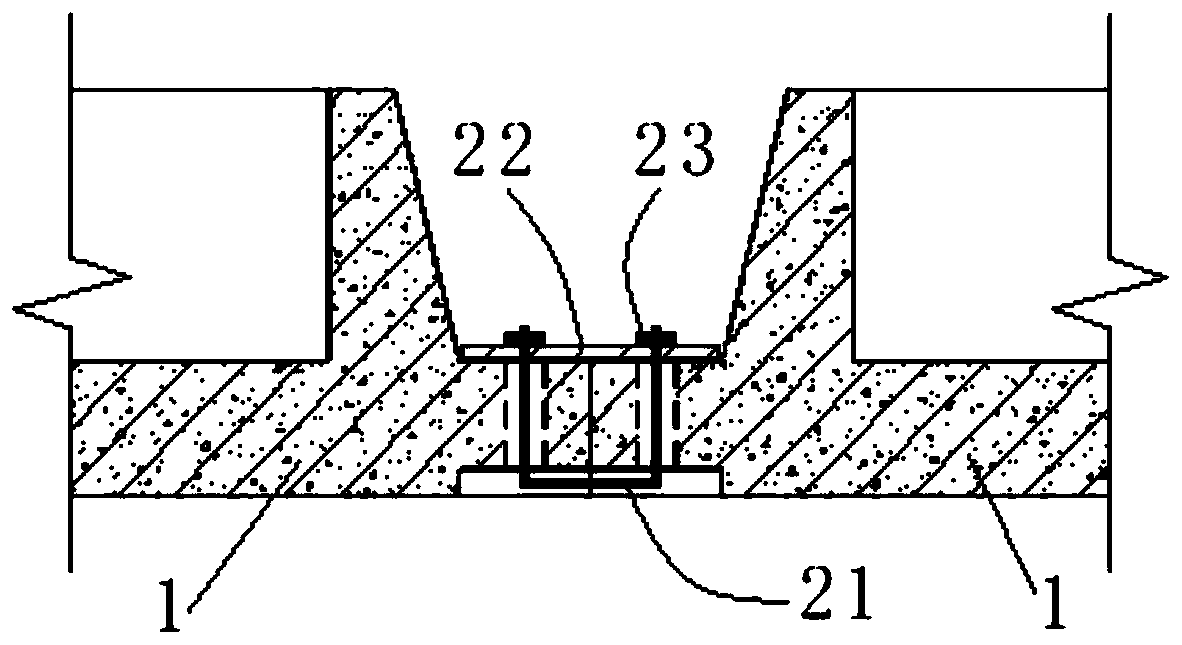

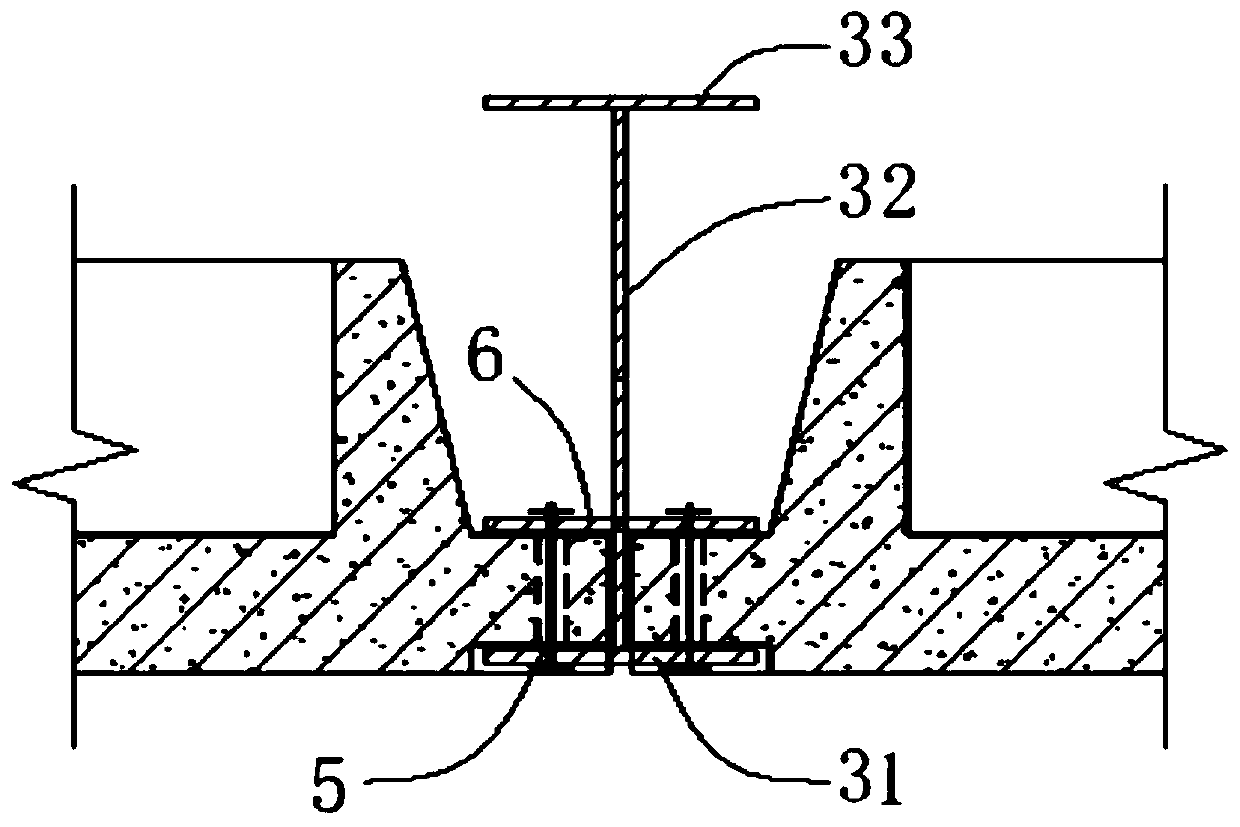

[0034] An assembled integral concealed beam hollow two-way floor of the present invention comprises a prefabricated slab 1 arranged in the hollow of a two-way rib box, a honeycomb steel beam 3 as a main beam or a secondary beam, and a U-shaped hoop 2 connected by bolts 5, and cast-in-place concrete4. The surface of one side of the prefabricated panel 1 is integrally provided with a number of boxes 12 arranged in a matrix, and the other side surface is provided with connecting grooves 14 around; the connecting groove 14 is provided with reserved bolt holes 13 penetrating through the prefabricated panel 1; honeycomb steel The beam 3 is used for the main beam and the secondary beam of the steel structure of the floor; the prefabricated slab 1 is fixed between the secondary beams or between the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com