Constant-temperature constant-humidity environment wear resistant test tank

A constant temperature and humidity, wear-resistant test technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems that the pressure cannot be kept constant, there are differences, and the running speed is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

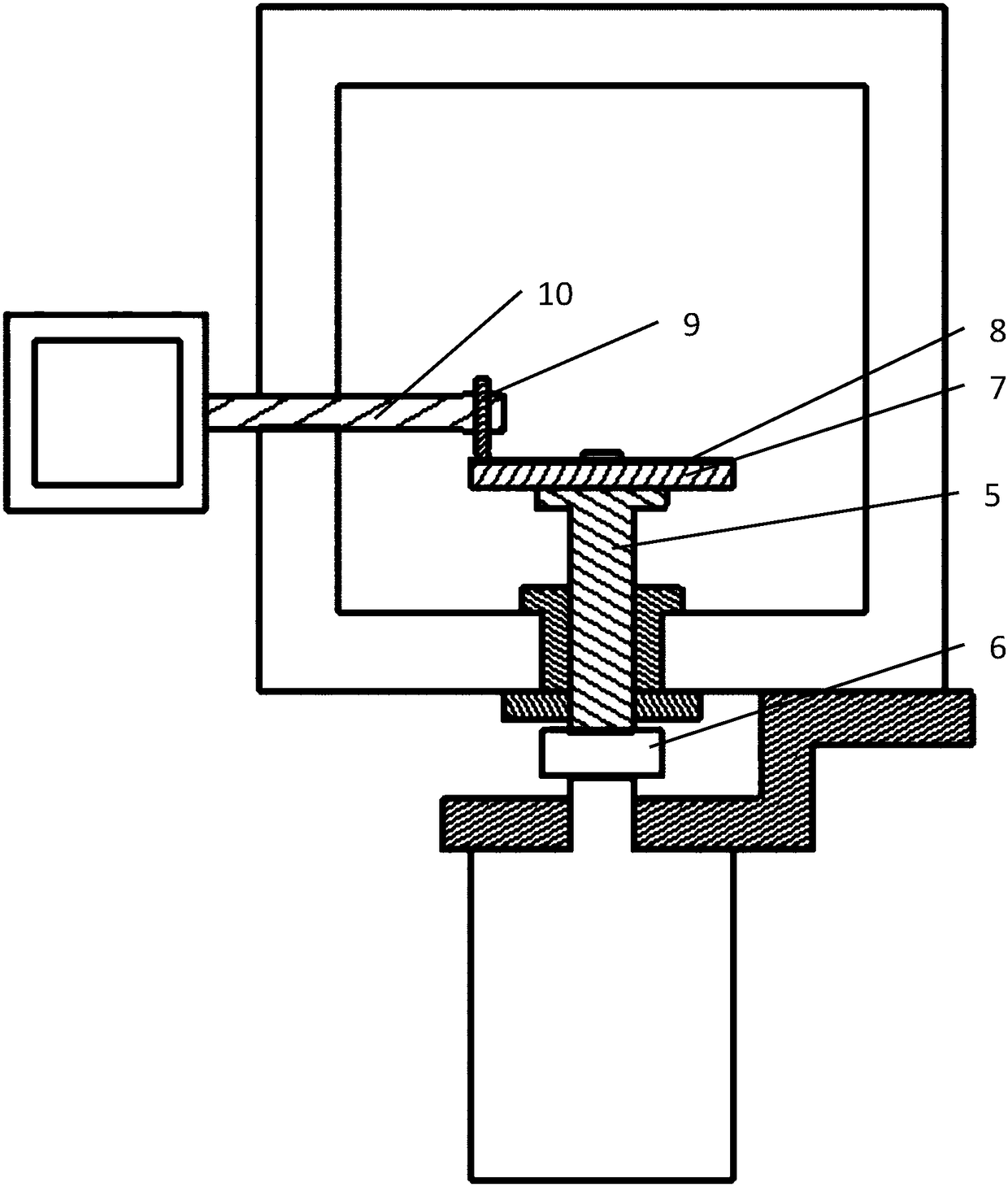

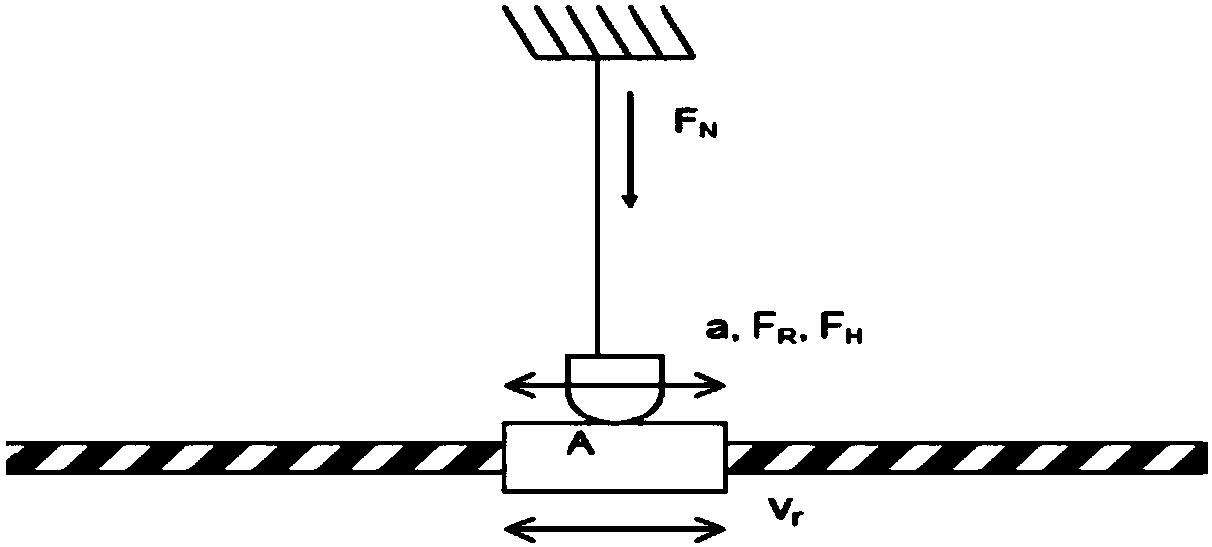

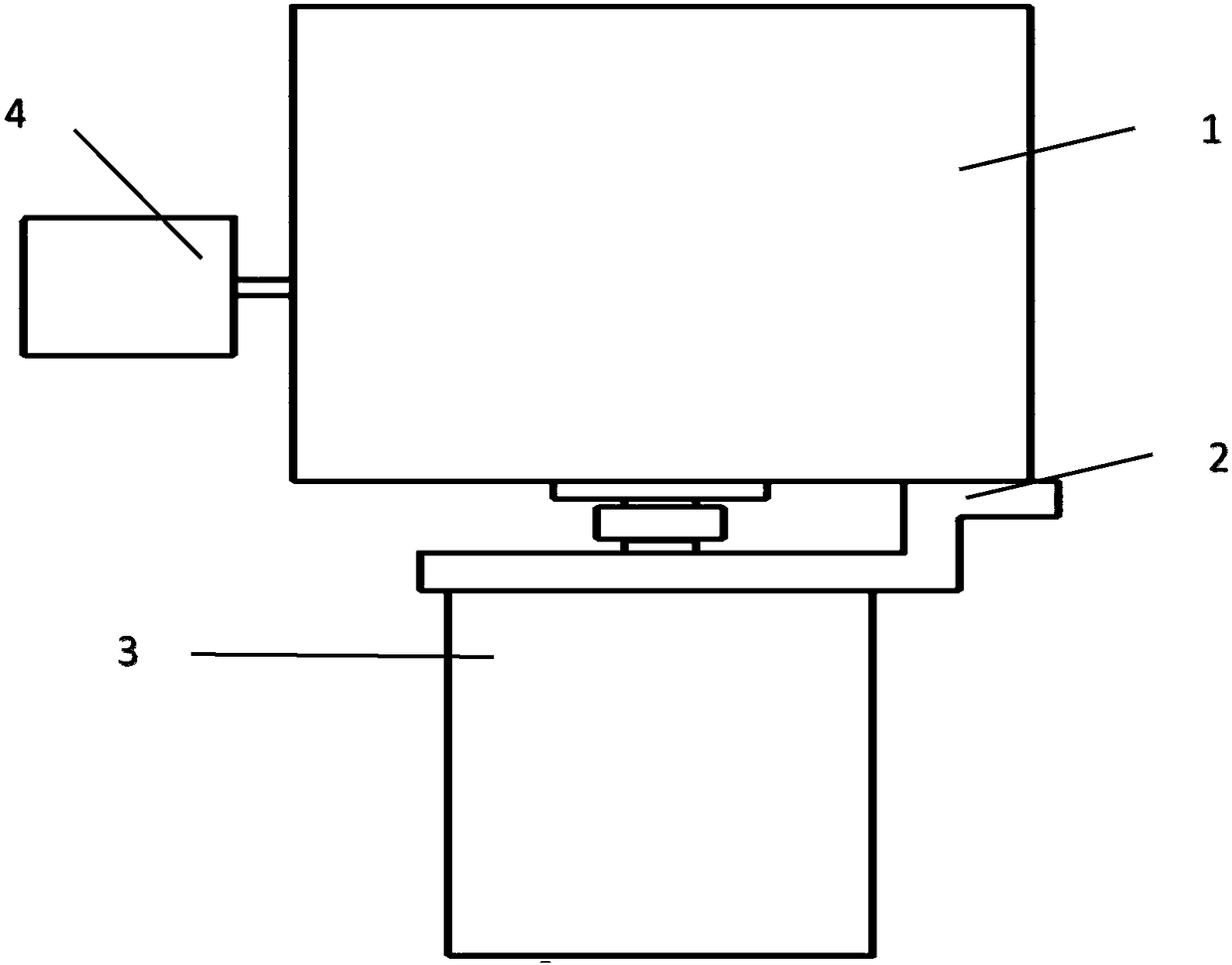

[0033] The main body of the present invention is a constant temperature and humidity environment wear-resisting test box (as attached figure 2 , 3 shown). There is a disc-shaped driving disc 7 with a diameter of 200mm inside the box body 1. One of the materials to be tested is processed into a disc-shaped disc body 8, which is fixed on the driving disc 7 by two screws with disc-shaped gaskets. The lower end of the driving disc 7 is fixed to the driving shaft 5, the driving shaft 5 protrudes out of the casing, the casing 1 is equipped with a flange, and a sealing ring is arranged between the flange and the driving shaft 5 for fixing the driving shaft 5 and sealing effect . The lower part of the box body 1 has a motor fixing bracket 2, which fixes the drive motor 3 on the box body 1, and keeps the motor shaft and the drive shaft 5 in a coaxial state, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com