Leafy vegetable vacuum dehydrating precooling device and precooling method

A vacuum dehydration and pre-cooling technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of vegetable nutritional loss, equipment investment and energy consumption, and reduce equipment drying efficiency. High drying efficiency, effect of maintaining nutritional value and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

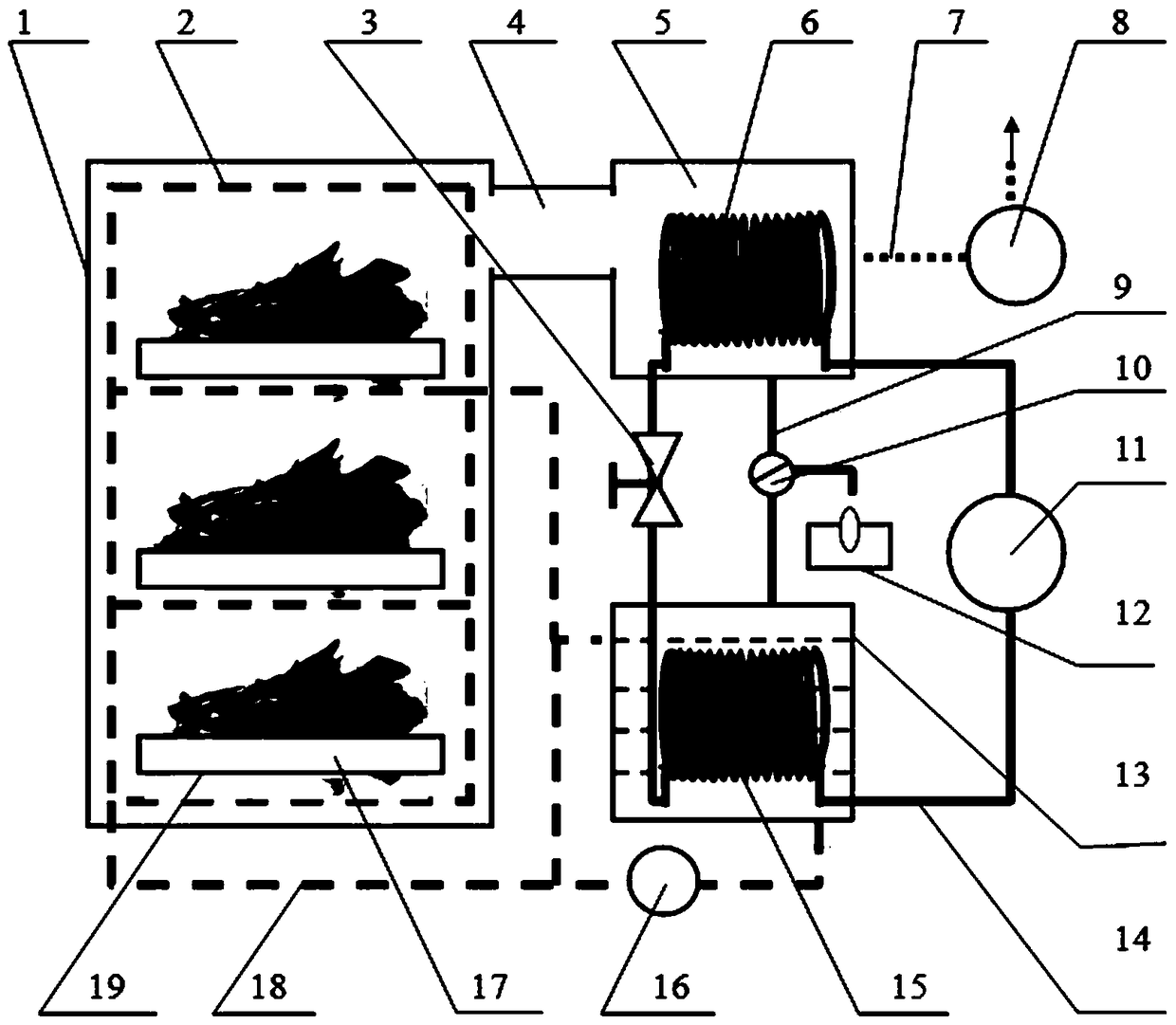

[0022] Such as figure 1 As shown, the leaf vegetable vacuum dehydration and precooling device provided by the present invention includes a dehydration and precooling vacuum box, a vacuum system, a refrigeration system and a heating system. Wherein the dehydration precooling vacuum box includes a box body 1 and a sealing door 2, and the sealing door 2 is used to seal the box body 1. The vacuum system includes a water vapor channel 4, a water vapor capture chamber 5, a vacuum pipeline 7 and a vacuum pump 8; the casing 1 and the water vapor capture chamber 5 are communicated through the water vapor channel 4, and the water vapor capture chamber 5 It is connected to a vacuum pump 8 through a vacuum line 7 .

[0023] The refrigeration system includes an evaporator 6 , a condenser 15 , a refrigeration pipeline 14 , a compressor 11 and an expansion valve 3 ; the heating system includes a water tank 13 , a circulating water pump 16 and a heating pipeline 18 . The evaporator 6 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com