Rock breaking speed-increasing tool with hammer rod reciprocating self-impact structure

A hammer rod and rock breaking technology, applied in the direction of impact drilling, reciprocating drilling rig, drilling equipment, etc., can solve the problems of low drilling efficiency in highly abrasive formations, inability to design multiple punches at the same time, and short life of the drill bit, etc. Achieve the effect of improving rock breaking efficiency, ensuring service life and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

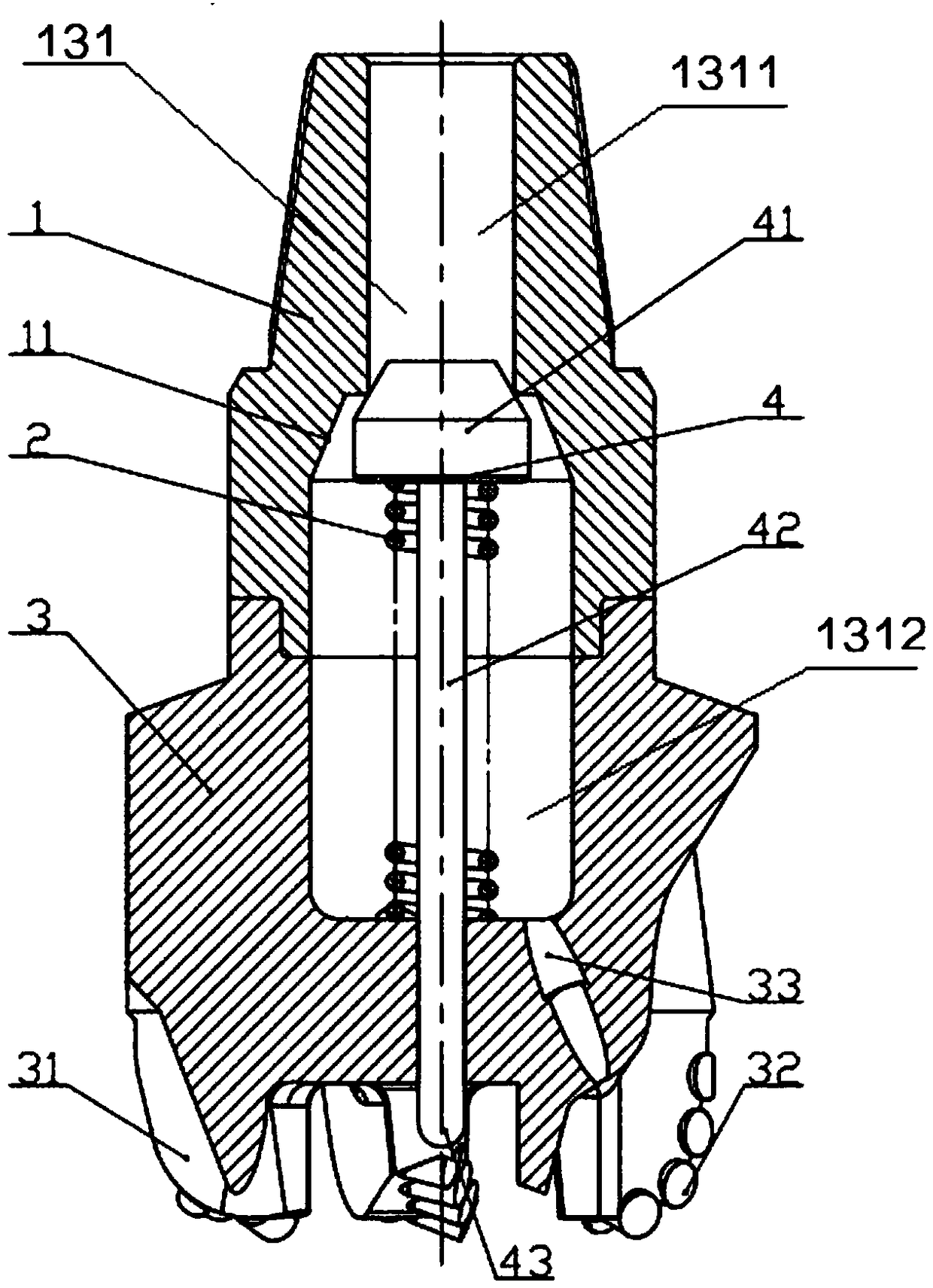

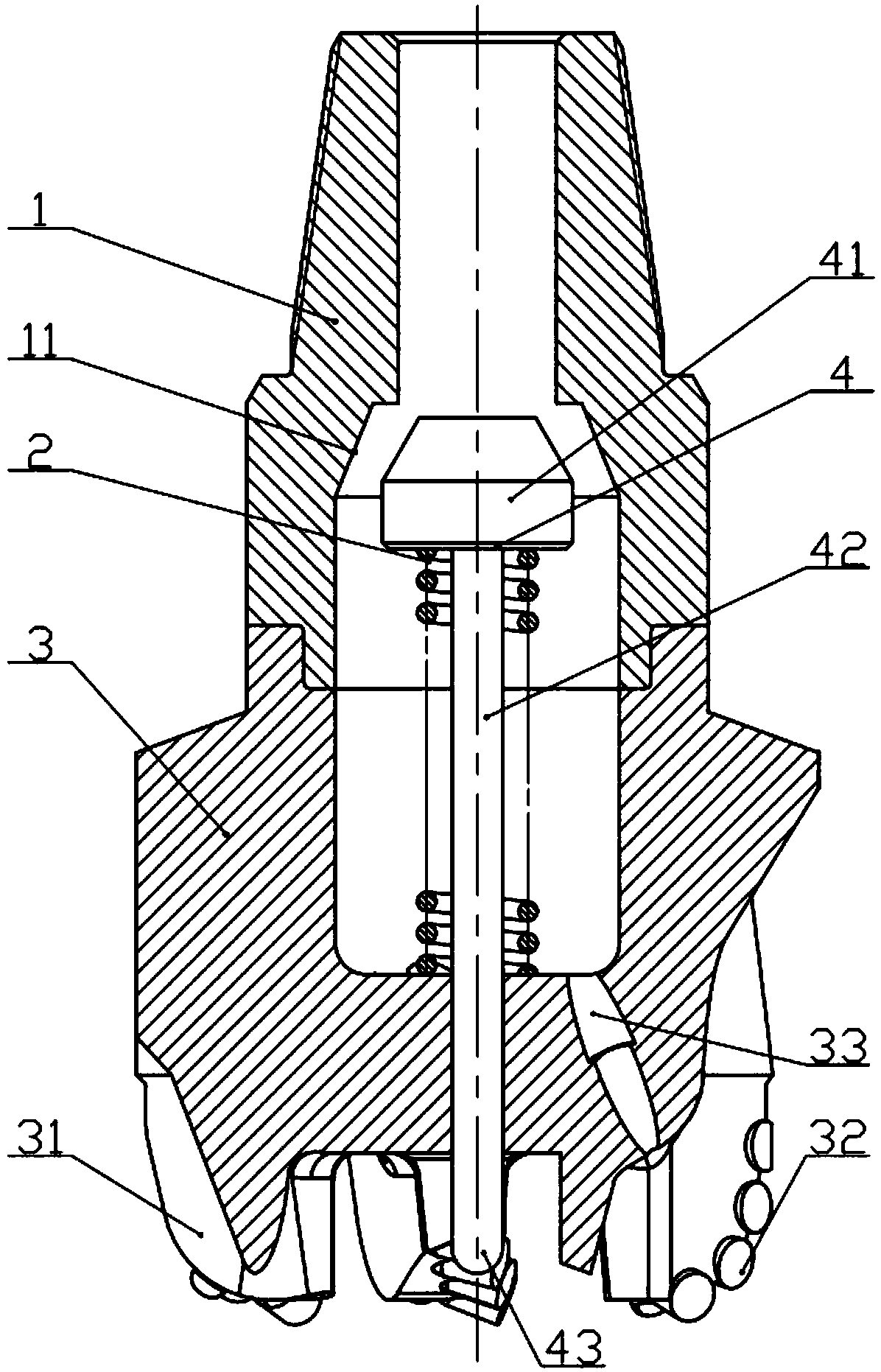

[0042] In this example, if Figure 1~3As shown in and 6, a rock-breaking speed-increasing tool with a hammer shaft reciprocating self-impacting structure includes a joint 1 and a drill body 3. A fixed cutting structure 31 is arranged at the lower end of the drill body 3, and a fixed cutting structure 31 is arranged on the fixed cutting structure 31. Teeth 32, the inner cavity of the drill bit body 3 communicates with the outside world through the water hole 33 inside the fixed cutting structure 31; the joint 1 is connected with the drill bit body 3 to form an inner cavity, and the inner cavity includes a main cavity 131, the bottom diameter of the cylindrical liquid inlet channel 1311 on the upper part of the main cavity 131 and the bottom surface of the lower part are larger than the coaxial cylindrical piston chamber 1312 of the liquid inlet channel 1311, the connection between the liquid inlet channel 1311 and the piston chamber 1312 A valve seat 11 with a variable cross-se...

Embodiment 2

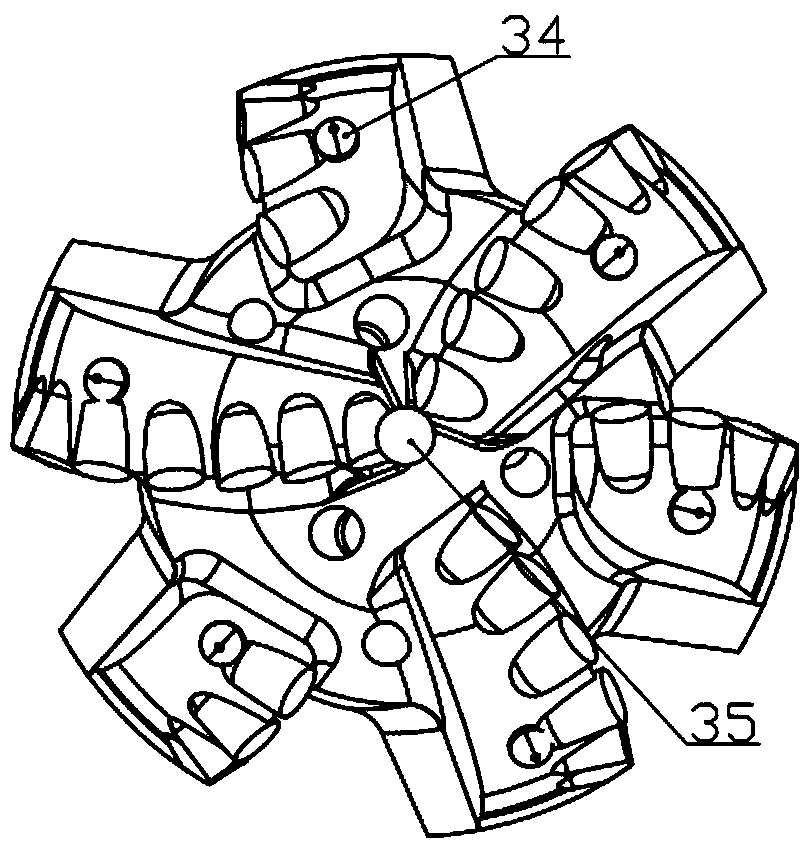

[0051] In this example, if Figure 1~4 As shown in and 6, a rock-breaking speed-up tool with a hammer shaft reciprocating self-impact structure, as another solution, the cross section of the hammer shaft slideway 35 is a regular polygon, and correspondingly in the hammer shaft slideway 35 The hammer rod 42 of motion is a corresponding regular polygon, and now the piston hammer 4 rotates with the drill bit, and the impact rock effect is better. The rest of the technical features are the same as those in Embodiment 1.

Embodiment 3

[0053] In this example, if Figure 5 , 6 As shown in , 8, a rock-breaking speed-up tool with a hammer rod reciprocating self-impact structure, a valve-type impactor is arranged in the main cavity 131, and the valve-type impactor includes a piston hammer 4 and 1 root spring 2, the piston hammer 4 includes a hammer head 41 and two hammer rods 42; 42 passes through two hammer rod slideways 35 successively from bottom to top, and is connected with the lower end of the hammer head 41 . One hammer head 41 and two hammer rods 42 are set in this program. Due to the simplicity of the structure, two hammer rods are designed in the limited space of the drill body 3 at the same time. The axial center line of the drill bit body 3 is evenly distributed in the circumferential direction, and is staggered from the water hole 33 inside the drill bit body 3, so that the force on the hammer shaft 42 is uniform, and the balance of the drill bit is maintained when the impact force is applied. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Middle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com